PTFE insulated flexible heating tape is made using Nickel-Chromium (NiCr 80/20) or FeCrAl alloy resistance wires as the heating core, surrounded by PTFE (Polytetrafluoroethylene) insulation. PTFE, known for its chemical inertness, non-stick surface, and excellent temperature resistance, offers superior protection against moisture, acids, alkalis, and corrosive gases. This makes it ideal for industrial environments where reliability under harsh conditions is essential. The heating tape is flexible, durable, and suitable for continuous operation up to 260°C, while providing short-term exposure resistance up to 300°C.

Applications

Chemical and petrochemical plants

Food and beverage processing equipment

Pharmaceutical and biotechnology systems

Marine and offshore installations

Moist industrial environments

De-icing and anti-condensation systems

For more details, pls directly contact us.

The demand for PTFE insulated heating tapes is rising due to the growth of corrosion-prone and moisture-exposed industries. Companies are increasingly seeking maintenance-free, safe, and flexible heating solutions that can operate reliably in chemical, marine, or humid environments. The industry trend is shifting toward high-durability heating systems with longer lifespans and reduced energy waste. DLX’s PTFE insulated heating tapes align with these needs by combining material innovation and industrial-grade performance.

Comparison Table

| Parameter | PTFE Insulated Heating Tape | Silicone Rubber Heating Tape | Glass Fiber Braided Heating Tape |

|---|---|---|---|

| Max Temperature | 260°C continuous / 300°C peak | 200°C | 450°C |

| Chemical Resistance | Excellent | Good | Excellent |

| Waterproof Performance | Excellent | Excellent | Limited |

| Flexibility | Very High | High | Moderate |

| Corrosion Resistance | Outstanding | Good | Good |

| Electrical Insulation | Excellent | Excellent | High |

| Cost Level | Medium-High | Medium | Medium |

| Typical Use | Moist or chemical environments | Outdoor heating | Lab and industrial heating |

Article: PTFE Insulated Flexible Heating Tape for Corrosive and Moist Environments

In industries where corrosion, humidity, and chemical exposure are constant challenges, finding a reliable heating solution is critical. DLX’s PTFE Insulated Flexible Heating Tape was developed to meet exactly those needs — combining advanced materials with precision engineering to deliver a high-performance, durable heating solution for extreme conditions.

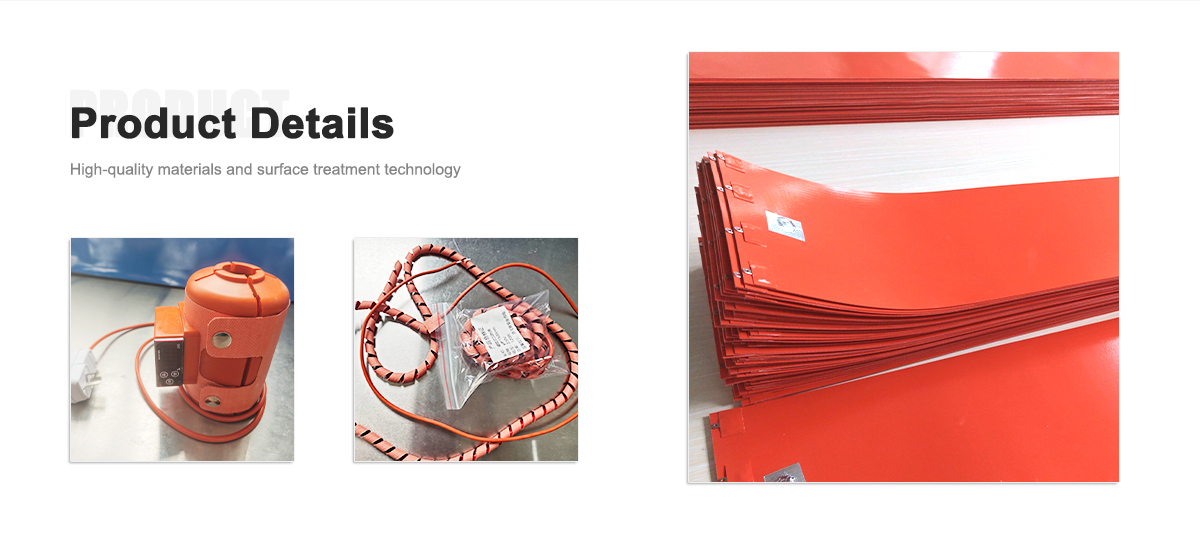

DLX’s manufacturing advantage

DLX sets itself apart through complete in-house control — from alloy melting and wire drawing to final assembly and testing. This ensures that every meter of PTFE heating tape meets strict performance standards.

We use high-precision extrusion equipment to apply PTFE uniformly, achieving consistent insulation thickness and preventing weak points. Our products undergo high-voltage, insulation resistance, and temperature endurance testing before delivery, ensuring they meet or exceed international safety and performance standards.

Applications across industries

Chemical Processing: Ideal for corrosive gas pipelines, chemical reactors, and fluid storage systems.

Marine and Offshore: Used for frost protection and anti-condensation in ship pipelines and valves.

Food and Beverage: Maintains consistent temperatures in hygienic and wet environments.

Pharmaceutical: Prevents crystallization and maintains temperature control in production systems.

General Industrial: Suitable for process heating, tank warming, and environmental conditioning.

DLX vs conventional heating tapes

Traditional silicone rubber or fiberglass tapes, while effective, have limitations in highly corrosive or wet settings. PTFE insulation solves this issue by providing complete waterproofing and chemical resistance, ensuring long-term operation even under constant exposure.

DLX’s PTFE heating tapes combine high flexibility, uniform heat distribution, and exceptional safety, making them the first choice for engineers who demand reliability in every condition. Our advantage lies in our ability to customize voltage, width, watt density, and length — offering tailored solutions for specific applications.

Why industries trust DLX

Clients around the world rely on DLX heating tapes because of our commitment to material quality, engineering precision, and responsive service. Each tape is designed with the end-user in mind — easy to install, efficient in energy use, and robust against environmental challenges.

By combining our decades of resistance heating expertise with modern PTFE technology, we create heating solutions that extend system lifespan, reduce downtime, and maintain stable operation even in the harshest industrial environments.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is a PTFE insulated heating tape used for?

It’s mainly used for heating applications in corrosive, moist, or chemically active environments, such as pipelines, tanks, and process equipment.

2. How high can PTFE insulated heating tape operate?

DLX’s PTFE heating tapes operate continuously up to 260°C, with short-term peaks up to 300°C.

3. Can it resist acids and alkalis?

Yes. PTFE insulation is chemically inert, offering excellent resistance to acids, bases, solvents, and industrial gases.

4. Is it waterproof?

Absolutely. The PTFE layer provides complete moisture protection, making it ideal for damp or outdoor installations.

5. What voltages are available?

DLX customizes the voltage range, including 110V, 220V, or user-specified requirements for different heating systems.

6. Can it be wrapped around small-diameter pipes?

Yes, it’s highly flexible, allowing installation on pipes, valves, and irregular surfaces.

7. How long does it last?

With proper installation, DLX PTFE heating tapes can last 5–10 years, depending on the working environment and temperature cycle.

8. Why choose DLX’s PTFE heating tapes?

DLX ensures superior wire uniformity, insulation consistency, and strict quality control, delivering heating tapes that perform under the harshest industrial conditions.