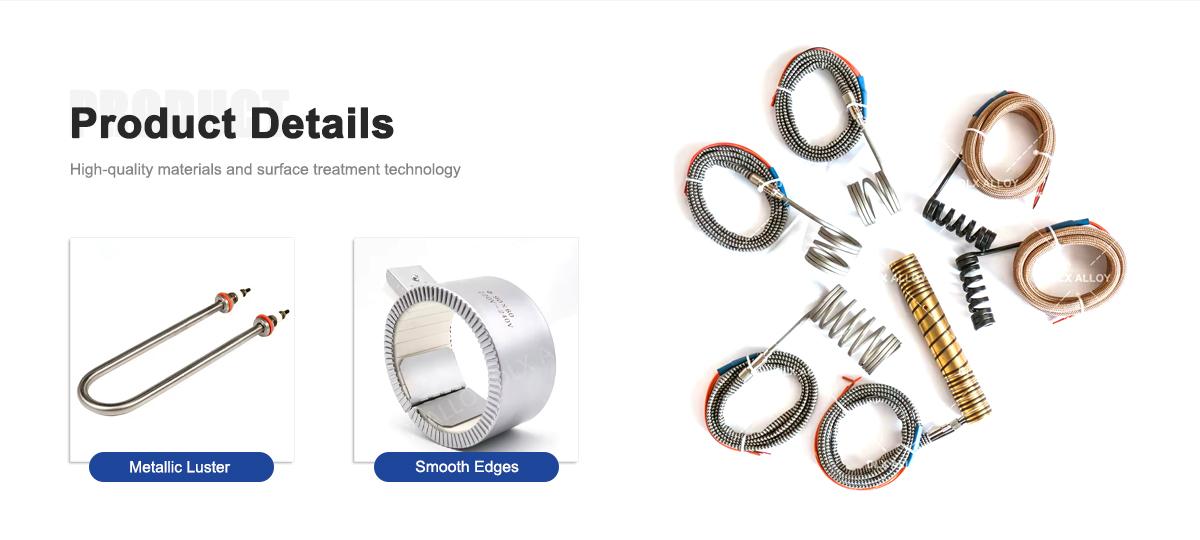

Our cartridge heaters are designed to deliver top performance for industrial heating needs. Built with a tough stainless steel sheath and powered by nichrome wire, these heaters use magnesium oxide insulation to spread heat evenly. With options like 200W and 250W at AC 220V and 50Hz, they’re perfect for heating molds, dies, and platens. The compact design ensures reliable and efficient operation every time.

Industry Analysis

As of July 2025, the heating element market is growing fast, with a big push toward energy efficiency and smart tech. Industries want heaters that save power and integrate with modern controls, and we’re leading the charge with our innovative designs. Sustainability is also key, and our durable materials help meet this demand head-on.

Applications

These heaters are a go-to in plastics processing for precise mold heating, in packaging for sealing lines, and in medical manufacturing for sterilization tasks. Their versatility makes them essential across these sectors, keeping production smooth and efficient.

Company Comparison

We stand out with our cartridge heaters by offering full customization to fit your specific needs, from power to size. Our stainless steel build and expert design mean you get a heater that lasts longer and performs better, cutting your costs over time. Plus, our dedicated team provides fast, tailored support, giving you an edge over the competition.

Parameter | Our Cartridge Heater | Competitor Standard |

|---|---|---|

Power Rating | 200W / 250W | 150W / 200W |

Voltage | AC 220V, 50Hz | AC 220V, 50Hz |

Material | Stainless Steel, Nichrome | Stainless Steel |

Insulation | Magnesium Oxide | Ceramic |

Customization | Fully Customizable | Limited Options |

Heat Distribution | Uniform | Moderate |

Durability | High | Average |

Support | In-house Expertise | Standard Support |

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is this heating element used for?

It is a cartridge heater, perfect for heating molds, dies, and platens in industrial settings.What materials are used in this heating element?

It features a stainless steel sheath with nichrome wire and magnesium oxide insulation.What are the power ratings of this heater?

Available in 200W and 250W, operating at AC 220V with 50Hz.In which industries is this heater applied?

Commonly used in plastics processing, packaging, and medical device manufacturing.How does the design benefit its performance?

The cylindrical design ensures uniform heating and efficient heat transfer.What are the current industry trends for this type of heater?

There’s a rise in demand for energy-efficient and customizable heating solutions.How durable is this heating element?

The stainless steel construction offers excellent durability and resistance to wear.Can it be customized for specific needs?

Yes, we provide options for custom sizes, wattages, and configurations.