When it comes to designing and manufacturing heating systems, the material behind the wire matters as much as the engineering itself. 1Cr13Al4 FeCrAl heating wire has become one of the most reliable choices for electric heaters, household appliances, and a wide range of industrial applications. Its unique combination of iron, chromium, and aluminum gives it high electrical resistance, superior oxidation resistance, and remarkable longevity at elevated temperatures.

At DLX, we focus on delivering FeCrAl heating wire that goes beyond the basics. Our customers in appliance manufacturing, metallurgy, and industrial heating sectors rely on us not just for material supply, but for solutions that guarantee consistent performance, even under the harshest conditions.

For more details, pls directly contact us

1Cr13Al4 is part of the FeCrAl alloy family, known for its excellent resistance to oxidation and ability to operate at high temperatures without significant degradation. The addition of aluminum forms a protective oxide layer when exposed to heat, shielding the wire from further oxidation and extending service life. Compared to other heating alloys, this grade provides a balance between durability, efficiency, and cost-effectiveness.

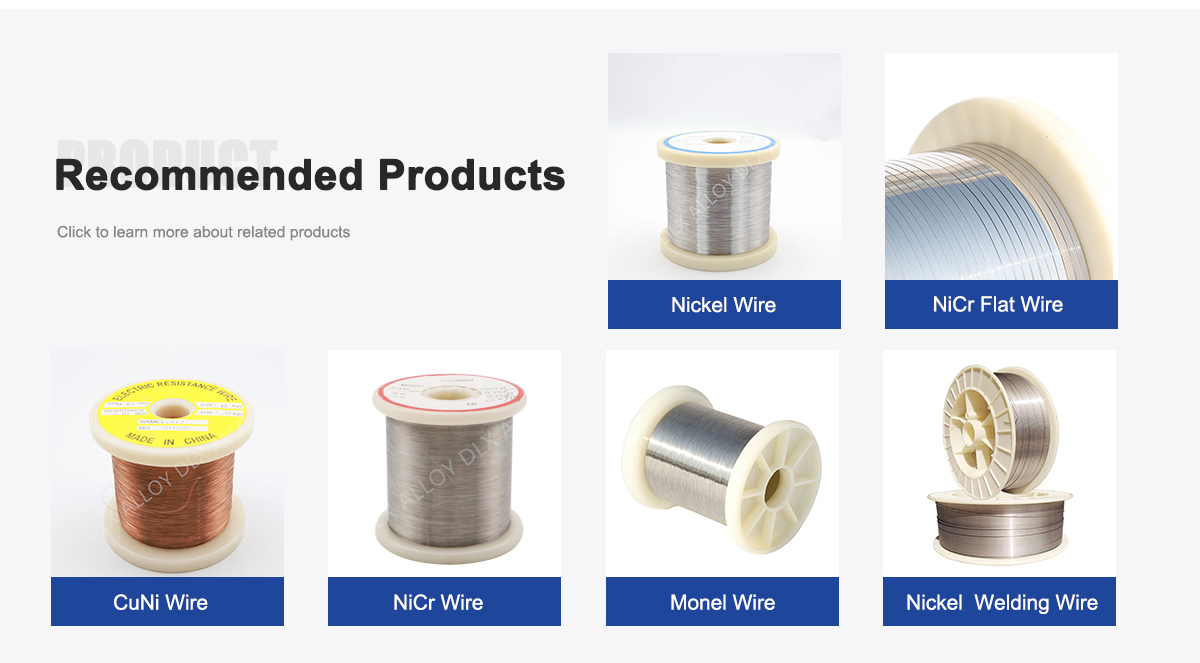

The wire is available in multiple forms: spools for automated production, coils for custom heating elements, and cut lengths tailored for direct use. Its density and resistivity make it suitable for designing efficient heating systems that require both precision and energy savings.

Alloy Nomenclature Performance | 0Cr21Al6 | 0Cr21Al4 | 0Cr21Al6Nb | |||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

The versatility of 1Cr13Al4 FeCrAl heating wire is one of the reasons it has become an industry standard. In household appliances, it powers electric ovens, toasters, kettles, and space heaters. In industrial sectors, it plays a critical role in furnaces, kilns, ceramic processing equipment, and glass production lines. Its stability at high temperatures allows manufacturers to design compact yet powerful heating solutions.

