0Cr23Al5 and 0Cr25Al5 FeCrAl wires represent some of the most reliable solutions for high-temperature and eco-friendly heating systems. At DLX, we specialize in developing and supplying these advanced resistance alloys to meet the growing demand for efficiency, sustainability, and performance across multiple industries.

For more details, pls directly contact us

FeCrAl alloys are iron-based resistance materials enhanced with chromium and aluminum. The addition of chromium provides superior oxidation resistance, while aluminum contributes to the formation of a stable alumina layer that protects the surface under high-temperature operation. Grades such as 0Cr23Al5 and 0Cr25Al5 are particularly well-known for their balance of strength, durability, and energy efficiency.

These wires can operate continuously in extreme environments, withstanding temperatures up to 1350°C, making them indispensable in both industrial and household heating applications. Their long service life reduces replacement costs and enhances overall system sustainability, perfectly aligning with the global shift toward eco-friendly technologies.

Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | ||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

In recent years, industrial heating has undergone a transformation driven by energy efficiency standards, environmental regulations, and the need for cost reduction. Traditional materials often struggle with scaling, oxidation, or limited lifespans under high heat. This has fueled demand for alloys like FeCrAl, which deliver extended service life and stable performance even in harsh environments.

Global market trends show strong growth in sectors such as advanced ceramics, renewable energy, electric vehicle battery manufacturing, and high-efficiency furnaces. These industries increasingly require heating components that can operate at high temperatures with minimal energy loss and reduced environmental impact. FeCrAl wire, particularly 0Cr23Al5 and 0Cr25Al5, is positioned as a key material for these applications.

Comparison Table: 0Cr23Al5 vs 0Cr25Al5 FeCrAl Wire

| Grade | Main Composition (approx.) | Max Operating Temp (°C) | Resistivity (μΩ·m) | Oxidation Resistance | Typical Applications |

|---|---|---|---|---|---|

| 0Cr23Al5 | Fe-Cr(23%)-Al(5%) | 1250 | ~1.35 | High | Household heaters, industrial furnaces |

| 0Cr25Al5 | Fe-Cr(25%)-Al(5%) | 1350 | ~1.40 | Very High | High-temp kilns, ceramics, petrochemical heating |

| FeCrAl Wire | Fe-Cr(20–27%)-Al(4–6%) | 1250–1400 | ~1.35–1.45 | Excellent | Wide industrial heating, eco-heating systems |

Industrial Furnaces: FeCrAl wires are widely used in resistance heating elements for industrial furnaces, ensuring uniform heating and minimal emissions.

Ceramics and Glass: Their ability to withstand repeated thermal cycling makes them ideal for kilns, glass molding, and sintering processes.

Chemical Processing: Resistance to oxidation and corrosive atmospheres allows for reliable operation in chemical reactors and heat treatment systems.

Household Appliances: In electric ovens, toasters, and heaters, FeCrAl wire ensures safety, durability, and efficiency.

Eco-Friendly Heating Systems: With global emphasis on reducing carbon footprints, FeCrAl wire supports green heating solutions by improving energy utilization and lowering overall consumption.

