Silicone rubber insulated heating tapes are typically made from resistance heating wires such as Nichrome (NiCr 80/20) or FeCrAl (Iron-Chromium-Aluminum), embedded within layers of high-quality silicone rubber insulation. This structure provides exceptional flexibility, weather resistance, and long service life. The silicone rubber outer sheath also offers protection against moisture, chemicals, and mechanical damage, making it ideal for both indoor and outdoor use.

Pipeline freeze protection

Temperature maintenance of process equipment

Industrial tanks and vessels heating

Laboratory and pharmaceutical equipment

Food processing and beverage industries

HVAC systems and environmental chambers

For more details, pls directly contact us.

The industrial heating tape market is expanding rapidly due to growing demand in oil & gas, chemical, and energy industries. The trend is moving toward flexible, energy-efficient, and smart heating solutions that can be easily installed and controlled. With stricter energy efficiency regulations, more manufacturers are adopting advanced silicone heating technologies that minimize heat loss and maintenance costs

| Parameter | Silicone Rubber Insulated Heating Tape | PVC Heating Tape | Glass Fiber Heating Cable |

|---|---|---|---|

| Max Temperature | Up to 200°C | Up to 90°C | Up to 400°C |

| Flexibility | Excellent | Moderate | Good |

| Chemical Resistance | High | Medium | High |

| Water Resistance | Excellent | Poor | Moderate |

| Durability | Long-lasting | Average | Long-lasting |

| Installation | Easy | Easy | Moderate |

| Cost | Medium | Low | High |

| Typical Application | Industrial processes | Domestic heating | High-temp furnaces |

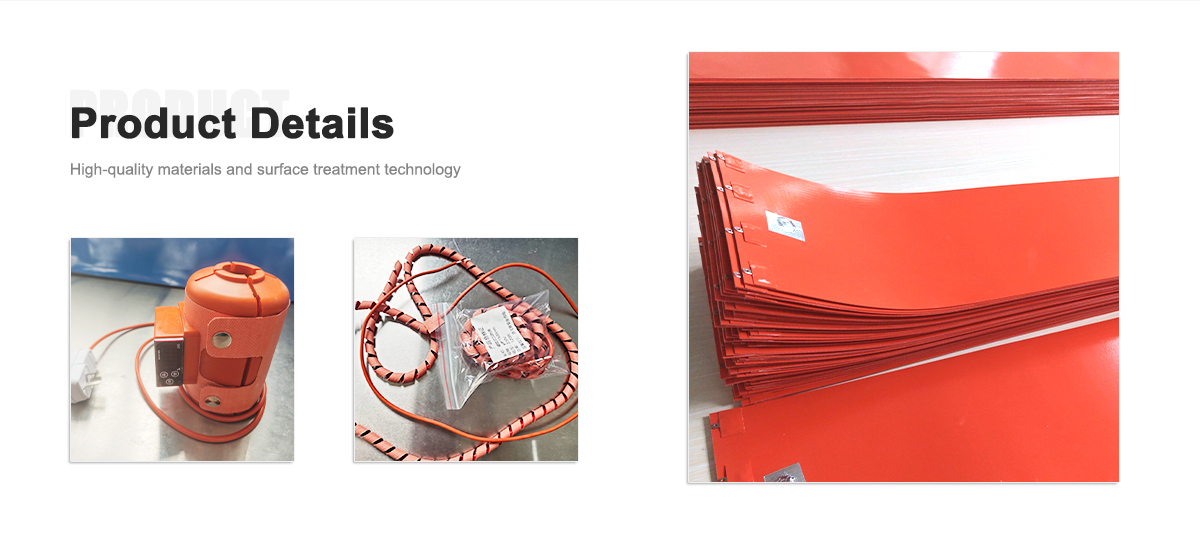

Article: Silicone Rubber Insulated Heating Tape for Industrial Applications

At DLX Alloy, we specialize in providing advanced heating solutions for industrial environments that demand both flexibility and reliability. Our Silicone Rubber Insulated Heating Tape is engineered for continuous performance under challenging conditions such as chemical exposure, outdoor weather, or temperature fluctuations.

