The demand for high-performance heating materials has never been greater. 0Cr15Al5 FeCrAl resistance heating wire stands out as a versatile alloy that balances performance, cost, and reliability, making it a trusted material for industrial and domestic heating systems.

For more details, pls directly contact us

0Cr15Al5 belongs to the family of FeCrAl alloys. It is a ferritic alloy with 15% chromium and 5% aluminum, offering high resistance to oxidation and corrosion at elevated temperatures. The protective alumina layer formed during heating makes it particularly suitable for long-term use in oxidizing atmospheres. Compared with nickel-chromium wires, FeCrAl wires like 0Cr15Al5 are more affordable while providing higher temperature capabilities, making them an efficient solution for industries that prioritize both durability and cost control.

Alloy Nomenclature Performance | 0Cr25Al5 | 0Cr21Al6 | 0Cr21Al4 | |||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

The wire finds applications across a wide range of industries:

Industrial furnaces – for heating coils and elements requiring stability above 1100°C.

Ceramic kilns and glass production – where consistent high temperatures are needed.

Resistors – offering precise electrical resistance properties.

Household appliances – such as ovens, toasters, and heaters.

Laboratory equipment – where reliability and controlled heating are essential.

Its ability to combine heat resistance with mechanical strength ensures stable performance in demanding environments.

Comparison Table: 0Cr15Al5 vs Other FeCrAl Alloys

| Alloy Grade | Composition (Fe-Cr-Al) | Max Service Temp (°C) | Oxidation Resistance | Mechanical Strength | Applications | Equivalent Grades (USA/Germany/France/Russia) |

|---|---|---|---|---|---|---|

| 0Cr15Al5 | Fe-15Cr-5Al | 1150–1200 | Good | Good | Industrial furnaces, heaters, kilns, appliances | FeCrAl / X15CrAl5 / Z15CAL5 / Х15Ю5 |

| 0Cr21Al6 | Fe-21Cr-6Al | 1250 | Excellent | High | High-temp heating coils, industrial kilns | FeCrAl / X21CrAl6 / Z21CAL6 / Х21Ю6 |

| 0Cr23Al5 | Fe-23Cr-5Al | 1250 | Excellent | High | Resistors, industrial ovens, household heaters | FeCrAl / X23CrAl5 / Z23CAL5 / Х23Ю5 |

| 0Cr25Al5 | Fe-25Cr-5Al | 1300 | Very High | High | Metallurgy, furnaces with extreme heating conditions | FeCrAl / X25CrAl5 / Z25CAL5 / Х25Ю5 |

| 0Cr27Al7Mo2 | Fe-27Cr-7Al-2Mo | 1400 | Superior | Very High | Aerospace heating, high-performance furnaces | FeCrAlMo / X27CrAl7Mo2 / Z27CAL7Mo2 / Х27Ю7М2 |

The heating industry is shifting toward efficiency and sustainability. With increasing global demand for energy-efficient furnaces and environmentally friendly solutions, FeCrAl alloys are gaining traction. 0Cr15Al5, in particular, is attractive to industries seeking reliable mid-to-high temperature solutions without overinvesting in more expensive alloys.

Additionally, stricter regulations on energy efficiency are driving innovation in heating elements. Manufacturers are seeking materials that provide longer service life, reduced downtime, and consistent performance. FeCrAl alloys are answering this demand by outperforming traditional resistance materials.