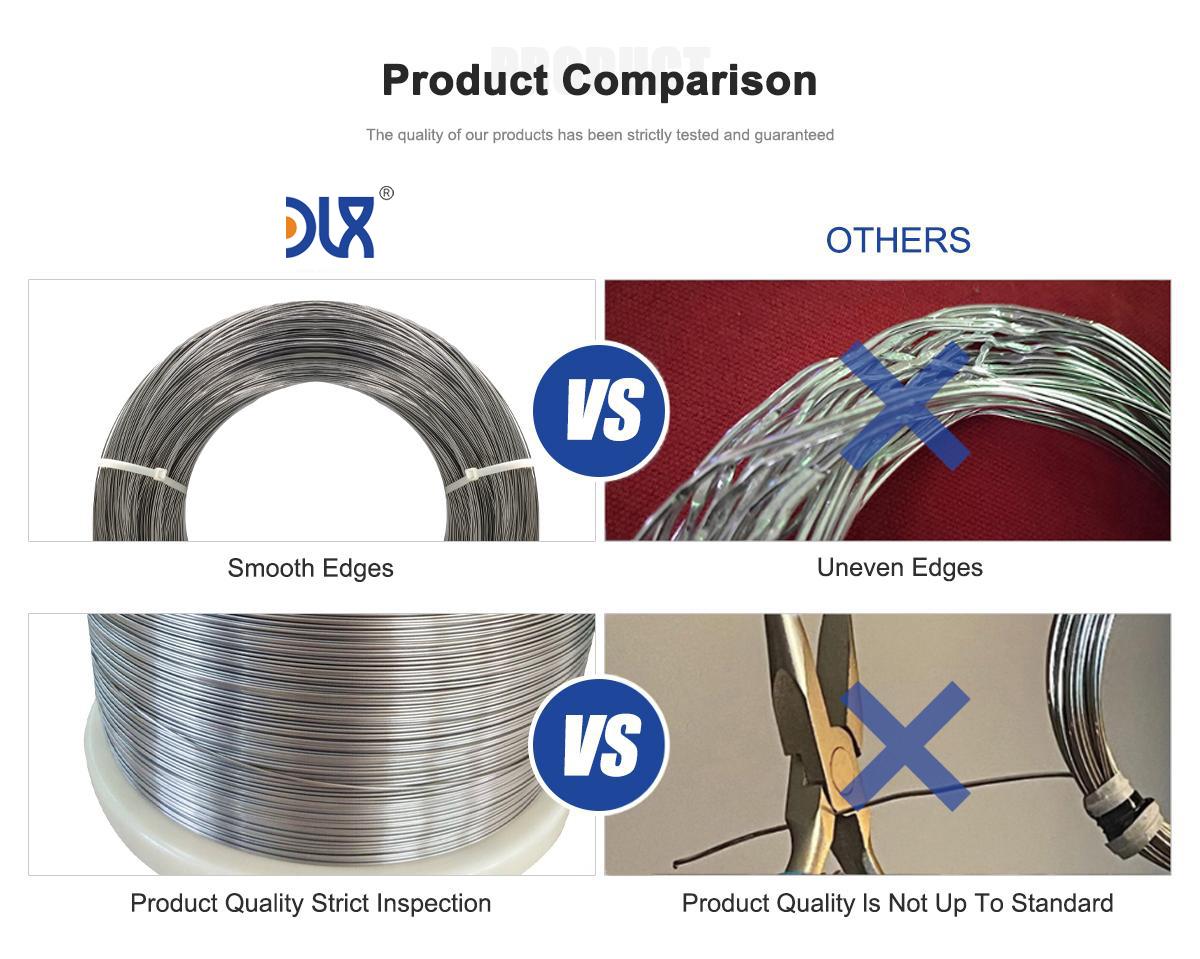

Company Comparison

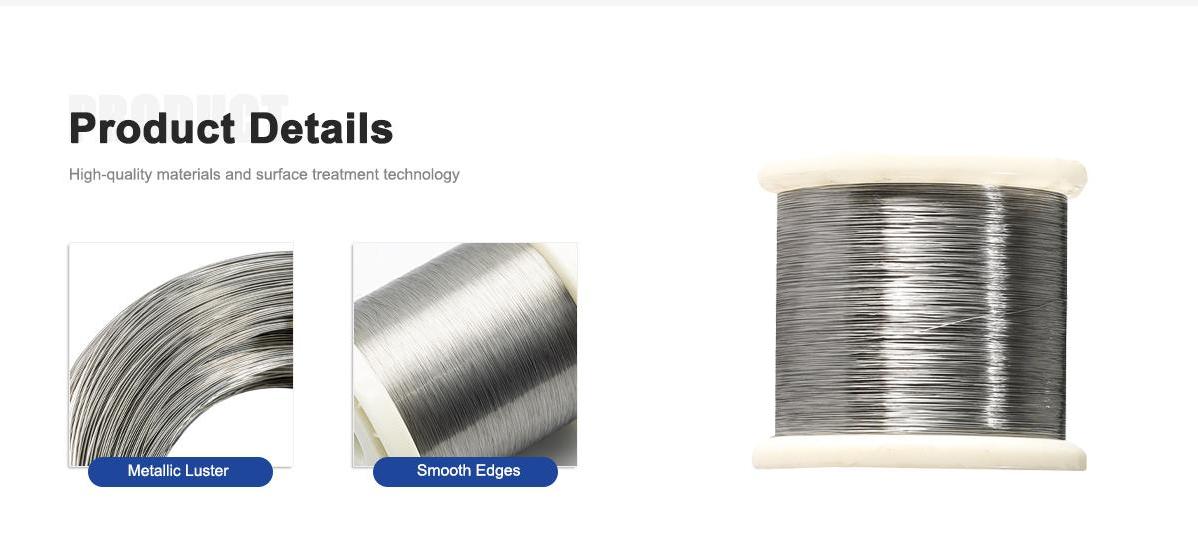

Many suppliers offer FeCrAl products, but DLX stands out through its consistent quality, innovation, and service. While others may provide standard-grade wires, DLX focuses on precision alloy control, advanced production technology, and rigorous quality testing. This ensures that each batch of wire delivers the expected resistivity, oxidation resistance, and long-term performance.

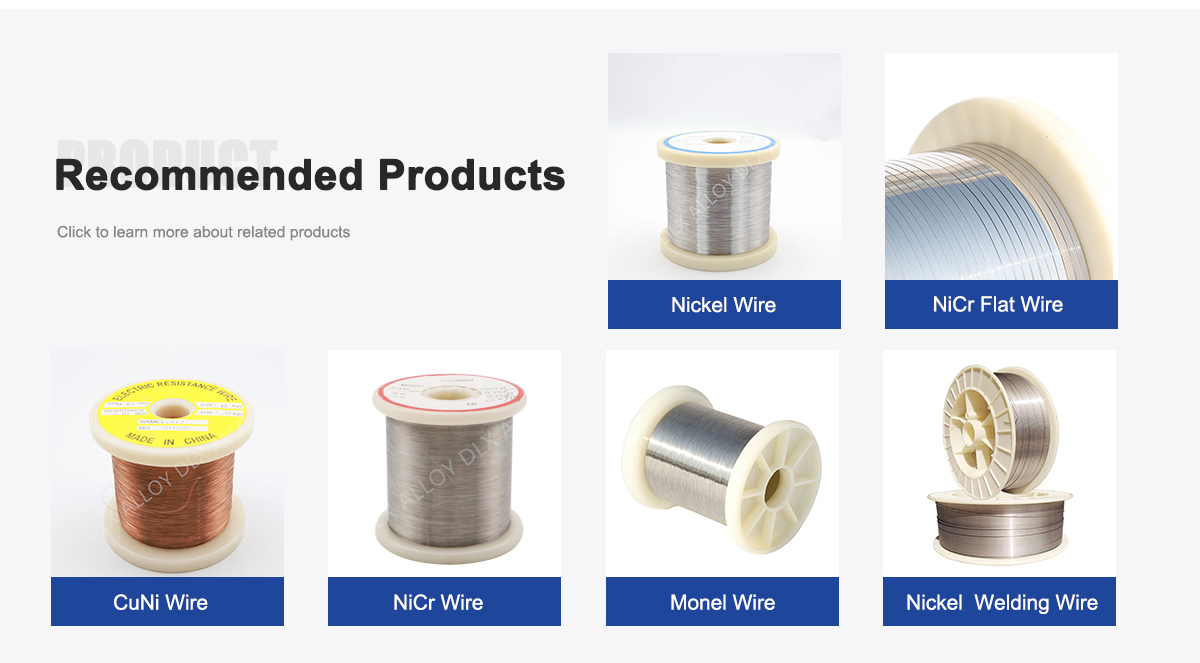

Furthermore, DLX invests in customization. We understand that clients in different industries face unique challenges, whether it’s specific diameters for fine heating elements, strips for furnace linings, or tailored resistivity requirements. By providing made-to-order solutions, DLX helps clients achieve efficiency gains and reduce maintenance downtime.

Material Excellence: Strict alloy composition control for consistent performance.

Eco-Focused Solutions: Products designed for energy-efficient and sustainable systems.

Customization: Flexible sizes, forms, and packaging based on customer requirements.

Industry Expertise: Years of experience supplying to high-demand industries worldwide.

Reliable Service: Fast delivery, technical support, and long-term partnerships.

