In industrial heating applications, selecting the right wire is crucial for efficiency, reliability, and long-term performance. The High-Resistivity 0Cr15Al5 FeCrAl Wire is designed to meet these demands, providing excellent thermal stability, oxidation resistance, and energy efficiency. DLX focuses on engineering wires that deliver consistent performance across a range of high-temperature industrial environments, ensuring long-lasting operational reliability.

For more details, pls directly contact us

The 0Cr15Al5 FeCrAl Wire is an iron-chromium-aluminum alloy engineered for high-resistivity applications. Chromium, at 15%, creates a strong oxide layer that protects the wire against oxidation and scaling, even under extended high-temperature exposure. Aluminum, at 5%, enhances this protective layer, increasing durability and maintaining structural integrity. Iron acts as the base material, offering mechanical strength and stability. The high resistivity of this wire ensures that it efficiently converts electrical energy into heat, making it ideal for precision industrial heating systems.

Alloy Nomenclature Performance | 0Cr25Al5 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

This wire is widely used in industrial furnaces, electrical resistance heating elements, and other high-temperature equipment. Its high-resistivity properties make it particularly suitable for applications requiring precise temperature control. The 0Cr15Al5 wire performs reliably under both continuous and intermittent heating cycles, making it a versatile solution for a variety of industrial processes. It can serve as the primary heating element, or as a supplementary component in complex furnace assemblies.

Performance Advantages

The High-Resistivity 0Cr15Al5 wire provides superior oxidation resistance and stable electrical performance. Many standard FeCrAl wires degrade quickly when exposed to high temperatures, leading to uneven heating and frequent replacements. DLX’s wire maintains uniform heating characteristics over long operational periods, reducing maintenance needs and improving process efficiency. Its high electrical resistivity ensures that energy is effectively converted into heat, providing consistent temperature distribution across the heating system.