This heating tape combines the proven durability of silicone rubber with the efficiency of resistance heating alloys like NiCr (Nickel-Chromium) and FeCrAl (Iron-Chromium-Aluminum). These materials offer consistent electrical resistance and excellent oxidation resistance even at elevated temperatures.

From chemical plants to food processing facilities, our silicone heating tapes ensure steady and controlled heating across pipes, valves, tanks, and other industrial equipment. Unlike rigid heaters or high-maintenance systems, silicone tapes can be wrapped around irregular shapes, offering efficient heat transfer and easy installation.

Why silicone rubber insulation matters

Silicone rubber provides excellent flexibility, making the tape suitable for curved or complex surfaces. It’s also resistant to chemicals, oil, and moisture—ensuring that the tape performs even in harsh industrial environments. Additionally, the silicone layer acts as an electrical insulator, enhancing operational safety during use.

Industry analysis and trend insight

As industries shift toward smarter and more sustainable heating systems, silicone rubber heating tapes are gaining popularity due to their energy efficiency and versatility. Compared to older rigid heating systems, flexible tapes consume less energy and provide precise temperature control, reducing waste heat and operational costs.

The integration of temperature sensors and control modules also supports automation, aligning with modern industry 4.0 standards. In this evolving landscape, companies are demanding heating solutions that combine long service life, minimal downtime, and customizability — all of which DLX offers.

At DLX, every silicone rubber heating tape is produced in-house, allowing us to control every detail from material selection to quality inspection. Our resistance wires come from our own alloy melting and drawing facilities, ensuring consistent composition and stability. We also offer tailored voltage, power density, and length according to specific client requirements.

Compared to other manufacturers that rely on outsourced wires or silicone sheaths, DLX’s integrated production process guarantees superior thermal efficiency and mechanical reliability. Each batch undergoes testing for insulation resistance, dielectric strength, and uniform heating performance.

Applications across industries

Chemical processing: Prevent condensation or freezing in acid and solvent lines.

Food & beverage: Maintain fluidity of syrups, oils, and dairy products.

Power plants: Keep process pipes operational during cold seasons.

Pharmaceutical: Control temperature during mixing or storage processes.

HVAC and environmental testing: Regulate heating for controlled environments.

Why customers choose DLX

Clients trust DLX because we deliver custom-engineered heating tapes that match industrial-grade standards for safety and performance. We provide technical support for installation, power calculation, and temperature design. Our products are widely recognized for their consistent heat output and long service life.

With rising emphasis on energy conservation and process optimization, the global demand for silicone rubber heating tapes is expected to rise steadily. DLX continues to invest in R&D for improving insulation technology and integrating smart control systems. This ensures our customers stay ahead of industry trends with reliable, adaptable, and efficient heating solutions.

At DLX, we don’t just supply heating tapes — we deliver performance, reliability, and efficiency that help industries operate without interruption, even in the toughest environments.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is silicone rubber heating tape used for?

It’s designed for maintaining or raising temperatures in pipelines, tanks, or industrial surfaces where consistent heat is required.

2. How high can the temperature go?

Most silicone rubber insulated tapes can operate continuously up to 200°C, depending on the resistance wire and design.

3. Is it waterproof?

Yes, the silicone rubber outer layer is moisture-resistant, suitable for humid or outdoor conditions.

4. Can it be used on stainless steel pipes?

Absolutely. Silicone heating tapes are compatible with metals like stainless steel, copper, and aluminum.

5. What voltages are available?

Common models come in 110V, 220V, or custom voltages as required for industrial systems.

6. How do you install silicone rubber heating tape?

It’s usually wrapped around the pipe or tank and secured with high-temperature tape or straps. No special tools are required.

7. What’s the lifespan of the heating tape?

With proper use, the service life typically exceeds 5 years due to the robust silicone insulation.

8. Why choose DLX’s silicone heating tape?

DLX offers custom sizes, superior heat uniformity, and in-house manufacturing with strict quality control, ensuring reliable performance for industrial environments.