Glass fiber braided heating tapes are made with a core resistance heating element — commonly Nickel-Chromium (NiCr 80/20) or FeCrAl alloy — encased in layers of braided glass fiber insulation. The glass fiber serves as a high-temperature resistant protective layer that ensures durability and electrical insulation, while the alloy wire provides uniform heating. These tapes can withstand temperatures up to 450°C, making them suitable for laboratory, research, and chemical applications where stable and controllable heat is required.

Laboratory heating and testing setups

Chemical process lines and glass reactors

Pipe tracing and vessel heating

Industrial drying systems

Pharmaceutical production equipment

Analytical and testing instruments

For more details, pls directly contact us.

The use of glass fiber braided heating tapes is expanding as industries prioritize precision heating and thermal stability. With the growth of research laboratories, biotechnology facilities, and chemical processing plants, there’s an increasing need for flexible heating systems that can deliver targeted heat while maintaining electrical safety. The shift toward energy-efficient and modular heating solutions is driving innovation in heating tapes, especially for scientific and industrial environments.

Comparison Table

| Parameter | Glass Fiber Braided Heating Tape | Silicone Rubber Heating Tape | Mica Insulated Heating Cable |

|---|---|---|---|

| Max Temperature | Up to 450°C | Up to 200°C | Up to 600°C |

| Flexibility | Moderate | High | Low |

| Chemical Resistance | Excellent | Good | Excellent |

| Water Resistance | Limited | Excellent | Limited |

| Durability | High | High | Very High |

| Installation | Easy | Easy | Moderate |

| Cost | Medium | Medium | High |

| Typical Use | Labs, Chemical Plants | General Industry | High-Temp Equipment |

Article: Glass Fiber Braided Heating Tape for Laboratory and Chemical Use

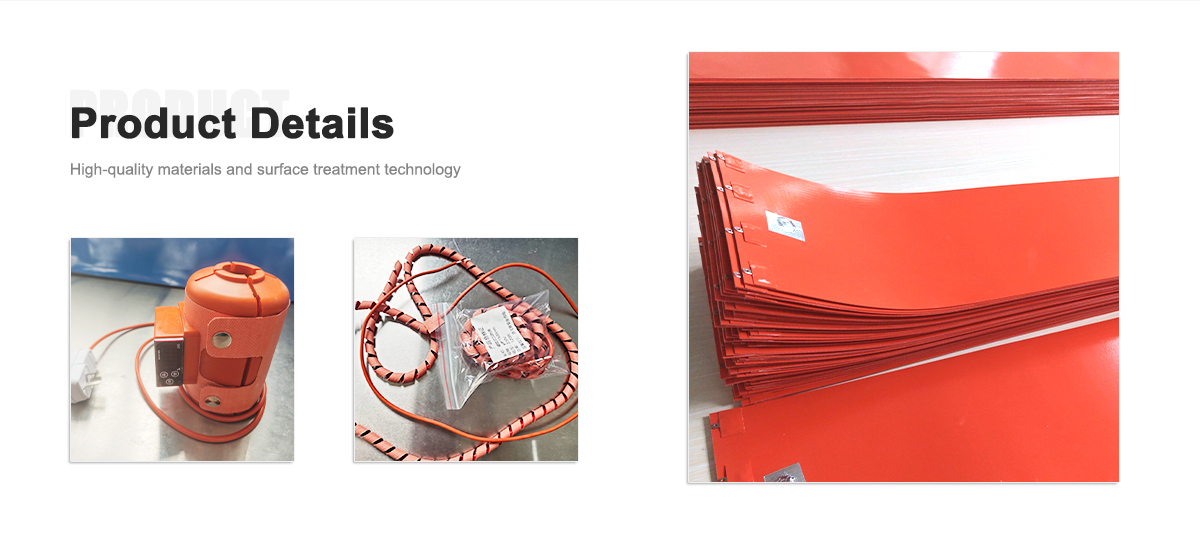

At DLX Alloy, we design and manufacture Glass Fiber Braided Heating Tapes that deliver precise and reliable heating for demanding laboratory and industrial environments. These tapes are built from high-grade resistance alloys combined with durable glass fiber insulation, offering both performance and protection for heat-sensitive processes.

Our product is engineered to maintain stable temperatures across equipment such as laboratory glassware, chemical reactors, pipelines, and distillation columns. Whether it’s for a small-scale experiment or an industrial pilot plant, DLX’s heating tapes provide consistent thermal output with superior safety and durability.