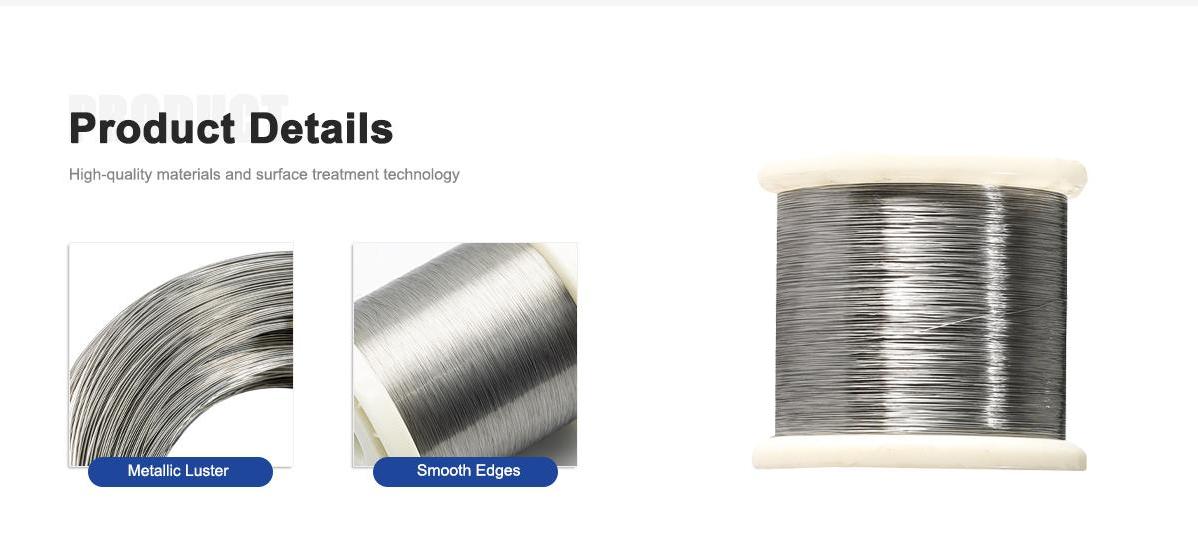

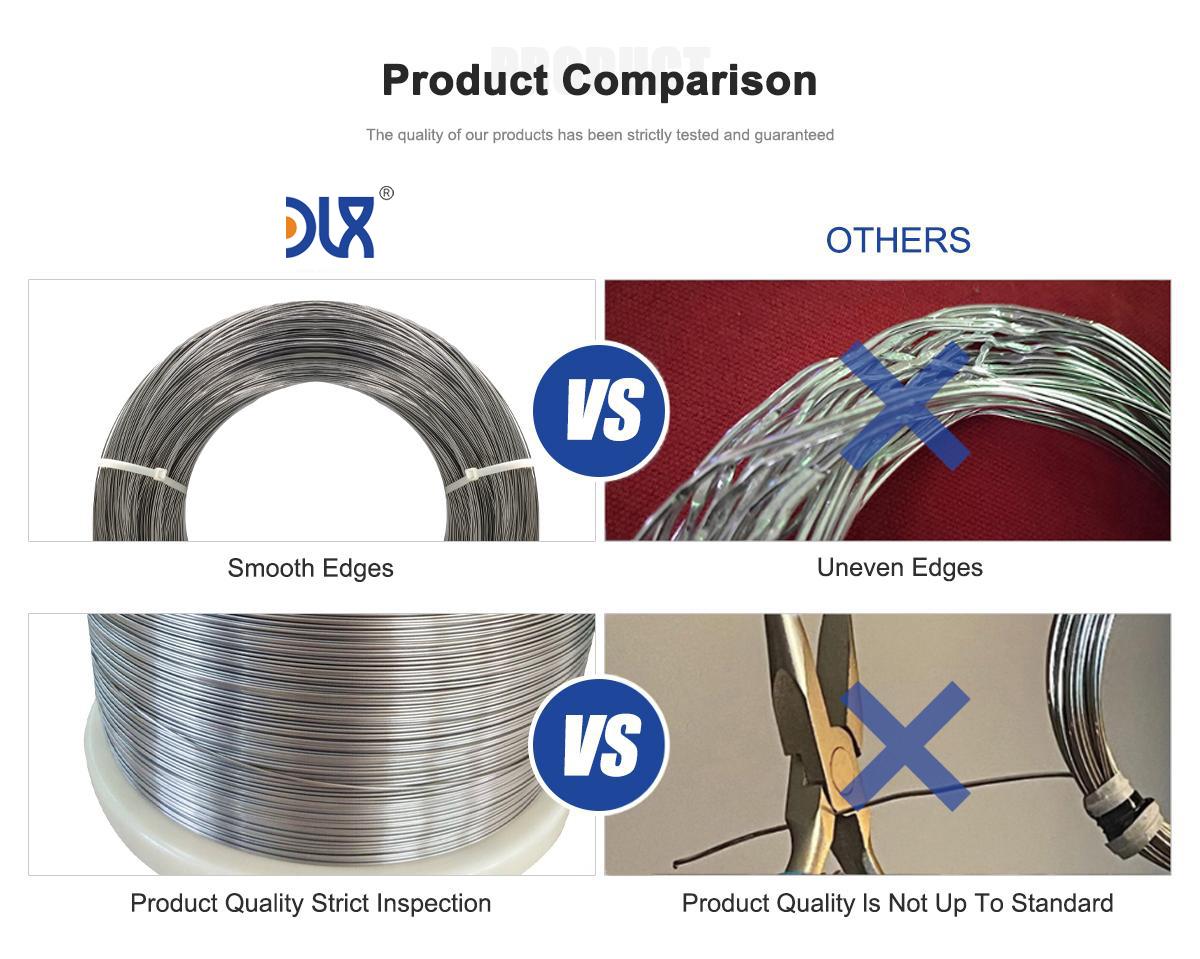

Durability is a critical factor in industrial heating applications. The 0Cr15Al5 FeCrAl wire offers exceptional long-term stability, resisting scaling, oxidation, and deformation under high-temperature conditions. The smooth, uniform surface finish reduces the formation of oxide layers that could impair heating efficiency. DLX’s strict quality control ensures that each batch meets exact chemical and mechanical specifications, guaranteeing predictable performance and extended service life. This reliability minimizes downtime and operational costs, which is essential for high-performance industrial environments.

Parameter Comparison Table:

| Property | 0Cr15Al5 FeCrAl Wire | Industry Average | Notes |

|---|---|---|---|

| Chromium (Cr) | 15% | 14-16% | Provides oxidation resistance |

| Aluminum (Al) | 5% | 4-5% | Forms protective oxide layer |

| Iron (Fe) | Balance | Balance | Core structural element |

| Maximum Operating Temp | 1300°C | 1250°C | Stable high-temp performance |

| Electrical Resistivity | High (1.5-1.6 Ω·mm²/m) | 1.3-1.5 Ω·mm²/m | Enables efficient heating |

| Oxidation Resistance | Excellent | Good | Extended service life in harsh conditions |

| Form Availability | Coils, spools, custom | Coils & spools | DLX offers flexible options |

| Surface Finish | Smooth, uniform | Varies | Reduces scaling and improves heat transfer |

The industrial heating sector is increasingly focused on energy efficiency, precision, and sustainability. Materials that maintain performance under high temperatures while minimizing energy loss are highly sought after. High-resistivity FeCrAl wires, such as 0Cr15Al5, meet these criteria by offering stable performance, long life, and minimal maintenance requirements. Sustainability goals in modern industry favor materials that reduce waste, lower energy consumption, and extend equipment lifespan—exactly the benefits provided by DLX’s high-resistivity FeCrAl wire.