Conclusion

The future of industrial heating is moving toward efficiency, sustainability, and reliability. FeCrAl alloys like 0Cr23Al5 and 0Cr25Al5 are at the heart of this transformation. At DLX, we are committed to driving innovation in heating technology with our high-quality alloy wires. By combining advanced materials, eco-conscious design, and tailored solutions, we empower industries to achieve better performance with reduced environmental impact.

About Us:

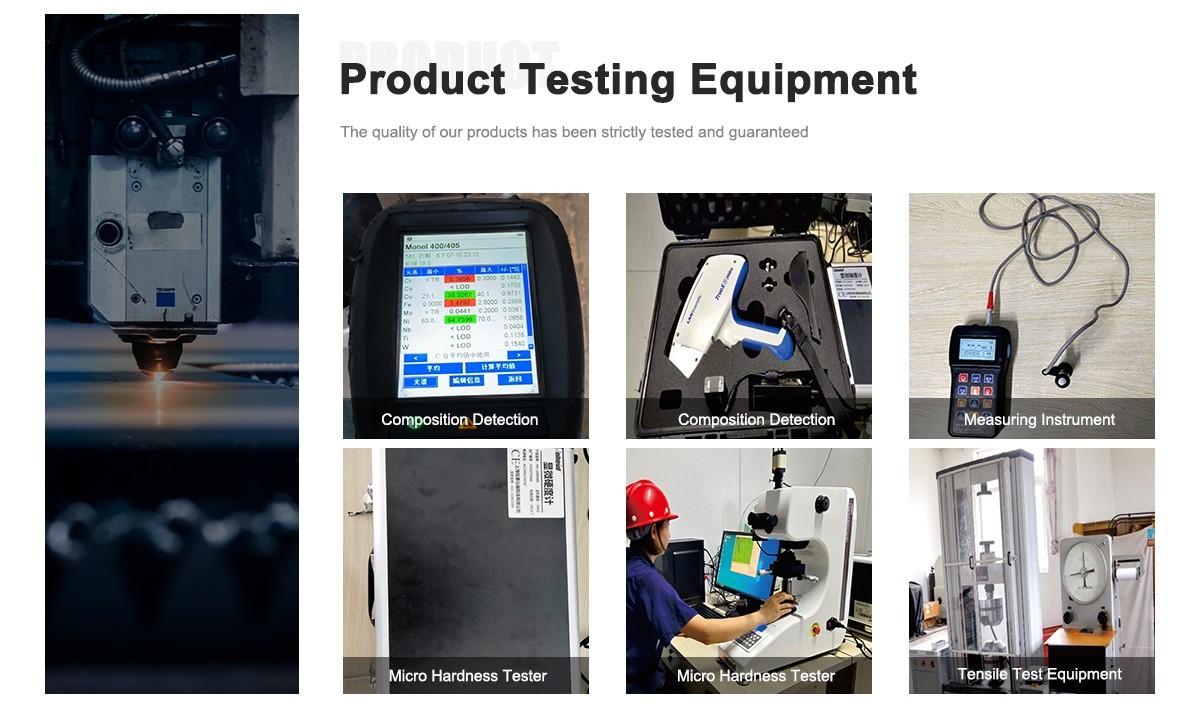

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is 0Cr23Al5 0Cr25Al5 FeCrAl wire made of?

It is made of an iron-chromium-aluminum alloy with controlled proportions of Fe, Cr, and Al.What is the maximum operating temperature of this wire?

It can work continuously up to around 1250–1400°C depending on grade.Is this wire resistant to oxidation?

Yes, it has excellent oxidation resistance due to its protective alumina film.Can it be used in eco-friendly heating systems?

Yes, it is widely applied in energy-efficient and environmentally friendly heating equipment.What industries use FeCrAl wire?

Metallurgy, ceramics, chemical processing, glass, electronics, and home appliances.How does it compare to nickel-chromium wire?

FeCrAl wire has higher maximum temperature resistance and longer service life under certain conditions.Is it available in different diameters and forms?

Yes, it can be supplied as wire, strip, or rod in various sizes.Does DLX provide customized production?

Yes, DLX offers tailored specifications based on customer requirements.