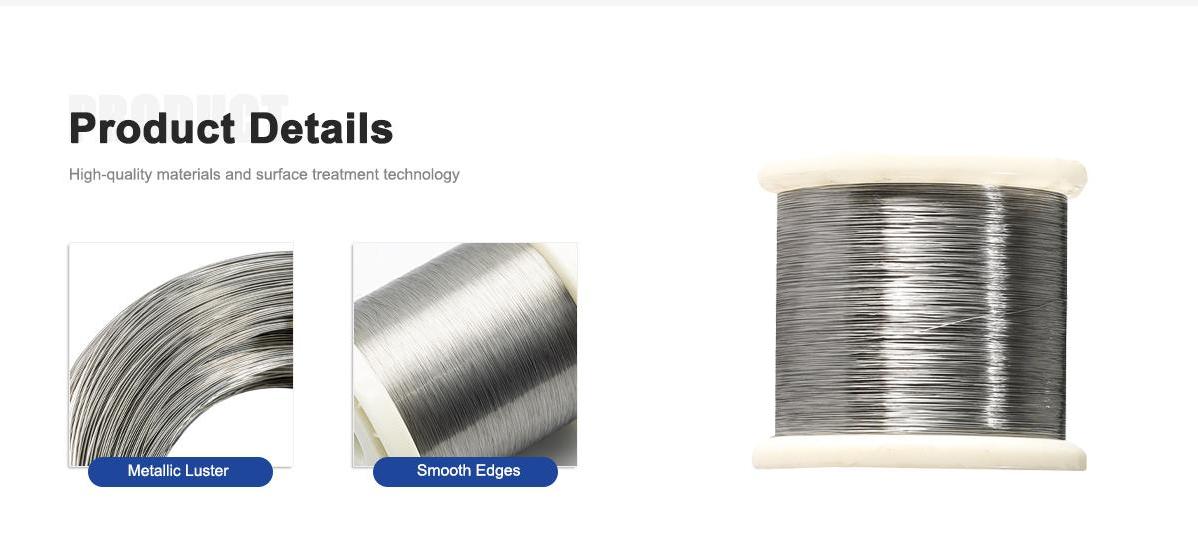

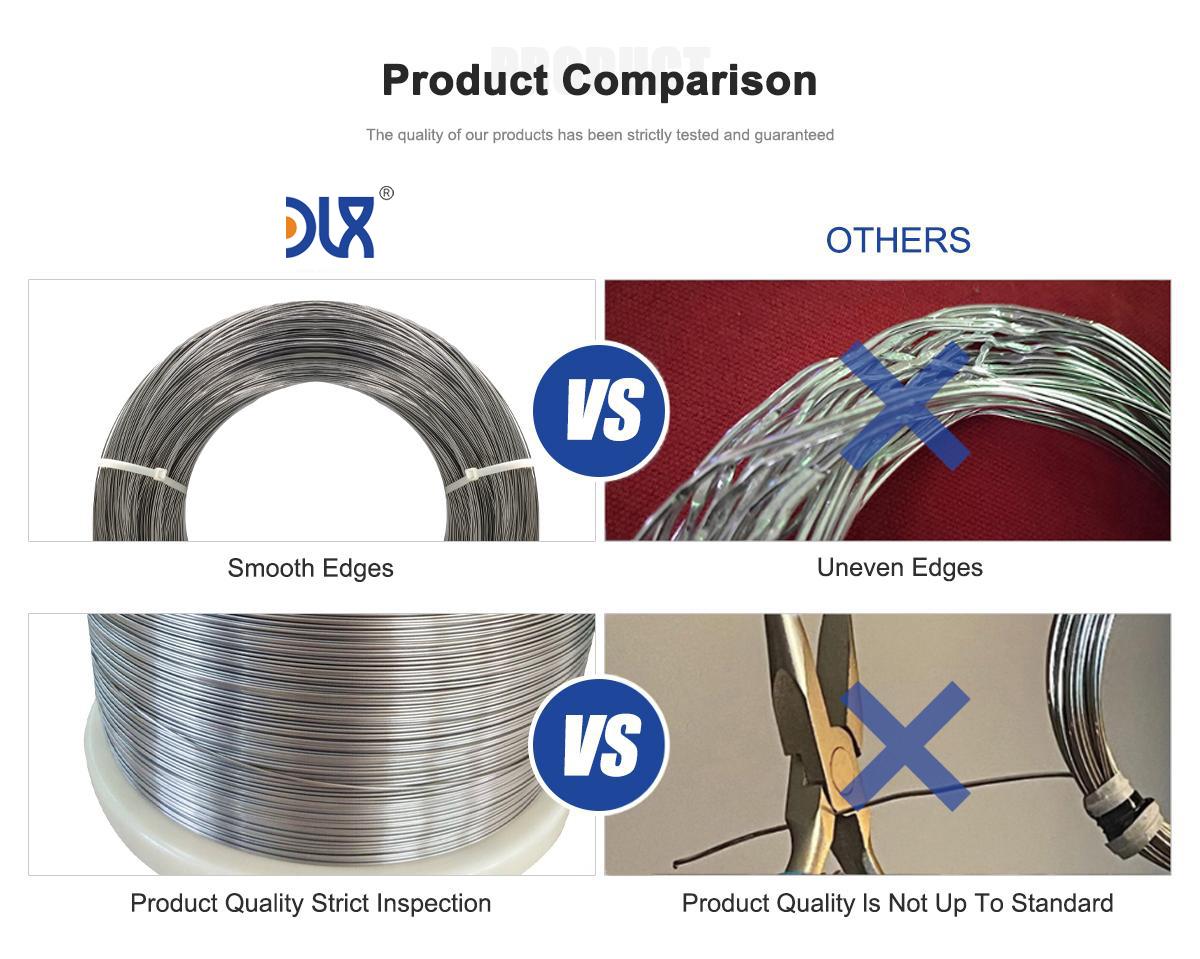

In today’s competitive market, suppliers vary widely in quality and reliability. Many offer standard alloys, but not all ensure strict consistency in composition and performance. At DLX, we distinguish ourselves by delivering resistance heating wires that are not only precise in chemical composition but also manufactured under strict quality control systems. This ensures every coil or spool meets international standards and customer requirements.

DLX Advantages

Customization: We supply 0Cr15Al5 wire in a variety of diameters, shapes, and packaging forms. Whether clients need spools, straight lengths, or coils, DLX adapts to specific requirements.