Another key advantage is its ability to operate continuously in demanding conditions. While some materials suffer from creep or structural changes at elevated temperatures, FeCrAl maintains its integrity, ensuring longer intervals between replacements and reducing downtime in industrial setups.

Industry Trends

The demand for efficient heating materials is steadily rising as industries and households seek energy-saving solutions. Global regulations encouraging efficiency and durability in electrical appliances are pushing manufacturers to adopt materials like FeCrAl wire. The trend toward electrification in heating—moving away from fossil fuel-based systems—further strengthens the demand.

Industrial furnaces, especially in metallurgy and ceramics, are expanding their use of FeCrAl wire due to its ability to handle higher temperatures without costly replacements. Meanwhile, appliance makers continue to choose it for its combination of reliability, affordability, and adaptability.

Comparison Table: 1Cr13Al4 FeCrAl Heating Wire vs. NiCr Heating Wire

| Parameter | 1Cr13Al4 FeCrAl Heating Wire | NiCr Heating Wire |

|---|---|---|

| Base Composition | Iron-Chromium-Aluminum | Nickel-Chromium |

| Max Operating Temp | Up to ~1250°C | Up to ~1100°C |

| Oxidation Resistance | Excellent | Good |

| Service Life at High Temp | Longer | Moderate |

| Density (g/cm³) | ~7.2 | ~8.4 |

| Electrical Resistivity (Ω·mm²/m) | 1.35–1.45 | 1.09–1.18 |

| Cost Efficiency | More cost-effective | Higher material cost |

| Common Applications | Heaters, furnaces, appliances | Heaters, lab equipment |

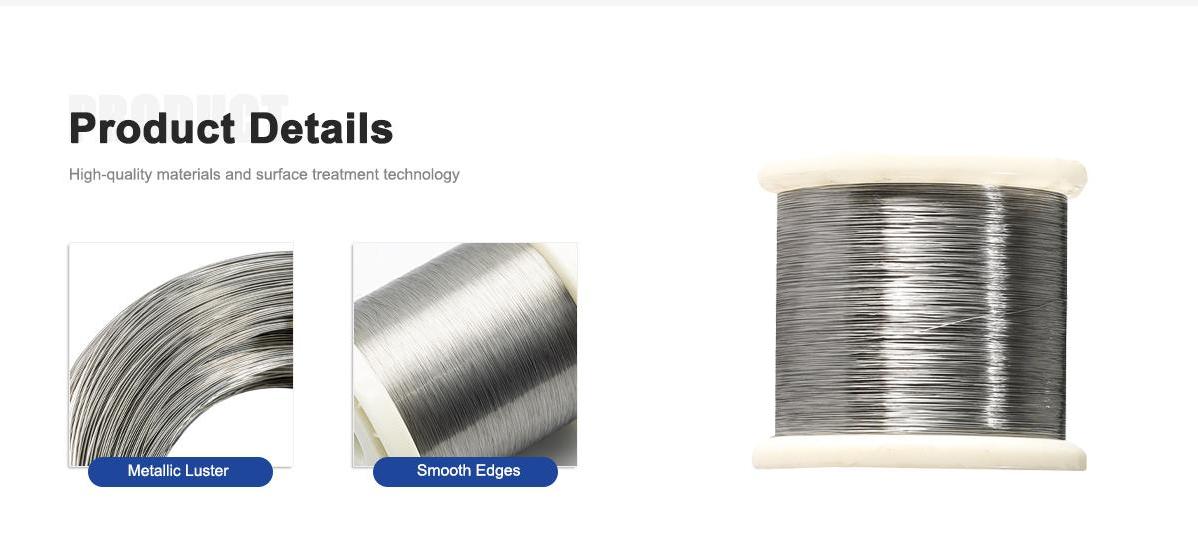

While many suppliers provide FeCrAl wire, DLX stands out by offering precision, quality assurance, and a global outlook. We maintain strict control over composition and tolerance, ensuring each batch of 1Cr13Al4 wire meets international standards. For clients, this means predictable performance, reduced quality concerns, and improved production efficiency.

Our competitive pricing strategy ensures that customers get maximum value, especially in large-scale production where material costs directly affect profitability. Beyond supply, our technical team supports clients in choosing the right diameter, resistance, and form factor for their applications, making DLX not just a supplier but a partner in innovation.

