Household appliances like electric ovens, toasters, water heaters, and small-scale heating systems require wires that are both heat-resistant and corrosion-resistant. The 1Cr13Al4 FeCrAl Wire delivers exactly that, providing stable performance, long service life, and reliable heating efficiency. DLX designs this wire specifically for the unique requirements of household appliances, ensuring consistent temperature control, safety, and energy efficiency.

For more details, pls directly contact us

The 1Cr13Al4 FeCrAl Wire is an iron-chromium-aluminum alloy engineered for corrosion resistance and thermal stability. Chromium, at 13%, forms a protective oxide layer that prevents oxidation and corrosion even under high humidity or oxidizing conditions common in household appliances. Aluminum, at 4%, enhances the oxide layer’s stability and improves the wire’s structural integrity under high-temperature cycling. Iron serves as the core structural material, providing strength, durability, and consistent electrical conductivity. The combination ensures the wire performs reliably in heating elements exposed to both heat and moisture.

Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr23Al5 | 0Cr21Al4 | 0Cr27Al7Mo2 | ||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

This wire is designed primarily for household appliance heating elements. Applications include electric ovens, toasters, coffee machines, water heaters, and small electric heaters. Its corrosion-resistant properties make it ideal for devices that may encounter moisture or repeated thermal cycling. The 1Cr13Al4 wire can be used in coils, straight rods, or customized shapes depending on appliance design, offering flexibility and reliability in small-scale industrial heating solutions as well.

