0Cr15Al5 alloy wire is one of the most reliable choices for industries that need stable heating performance at elevated temperatures. As a ferritic FeCrAl alloy, it combines chromium and aluminum in balanced proportions, providing durability, oxidation resistance, and strong electrical resistance properties.

For more details, pls directly contact us

The wire is composed of iron with 15% chromium and 5% aluminum. This composition provides two major benefits: high resistivity and strong oxidation resistance. When heated, aluminum in the alloy forms a stable alumina layer on the surface. This thin yet tough oxide film protects the wire from further oxidation, extending its lifespan in harsh, high-temperature environments.

Compared to nickel-chromium wires, FeCrAl alloys like 0Cr15Al5 offer a higher operating temperature range and a longer service life, while being more cost-effective. This makes it a preferred material for applications where both performance and economic value are critical.

Applications

0Cr15Al5 alloy wire serves in a wide variety of heating systems, including:

Industrial furnaces: heating elements for steel, ceramics, and thermal processing.

Ceramic kilns and glass plants: stable heating under prolonged high-temperature cycles.

Household appliances: electric ovens, toasters, and heaters.

Laboratory equipment: furnaces and kilns used for research and testing.

Resistors: electrical components requiring precise resistance values.

Its adaptability allows manufacturers to produce it in different forms such as round wire, strip, or flat wire, and it can be wound or formed into coils to match different designs.

Alloy Nomenclature Performance | 0Cr25Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | ||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

The global shift toward higher energy efficiency and sustainable production is driving demand for advanced heating materials. FeCrAl alloys like 0Cr15Al5 are gaining recognition because they provide both technical and economic advantages. The growing need for durable, long-lasting heating elements is pushing industries to move away from traditional materials that degrade faster at high temperatures.

In addition, industries like metallurgy, ceramics, and renewable energy require heating solutions that minimize downtime. 0Cr15Al5 is well-positioned to meet this demand because of its stable properties, long service life, and wide compatibility across heating systems.

Comparison Table: 0Cr15Al5 vs Other FeCrAl Alloys

| Alloy Grade | Composition (Fe-Cr-Al) | Max Service Temp (°C) | Oxidation Resistance | Mechanical Strength | Applications | Equivalent Grades (USA/Germany/France/Russia) |

|---|---|---|---|---|---|---|

| 0Cr15Al5 | Fe-15Cr-5Al | 1150–1200 | Good | Good | Furnaces, appliances, resistors, kilns | FeCrAl / X15CrAl5 / Z15CAL5 / Х15Ю5 |

| 0Cr21Al6 | Fe-21Cr-6Al | 1250 | Excellent | High | Heating coils, high-temp industrial furnaces | FeCrAl / X21CrAl6 / Z21CAL6 / Х21Ю6 |

| 0Cr23Al5 | Fe-23Cr-5Al | 1250 | Excellent | High | Resistors, industrial ovens | FeCrAl / X23CrAl5 / Z23CAL5 / Х23Ю5 |

| 0Cr25Al5 | Fe-25Cr-5Al | 1300 | Very High | High | Metallurgy, heavy-duty furnace systems | FeCrAl / X25CrAl5 / Z25CAL5 / Х25Ю5 |

| 0Cr27Al7Mo2 | Fe-27Cr-7Al-2Mo | 1400 | Superior | Very High | Aerospace, extreme heating conditions | FeCrAlMo / X27CrAl7Mo2 / Z27CAL7Mo2 / Х27Ю7М2 |