Material and construction excellence

Each heating tape starts with a carefully selected resistance wire — usually NiCr 80/20 or FeCrAl alloy — known for its stable resistivity and oxidation resistance. These wires are braided or spiraled within layers of glass fiber, which provides excellent electrical insulation and withstands continuous exposure to high temperatures.

Unlike plastic-insulated tapes, the glass fiber braided structure can operate at up to 450°C, making it ideal for high-temperature applications such as chemical synthesis, drying, or heat treatment. The braided sheath also provides mechanical strength, protecting the heating element from abrasion or chemical splashes.

The global demand for precision heating products has grown significantly across laboratory and chemical sectors. As industries adopt more automated and temperature-controlled systems, flexible heating solutions like DLX’s glass fiber tapes are becoming the preferred choice.

While traditional rigid heaters or electric mantles have limitations in coverage and efficiency, flexible heating tapes can conform to various equipment shapes, ensuring uniform heat transfer and reducing energy consumption. This adaptability aligns with modern laboratory needs where process flexibility and space efficiency are critical.

DLX’s manufacturing advantage

DLX stands out by maintaining complete control over the production chain — from melting and drawing alloy wires to assembling the final heating tape. This vertical integration allows us to customize every specification, ensuring our clients receive products tailored to their process parameters.

We apply strict testing standards, including insulation resistance, temperature uniformity, and thermal endurance tests, guaranteeing long-term reliability. Our heating tapes not only meet but often exceed industrial safety and performance requirements.

Laboratories and research institutions: Heating flasks, columns, and vessels for reactions and distillations.

Chemical and pharmaceutical plants: Maintaining consistent process temperatures in reaction lines and containers.

Industrial maintenance: Dehydration and drying of equipment during servicing or assembly.

Food and beverage production: Temperature control in ingredient processing and analysis.

Power generation and petrochemical: Heating of fluid lines in cold or controlled environments.

DLX vs traditional systems

Traditional heating mantles or plate heaters are often limited by shape, requiring specific vessel dimensions and offering less uniform heat. In contrast, DLX’s glass fiber braided heating tapes are modular, adaptable, and energy-efficient, capable of wrapping around irregular shapes without compromising safety or performance.

DLX’s tapes are also lighter, easier to install, and require minimal maintenance compared to conventional heating systems, reducing both operational cost and downtime.

Why customers choose DLX

Our customers value the stability and precision that DLX heating tapes bring to their processes. The combination of our alloy expertise and custom manufacturing capabilities enables us to offer heating solutions that perform under the most demanding laboratory and industrial conditions.

With years of experience in the resistance heating industry, DLX continues to innovate through material upgrades, improved temperature uniformity, and enhanced safety designs. We are committed to delivering products that not only meet today’s industrial requirements but also anticipate tomorrow’s challenges.

As industries move toward more energy-efficient, precise, and digitally controlled heating systems, DLX remains at the forefront by integrating smart heating technologies and advanced materials. Our R&D team is continually exploring new alloys and insulation systems to enhance performance while reducing energy waste.

DLX’s mission is simple — to provide reliable, durable, and efficient heating tapes that empower laboratories and chemical industries worldwide. Through high-quality materials, innovative engineering, and exceptional customer support, we help our partners achieve temperature control excellence with confidence.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is a glass fiber braided heating tape used for?

It’s used for heating laboratory glassware, chemical reactors, and process pipes that require stable, localized heating.

2. How high can it heat?

Most glass fiber braided heating tapes can continuously operate up to 450°C, depending on the alloy and configuration.

3. Can it be used in corrosive chemical environments?

Yes. The glass fiber braid and NiCr wire provide excellent resistance to chemical corrosion and oxidation.

4. Is it flexible enough for curved surfaces?

It’s moderately flexible, allowing easy wrapping around small-diameter pipes or lab glass equipment.

5. What voltages are available?

Standard options include 110V, 220V, and customizable voltages for different industrial systems.

6. Can it be used in outdoor conditions?

While it can resist heat and chemical exposure, it’s best suited for indoor or protected environments due to limited water resistance.

7. How long does it last?

With proper handling, the service life can exceed 5 years, especially when used below maximum rated temperatures.

8. Why choose DLX’s glass fiber braided heating tapes?

DLX offers heating tapes made from in-house alloy wires, ensuring stable heating, consistent quality, and full customization for temperature, length, and voltage.