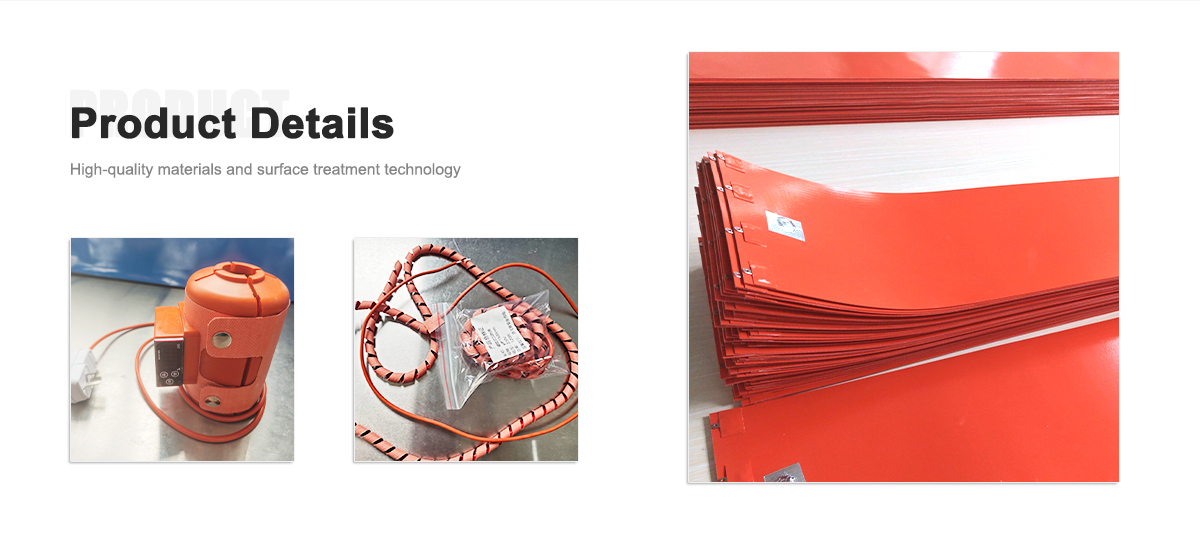

High temperature electric heating tapes are built from premium resistance alloys such as Nichrome (NiCr 80/20) and Iron-Chromium-Aluminum (FeCrAl 0Cr23Al5 ). These alloys are selected for their exceptional resistance stability, oxidation resistance, and consistent performance under elevated temperatures. The insulation layer often includes fiberglass, silicone rubber, or fluoropolymer (PTFE/FEP) depending on the operating conditions. Some models are reinforced with stainless steel braids or mineral insulation for added mechanical strength and chemical resistance. This composition allows the heating tape to function efficiently in environments reaching up to 600°C, providing durable and safe heat transfer for industrial equipment and tanks.

For more details, pls directly contact us.

High temperature electric heating tapes are versatile and can be used across multiple industries:

Process equipment heating in chemical and petrochemical plants

Tank and vessel temperature maintenance for viscous or temperature-sensitive materials

Oil and gas pipelines to prevent paraffin buildup

Pharmaceutical and food processing for controlled heating of fluids

Aerospace and laboratory systems requiring precision temperature control

Power plants and refineries for frost protection and fluid flow assurance

Industry Trends

The global heating systems market is rapidly moving toward energy-efficient, durable, and flexible heating solutions. With increasing demand for process automation and temperature accuracy, flexible heating tapes have become a preferred choice for both new installations and equipment upgrades. In industrial environments, high temperature heating tapes are replacing traditional rigid heaters due to their ease of installation, even heat distribution, and compatibility with modern temperature control systems. Additionally, industries are emphasizing sustainability and safety, pushing for materials that consume less power and maintain longer lifespans.

DLX Company Perspective

At DLX, we engineer high temperature electric heating tapes that meet the highest industrial standards for performance, durability, and adaptability. Our products are manufactured using premium-grade resistance alloys and advanced insulation technologies, ensuring consistent temperature control under demanding conditions. Compared to conventional heating cables or bands, DLX tapes deliver more uniform heat transfer and superior flexibility, allowing them to wrap seamlessly around tanks, pipes, and process equipment.

Each DLX heating tape undergoes strict quality testing for insulation integrity, resistance stability, and temperature tolerance. We also offer custom wattage, voltage, and length options, ensuring perfect compatibility with client systems. From chemical plants to refineries, our heating tapes have proven their reliability in maintaining process efficiency and safety.