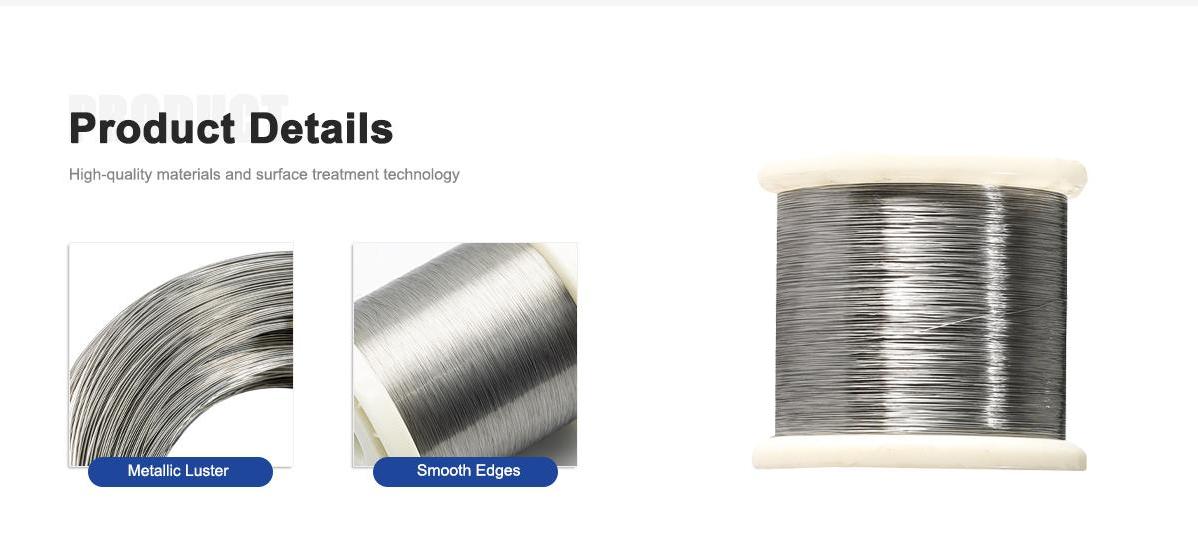

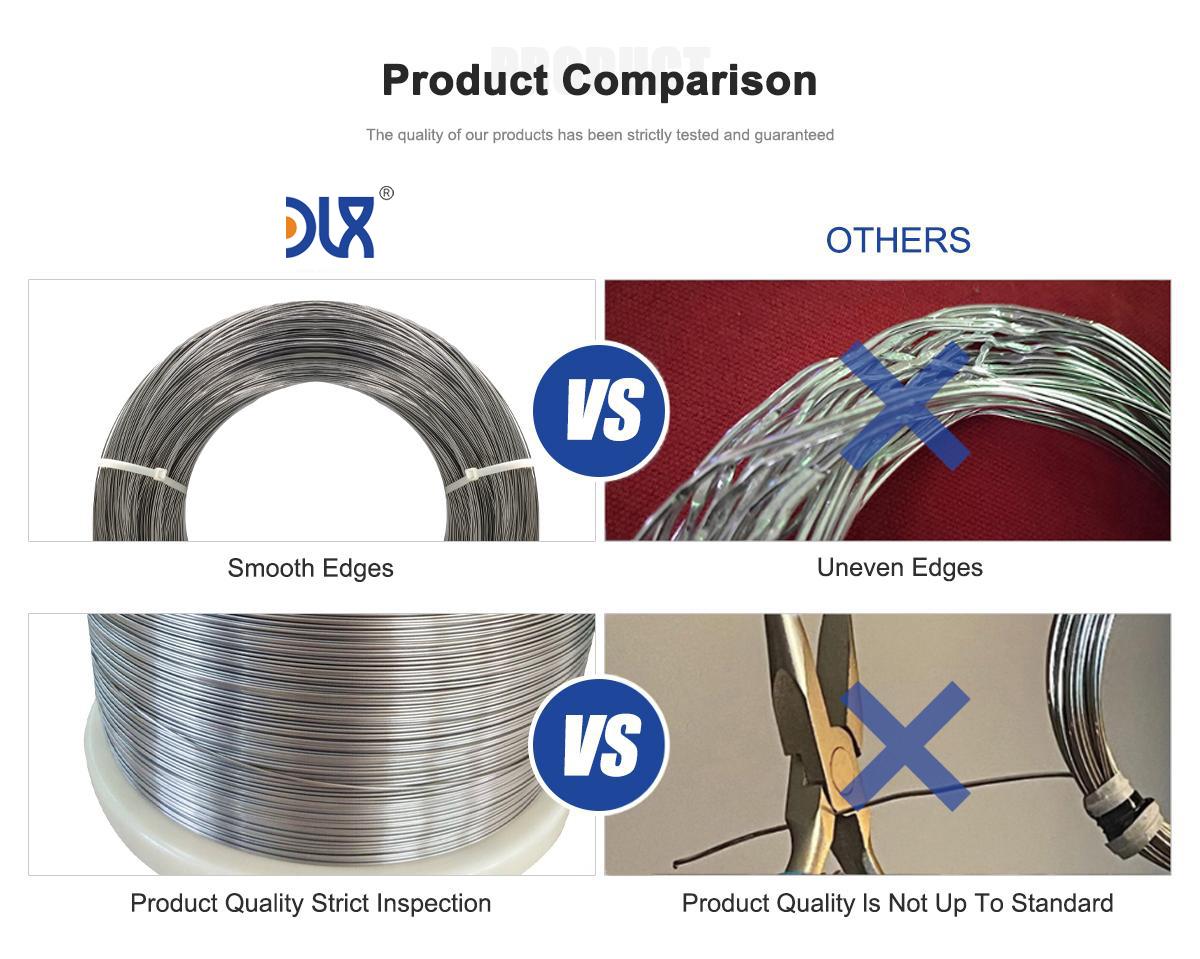

In today’s marketplace, customers face many options when sourcing resistance alloys. However, consistency, reliability, and customization are not always guaranteed. At DLX, we ensure that every spool or coil of 0Cr15Al5 wire meets exacting standards for composition, resistivity, and performance.

We understand that heating systems demand precision. That is why DLX focuses on strict quality control and technical guidance, helping customers choose the best wire for their applications. Whether clients need small-diameter wires for compact heating devices or larger forms for industrial furnaces, DLX provides tailored solutions.

DLX Advantages

High consistency: Every batch undergoes rigorous testing to ensure uniform resistivity and performance.