DLX Company Advantages

DLX stands out in the FeCrAl wire market for quality, precision, and customer-focused solutions:

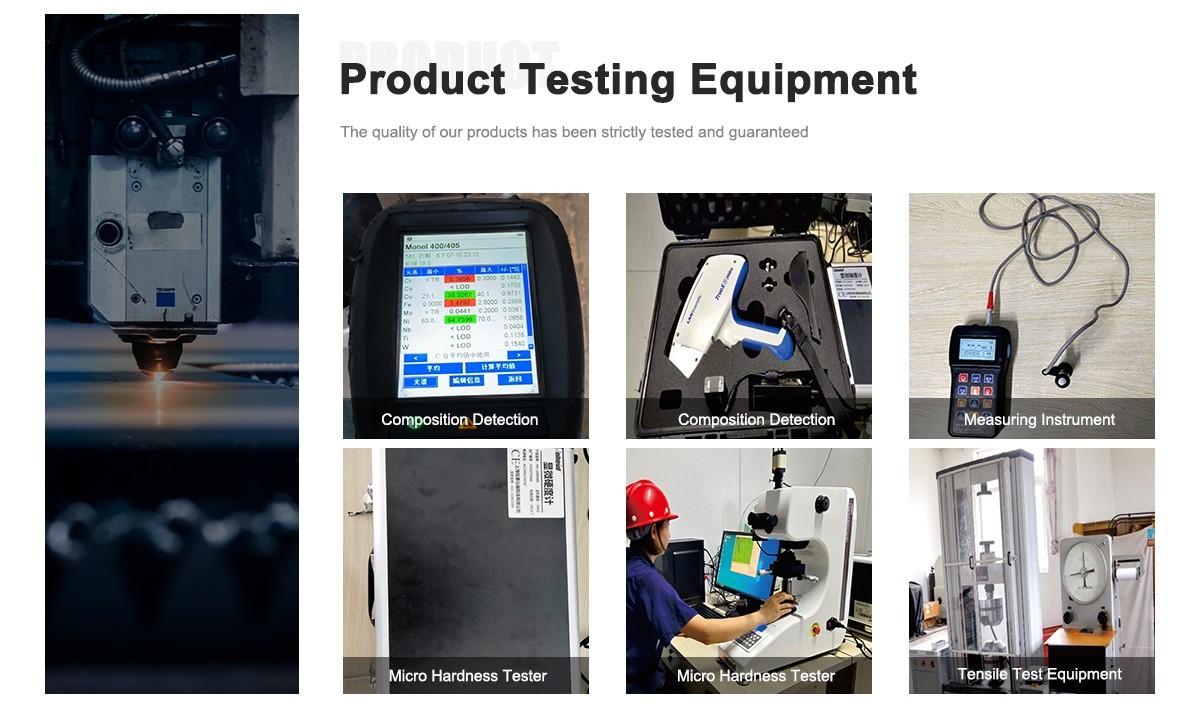

Rigorous Quality Assurance: Each wire is tested for chemical composition, resistivity, and surface uniformity.

Consistent Performance: Controlled manufacturing processes maintain stable resistivity and oxidation resistance.

Versatile Supply Options: Available in coils, spools, and custom lengths for diverse industrial requirements.

Customizable Solutions: Diameter, length, and surface finish can be tailored to meet client-specific needs.

Technical Support: DLX provides guidance on installation, optimal usage, and maintenance to maximize efficiency and lifespan.

While many FeCrAl wires offer similar chemical compositions, DLX wires provide superior resistivity, oxidation resistance, and surface uniformity. Standard alternatives may experience premature degradation, uneven heating, or scaling, impacting operational reliability. DLX’s precision manufacturing ensures predictable, consistent performance, reducing operational risks and improving furnace efficiency.

An industrial furnace manufacturer implemented DLX 0Cr15Al5 high-resistivity wire for precision heating elements in a batch-processing furnace operating at 1250°C. Over one year of continuous use, the wires maintained consistent heating performance, showed minimal scaling, and required fewer replacements compared to standard wires. This resulted in reduced energy consumption, lower maintenance costs, and improved overall process efficiency, illustrating the practical benefits of using high-quality FeCrAl wire.

For industrial operators seeking reliable, energy-efficient heating solutions, the High-Resistivity 0Cr15Al5 FeCrAl Wire from DLX is an excellent choice. Its combination of high resistivity, oxidation resistance, and long-term stability makes it ideal for industrial furnaces, electrical heating systems, and high-temperature processing equipment.

DLX’s precision engineering, strict quality control, and flexible manufacturing ensure that the 0Cr15Al5 wire delivers consistent, long-lasting performance. By selecting DLX, industrial operators gain improved operational efficiency, reduced maintenance costs, and reliable high-temperature performance, making this wire a critical component for modern industrial heating solutions.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is 0Cr15Al5 FeCrAl Wire made of?

Iron, chromium, and aluminum.

What applications is this wire suitable for?

Industrial heating, electrical resistance elements, and high-temperature furnaces.

What is its maximum operating temperature?

Up to 1300°C continuous use.

How does it perform in oxidation resistance?

Excellent, even under prolonged high-temperature exposure.

What forms does this wire come in?

Coils, spools, and custom lengths.

Is it suitable for continuous and intermittent heating?

Yes, designed for consistent performance in both scenarios.

Can DLX customize the wire for specific requirements?

Yes, diameter, length, and surface finish can be tailored.

How does this wire improve operational efficiency?

Provides uniform heating, reduces maintenance, and extends element lifespan.