Comparison Table

| Property | DLX High Temp Heating Tape | Standard PVC Heating Cable | Mineral Insulated Cable |

|---|---|---|---|

| Heating Element | NiCr 80/20 or FeCrAl 0Cr23Al5 | Copper Alloy Wire | NiCr or CuNi Wire |

| Insulation Material | Fiberglass / Silicone / PTFE | PVC | Magnesium Oxide + Metal Sheath |

| Max Operating Temperature (°C) | Up to 600°C | Up to 90°C | Up to 800°C |

| Flexibility | Excellent | Moderate | Low |

| Weather & Chemical Resistance | High | Low | Excellent |

| Application Area | Tanks, Pipes, Process Lines | Indoor Heating | Industrial High Temp Use |

| Lifespan | 8–10 Years | 2–3 Years | 10+ Years |

| Customization Options | Voltage, Wattage, Length | Limited | Limited |

Article: Reliable Heating for Modern Industrial Systems

In today’s fast-paced industrial world, maintaining consistent process temperatures is critical for safety, efficiency, and product quality. DLX’s high temperature electric heating tapes are designed to deliver dependable heating performance in the most demanding environments, from petrochemical plants to food processing facilities.

These heating tapes are built using advanced resistance alloys such as NiCr 80/20 and FeCrAl 0Cr23Al5, known for their high melting points and excellent oxidation resistance. They generate uniform heat, even over long distances, while maintaining low energy loss. The insulation layers — made from fiberglass, silicone rubber, or PTFE — provide superior flexibility and protection against environmental stress.

Unlike traditional rigid heaters or cable systems, DLX’s heating tapes are incredibly versatile. Their flexible construction allows them to wrap tightly around complex equipment surfaces such as tanks, valves, or curved pipelines. This ensures maximum contact and uniform heat transfer, which is essential for processes involving viscous or temperature-sensitive materials.

In industries like oil and gas, these tapes play a vital role in preventing paraffin buildup or freezing inside pipelines, ensuring smooth flow and preventing costly downtime. In chemical processing, they maintain the viscosity of liquids, enabling stable reactions and efficient production. For food and pharmaceutical industries, precise heat control ensures product integrity and safety.

The industrial heating market is evolving rapidly, with growing demand for energy-efficient, high-performance systems. DLX responds to this trend by integrating material science innovations and modern manufacturing technology into every product. Our heating tapes are engineered to reduce power consumption while maintaining consistent output, offering a reliable balance between efficiency and performance.

DLX’s in-house testing and quality assurance procedures ensure that each heating tape meets strict electrical and thermal performance standards. We also provide custom engineering support, helping clients design heating systems that match their operational requirements. Whether for maintaining process temperatures or preventing frost, our products deliver reliability you can trust.

Another major advantage of DLX heating tapes is ease of installation. They are lightweight, flexible, and compatible with standard thermostats and temperature controllers. This allows operators to quickly deploy them in new systems or retrofit them to existing setups.

As industries move toward smarter and greener technologies, DLX continues to lead in providing heating solutions that align with sustainability goals. By improving heat transfer efficiency and extending product lifespan, our tapes contribute to lower operational costs and reduced environmental impact.

Ultimately, the success of any industrial process depends on reliable temperature control — and that’s exactly what DLX delivers. Our high temperature electric heating tapes combine durability, performance, and customization, helping businesses maintain optimal process conditions year-round.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is a high temperature electric heating tape?

It’s a flexible electric heater designed to maintain or raise the temperature of industrial equipment, tanks, or pipes operating in high-temperature environments.

2. What materials are used in DLX heating tapes?

DLX uses high-quality NiCr or FeCrAl resistance wires insulated with fiberglass, silicone, or PTFE for excellent heat resistance and electrical safety.

3. What temperature range can these tapes handle?

They can operate continuously up to 600°C, depending on the model and insulation type.

4. Can DLX heating tapes be used in outdoor or corrosive environments?

Yes, the insulation and braiding options make them resistant to moisture, UV, and chemicals, suitable for harsh industrial conditions.

5. How are these heating tapes installed?

They can be wrapped directly around pipes, tanks, or irregular surfaces and secured using heat-resistant tape or clamps.

6. What voltage options are available?

Standard options include 110V, 220V, and 240V, with custom voltages available for specialized systems.

7. How do they differ from conventional heating cables?

Heating tapes are more flexible and provide better surface contact, ensuring more efficient heat transfer on curved or uneven surfaces.

8. How long do DLX heating tapes last?

With proper installation and maintenance, they typically last 8 to 10 years even under high-temperature conditions.