Customization: Wide range of diameters, packaging, and delivery formats.

Competitive pricing: Efficient production and sourcing allow us to provide cost-effective options.

Technical expertise: Our team assists with material selection and element design to maximize efficiency.

Reliable delivery: Global customers rely on our dependable logistics and timely shipments.

By choosing DLX, customers gain more than just alloy wire—they gain a partner dedicated to improving system efficiency, reducing maintenance costs, and ensuring long-lasting heating performance.

Conclusion

0Cr15Al5 alloy wire continues to be a trusted material in industrial furnaces, kilns, and electric heating systems. With strong oxidation resistance, high-temperature endurance, and proven cost efficiency, it remains one of the most practical solutions for heating applications worldwide. DLX stands ready to deliver this alloy in the highest quality, offering clients tailored solutions and long-term reliability.

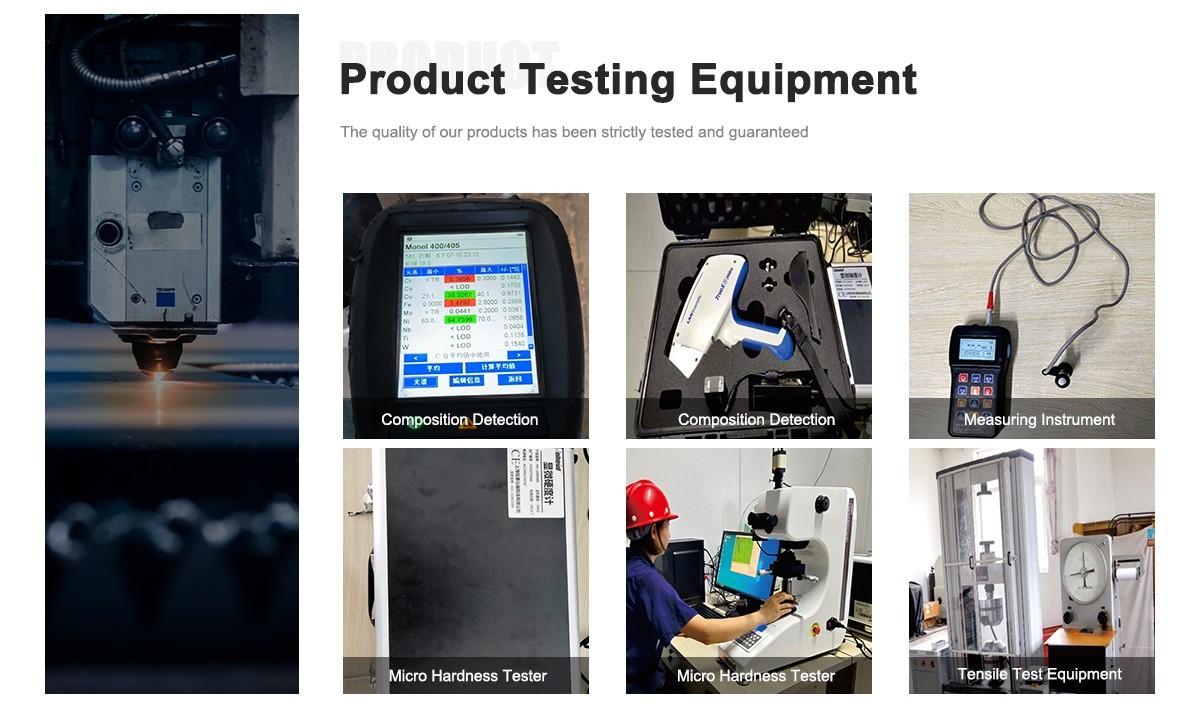

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is the composition of 0Cr15Al5 alloy wire?

It is an FeCrAl alloy with approximately 15% chromium and 5% aluminum, designed for high-temperature heating applications.What temperature can 0Cr15Al5 wire withstand?

It performs reliably in continuous use up to 1150–1200°C.What industries commonly use 0Cr15Al5 alloy wire?

Industries such as metallurgy, ceramics, petrochemicals, and glass production frequently use it for heating elements.What are the benefits of 0Cr15Al5 compared to other resistance wires?

It offers a strong balance of high-temperature resistance, oxidation resistance, and cost-effectiveness compared to nickel-based wires.Does 0Cr15Al5 have good oxidation resistance?

Yes, the aluminum forms a stable Al₂O₃ layer that protects against oxidation even at high operating temperatures.Can 0Cr15Al5 be customized for specific applications?

Yes, it can be manufactured as wire, strip, or rod, and supplied in coils, spools, or cut lengths according to customer needs.What are the international equivalent grades of 0Cr15Al5?

Germany: X15CrAl5

France: Z15CAL5

Russia: Х15Ю5 (Kh15Yu5)

USA: FeCrAl-based alloys of similar composition

Why choose 0Cr15Al5 for heating elements?

Its ability to combine durability, high performance, and economic efficiency makes it a preferred material for heating systems.