We also understand the importance of delivery timelines. Our logistics network is optimized to provide fast and secure shipment worldwide, helping customers avoid unnecessary delays in production schedules.

Company Comparison

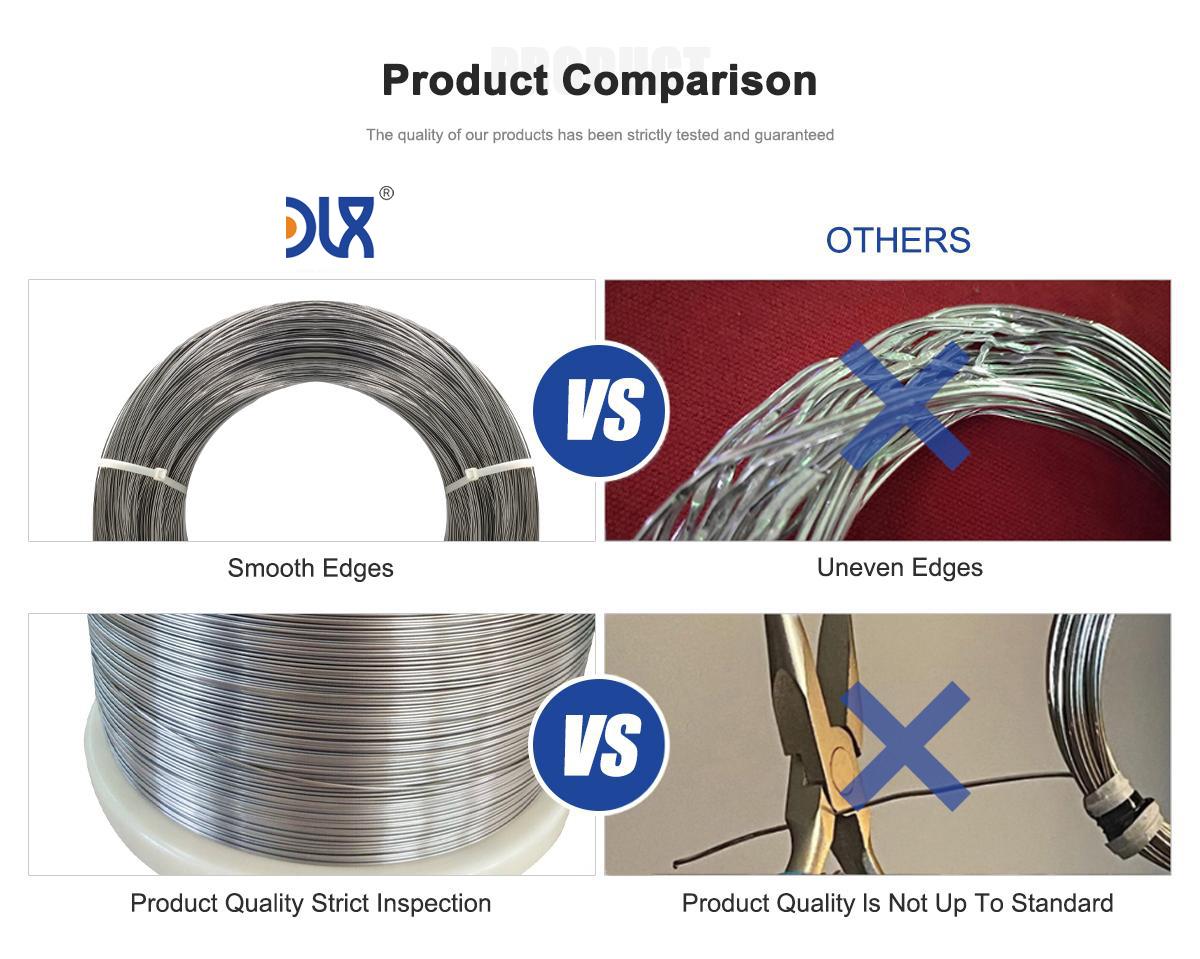

Compared to general suppliers, DLX provides a clear edge in three main areas:

Consistency: Every wire we supply undergoes rigorous quality checks.

Customization: Clients can get tailored solutions for unique heating designs.

Support: Our team provides ongoing guidance, ensuring optimal use of the material.

This combination is why industries across different regions continue to choose DLX as their preferred partner for FeCrAl heating wire.