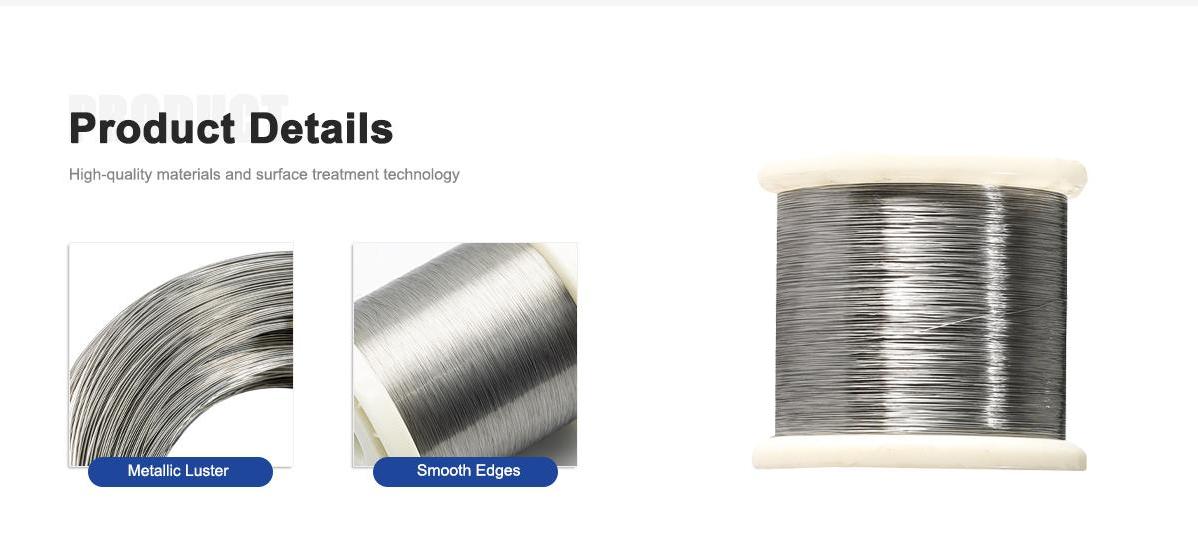

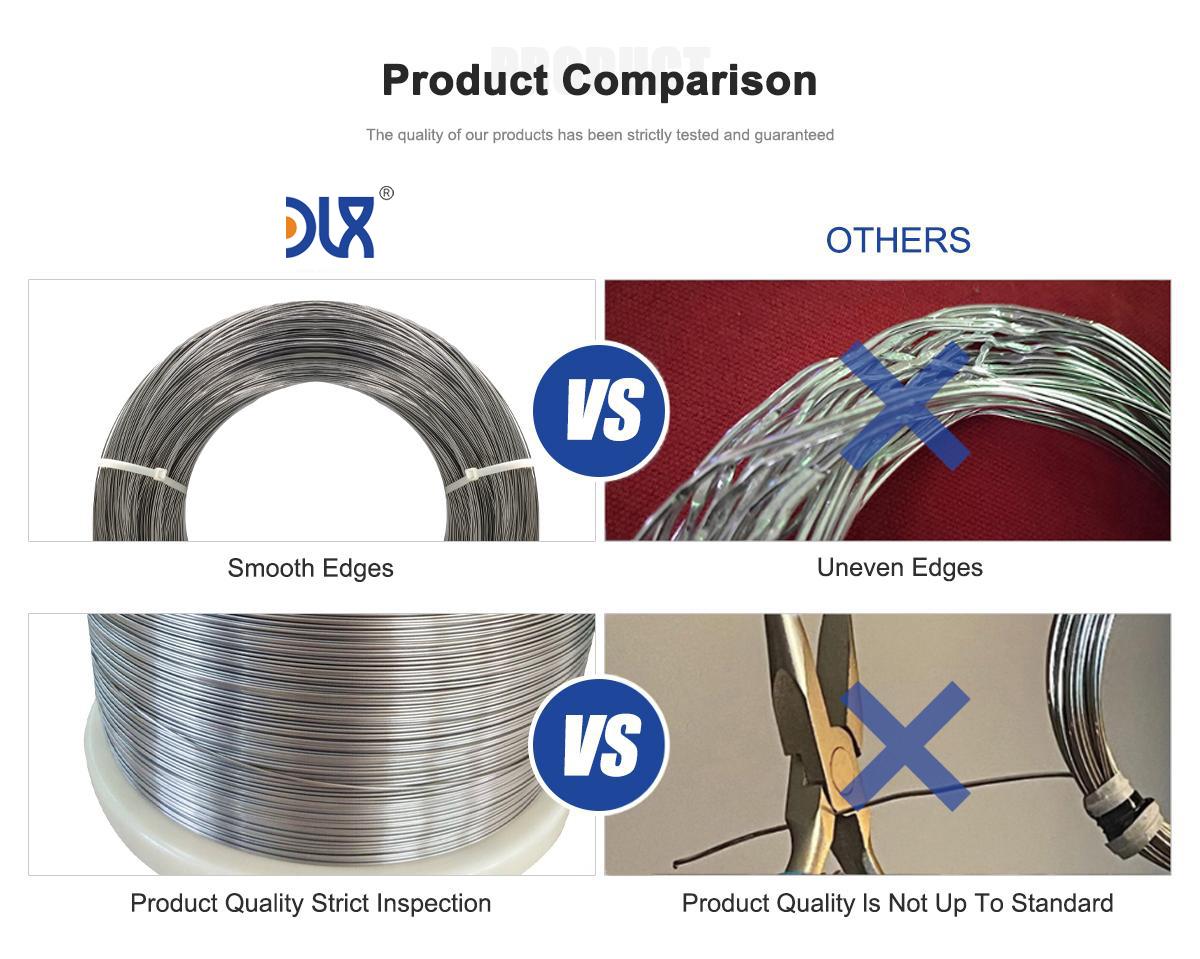

The 1Cr13Al4 FeCrAl Wire excels in corrosion resistance, high-temperature stability, and uniform electrical performance. Many standard wires used in household appliances degrade quickly due to oxidation or repeated thermal cycling. DLX’s wire maintains its structural integrity and consistent resistivity over long periods, reducing appliance failure rates and extending overall service life. The wire’s smooth and uniform surface minimizes scaling and ensures optimal heat transfer, providing reliable performance in various appliance designs.

Parameter Comparison Table:

| Property | 1Cr13Al4 FeCrAl Wire | Industry Average | Notes |

|---|---|---|---|

| Chromium (Cr) | 13% | 12-14% | Enhances corrosion resistance |

| Aluminum (Al) | 4% | 3.5-4.5% | Forms protective oxide layer |

| Iron (Fe) | Balance | Balance | Core structural element |

| Maximum Operating Temp | 1200°C | 1150°C | Stable heating for household applications |

| Electrical Resistivity | 1.2 Ω·mm²/m | 1.1-1.3 Ω·mm²/m | Ensures even heating performance |

| Corrosion Resistance | Excellent | Good | Suitable for moisture-prone environments |

| Form Availability | Coils, spools, custom | Coils & spools | Flexible supply options |

| Surface Finish | Smooth, uniform | Varies | Reduces scaling and enhances efficiency |

Durability is a critical factor in household appliances that are expected to operate safely over years of regular use. The 1Cr13Al4 wire withstands thermal expansion, moisture exposure, and repeated heating cycles without significant degradation. Its corrosion-resistant properties reduce the risk of wire oxidation, scaling, and potential appliance damage. DLX’s stringent quality control ensures each wire batch meets precise specifications, guaranteeing consistent performance and long-term reliability, ultimately enhancing appliance efficiency and consumer safety.

Industry Trends

Household appliances increasingly demand materials that balance performance, safety, and sustainability. Users expect devices that operate efficiently over years with minimal maintenance. Materials like 1Cr13Al4 FeCrAl wire meet these expectations by combining corrosion resistance with thermal stability and energy-efficient electrical performance. Sustainability trends also favor wires that reduce energy consumption and extend appliance lifespan, making DLX wires an ideal choice for modern, eco-conscious appliance manufacturers.