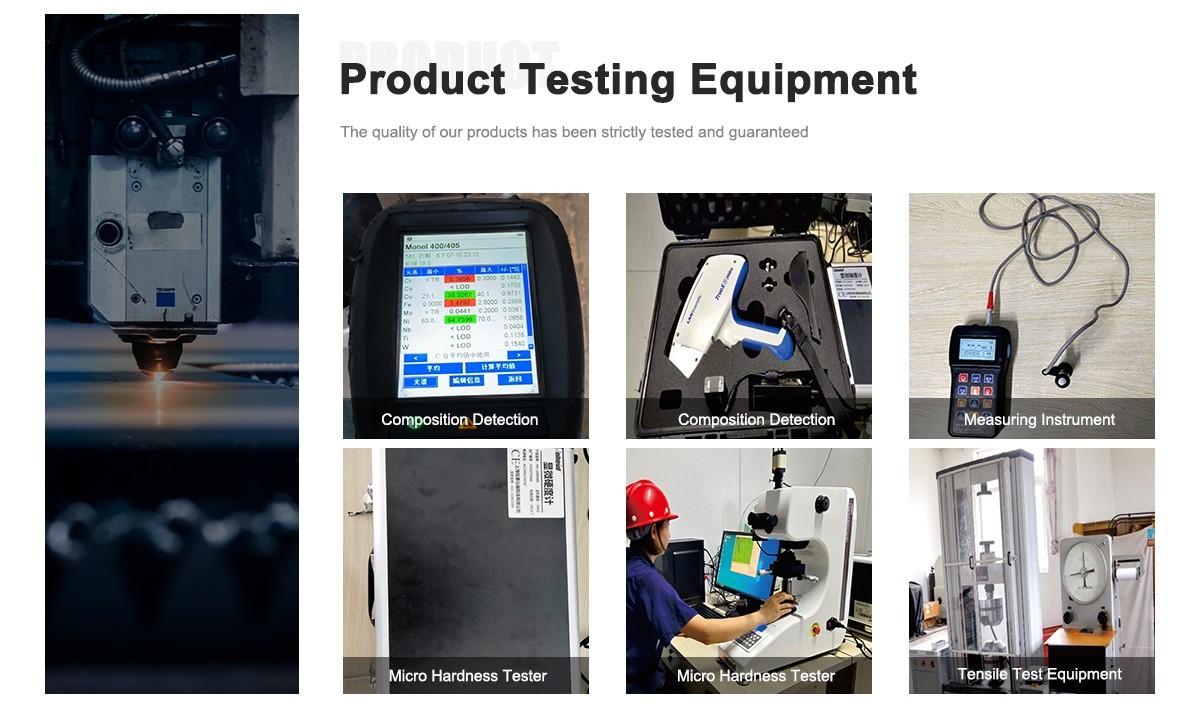

Quality Assurance: Each batch undergoes strict testing to guarantee stable resistance, mechanical strength, and oxidation resistance.

Competitive Pricing: By optimizing production, we provide cost-effective solutions without compromising quality.

Technical Support: Our team assists clients with selecting the right alloy and designing heating elements for maximum efficiency.

Fast Delivery: Global customers benefit from reliable lead times and prompt logistics.

When compared with general market suppliers, DLX offers more than just a product — we deliver solutions that enhance efficiency, extend equipment service life, and reduce operational costs. This customer-first approach makes DLX a trusted partner in the heating industry.

0Cr15Al5 FeCrAl resistance heating wire is a proven material for industrial furnaces and other heating applications. With its balance of temperature resistance, oxidation stability, and cost-effectiveness, it continues to play a vital role in modern thermal systems. At DLX, we are committed to helping our customers succeed by providing high-quality, customized FeCrAl wires backed by technical expertise and reliable service.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is the chemical composition of 0Cr15Al5 wire?

It mainly consists of iron with around 15% chromium and 5% aluminum, designed for high-temperature resistance and oxidation stability.What is the maximum operating temperature of 0Cr15Al5 alloy wire?

The alloy can operate continuously up to 1150–1200°C, depending on the furnace environment and design.Where is 0Cr15Al5 resistance wire commonly used?

It is widely applied in industrial furnaces, ceramic kilns, glass processing, resistors, and electric household heating appliances.What makes 0Cr15Al5 different from other FeCrAl alloys?

Compared with higher-grade alloys like 0Cr21Al6 or 0Cr27Al7Mo2, 0Cr15Al5 offers a more cost-effective solution with reliable performance for medium-to-high temperature applications.Does 0Cr15Al5 wire have strong oxidation resistance?

Yes, the aluminum content forms a dense protective Al₂O₃ layer, which provides long-lasting oxidation resistance at elevated temperatures.Which industries benefit most from 0Cr15Al5 wire?

Metallurgy, petrochemical, glass, ceramics, and appliance manufacturing industries rely heavily on this wire for heating elements.Can 0Cr15Al5 FeCrAl wire be customized?

Yes, it can be supplied as round wire, flat wire, or strip, in spools, coils, or straight cut lengths depending on customer requirements.What are the international equivalents of 0Cr15Al5 alloy?

USA: FeCrAl-based equivalents

Germany: X15CrAl5

France: Z15CAL5

Russia: Х15Ю5 (Kh15Yu5)