Conclusion

1Cr13Al4 FeCrAl heating wire has proven itself as an indispensable material in electric heaters, home appliances, and industrial applications. Its ability to resist oxidation, maintain strength at high temperatures, and provide cost-effective performance makes it a top choice for manufacturers.

At DLX, we take pride in delivering not just material but also the expertise and reliability our clients need. As industries continue to evolve toward more energy-efficient and durable solutions, DLX is committed to leading the way with heating wires that meet tomorrow’s demands today.

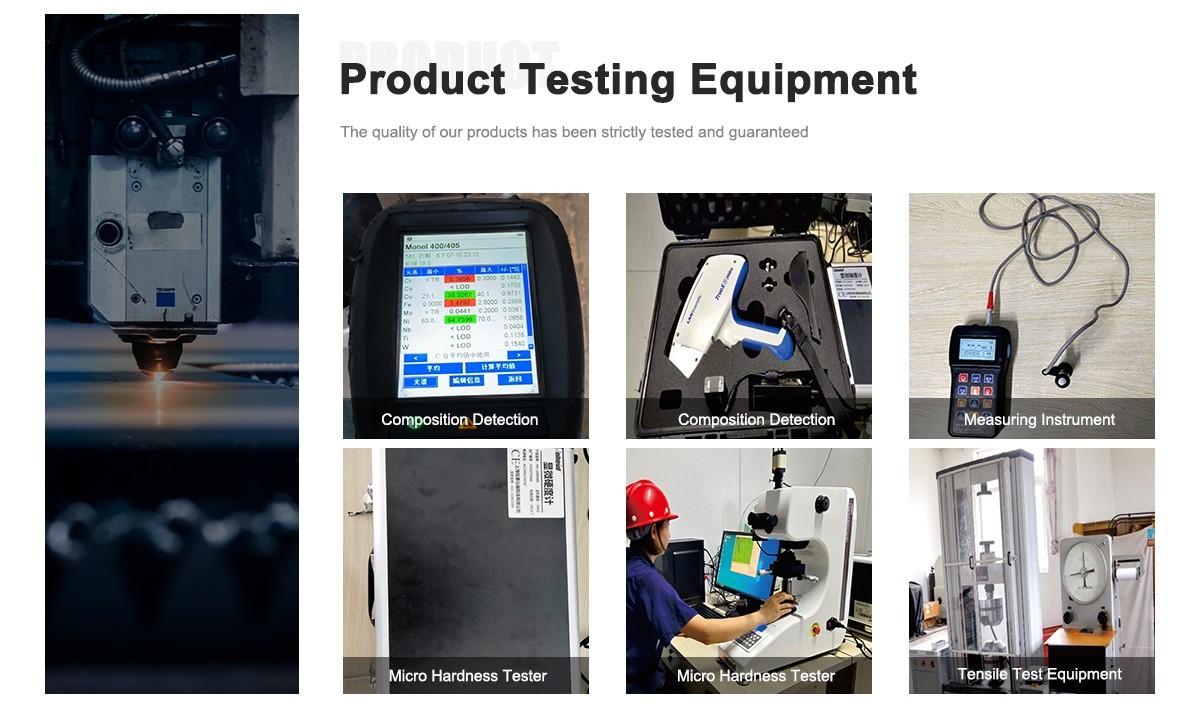

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is 1Cr13Al4 FeCrAl heating wire made of?

It is made of an iron-chromium-aluminum alloy with controlled amounts of chromium and aluminum for high resistance and oxidation stability.What is the main application of this heating wire?

It is mainly used in electric heaters, home appliances, and industrial heating elements.What temperature range can 1Cr13Al4 FeCrAl heating wire withstand?

It can operate reliably at temperatures up to around 1250°C depending on the design and environment.How does it compare to nickel-chromium heating wire?

FeCrAl wire has higher maximum operating temperature, better oxidation resistance, and longer service life in certain applications.Is it suitable for continuous heating applications?

Yes, it is highly stable and can be used in continuous operation with low creep at high temperatures.What industries commonly use FeCrAl heating wire?

Appliance manufacturing, metallurgy, ceramics, glass processing, and industrial furnaces.Can it be customized in size and form?

Yes, it is available in different diameters, coils, spools, and cut lengths depending on customer needs.Why choose DLX for FeCrAl heating wire?

Because DLX provides consistent quality, strict tolerance control, competitive pricing, and reliable global supply.