DLX differentiates itself in the household appliance wire market through precision, reliability, and customization:

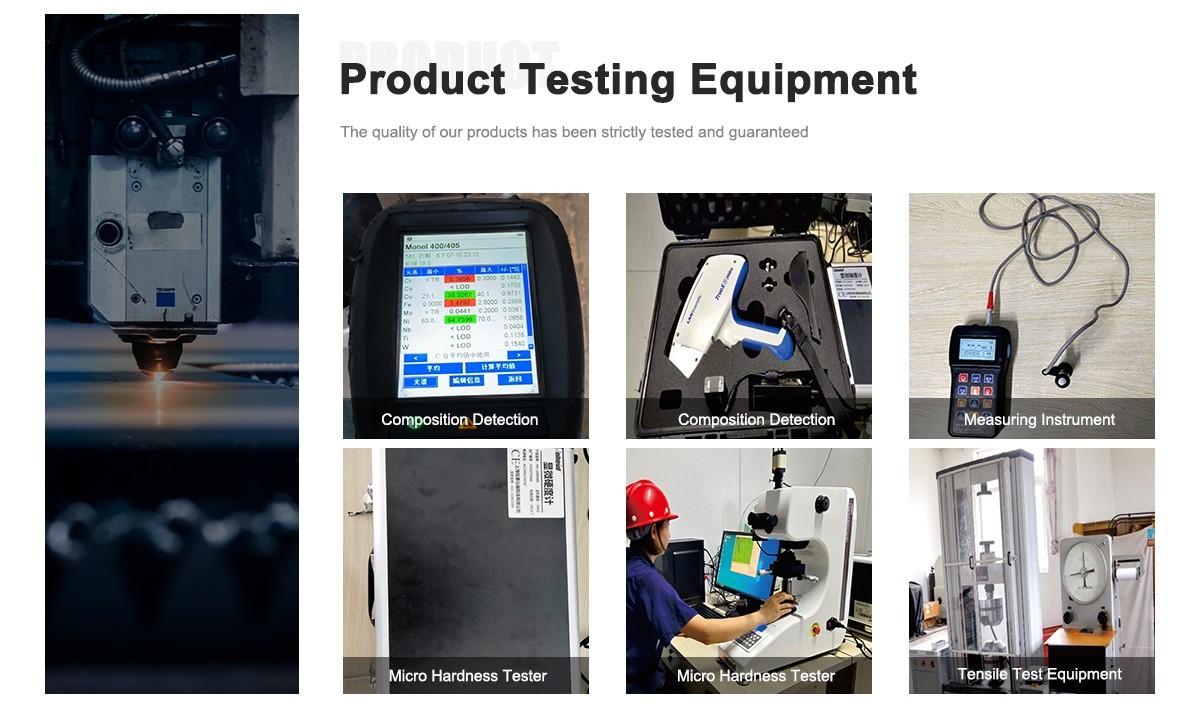

Quality Assurance: Every wire batch undergoes rigorous testing for chemical composition, electrical resistivity, and corrosion resistance.

Consistent Performance: Controlled manufacturing ensures uniform electrical properties and long-term corrosion resistance.

Versatile Supply Options: Available in coils, spools, or customized lengths to fit appliance-specific designs.

Customizable Solutions: Wire diameter, length, and surface finish can be tailored for individual appliance needs.

Technical Support: DLX provides guidance on installation, optimal operating conditions, and maintenance to maximize appliance performance and longevity.

Comparison with Standard Options

While other FeCrAl wires may offer similar compositions, DLX wires excel in corrosion resistance, uniformity, and long-term reliability. Standard alternatives often suffer from early oxidation, inconsistent heating, or scaling, affecting appliance performance. DLX’s precision manufacturing ensures predictable, reliable performance, reducing maintenance issues and improving overall appliance efficiency.

A household appliance manufacturer incorporated DLX 1Cr13Al4 wires into the heating elements of a popular electric water heater. Over two years of operation, the heating elements maintained uniform heating, showed minimal scaling, and required fewer replacements than previous standard wires. This led to reduced warranty claims, improved customer satisfaction, and lower operational costs, demonstrating the real-world benefits of using high-quality, corrosion-resistant FeCrAl wire in household appliances.

For household appliance manufacturers seeking durable, reliable, and corrosion-resistant heating solutions, the 1Cr13Al4 FeCrAl Wire from DLX offers a superior choice. Its combination of corrosion resistance, thermal stability, and long-term reliability ensures appliances operate safely and efficiently.

DLX’s focus on precision manufacturing, strict quality control, and customizable solutions makes the 1Cr13Al4 wire ideal for modern household appliances. By choosing DLX, manufacturers gain the confidence of delivering high-performing, energy-efficient, and long-lasting appliances to their customers, while also benefiting from reduced maintenance requirements and operational costs.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is 1Cr13Al4 FeCrAl Wire made of?

Iron, chromium, and aluminum.

What applications is this wire suitable for?

Household appliances, heating elements, and small-scale industrial heaters.

What is its maximum operating temperature?

Up to 1200°C continuous use.

How does it perform in corrosion resistance?

Excellent, designed to withstand moisture and oxidizing environments.

What forms does this wire come in?

Coils, spools, and custom lengths.

Is it suitable for intermittent and continuous heating?

Yes, designed for consistent performance in both scenarios.

Can DLX customize the wire for appliance-specific requirements?

Yes, diameter, length, and surface finish can be tailored.

How does this wire improve appliance efficiency?

Provides uniform heating, extends lifespan, and reduces energy consumption.