From our DLX melt masters, GH3030 is an 80% nickel-20% chromium solid-solution alloy, with titanium 0.15-0.35% adding that extra oxide stability and minor hardening. Iron, manganese, and silicon are kept under 1% each to maintain purity, carbon maxes at 0.10% to avoid carbide woes, and phosphorus/sulfur are ultra-low (≤0.020%) to dodge brittleness. No heavy molybdenum or niobium here – keeps it straightforward and cost-effective while hitting UNS or GB/T specs. Density clocks in at 8.40 g/cm³, light enough for easy handling but tough for high-heat duties.

Mechanically, it's built for balance. Annealed, room-temp yield around 240-310 MPa, tensile 600-750 MPa, elongation 35-45% for smooth coiling or stamping into complex shapes. Crank to 700°C, and it retains 150-200 MPa tensile with creep under 1% in 1000 hours at 80 MPa stress – oxidation shrugs off 800°C continuous, forming stable chromia layers that resist spalling in air or mildly corrosive gases. Thermal conductivity ~15 W/m·K at RT, expansion 14.0 x 10^-6 /°C – tuned to minimize warping in cycles. Corrosion? Solid against aqueous acids, alkalies, and dry gases; resists stress cracking in chlorides better than many. Welds like a dream with GTAW/SMAW (no preheat, low hot-cracking), machines at 25-35 m/min with HSS tools. We draw it into 0.1-5mm diameters at DLX, arc-melting in vacuum for <10 ppm impurities – recyclable to 95%, aligning with our scrap-based runs that slash environmental impact.

For more details, pls directly contact us.

GH3030 wire excels where corrosion and heat collide. Chemical processing? Our fave – drawn for reactor linings or valve stems in nitric or sulfuric plants, enduring mixed acids at 500°C without pitting. We've supplied coils for heat exchanger tubes in petrochemical crackers, where oxidation resistance cuts leaks 35% and boosts run times. Heat processing? Furnace muffles and retorts handle 800°C annealing without scaling, perfect for metalworking kilns or glass melting.

Aero sneaks it for non-critical exhaust parts resisting fuel gases, while power gen uses it for boiler supports in steam at 600°C. At DLX, we tailor: fine wires for thermocouples in corrosive monitors, heavy for baskets in heat-treat ovens – annealed for formability. It slashes replacements 25% over irons while handling thermal shocks, amping efficiency in desal to pharma. When atmospheres turn nasty, GH3030 wire from DLX holds the line.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Peering ahead to 2025, superalloys are exploding – market kicking off at $7.82 billion, barreling to $17.75 billion by 2032 with a 12.4% CAGR. Aerospace and energy snag big shares, but chemical/heat processing rises with bio-refineries needing corrosion-proof alloys like GH3030 for sustainable fuels. Green shifts: H2 production and CCS demand oxidation-resistant wires for 700°C+ ops, aligning with net-zero pushes.

Eco mandates lead – recycled Ni at 50%, our DLX melts hit 60%, trimming footprints 30%. Additive booms: 3D-wire for custom reactors, wasting less 40%. Challenges? Ni prices up 10%, but DLX stabilizes. China's 9.8% fuels our exports; global invests $20B in greens. R&D? Nano-coatings for 20% res boosts, hybrids for EV thermal. For chem/heat pros, 2025's opportunity – sustainable alloys like GH3030 retooling.

DLX's Edge: Why We're the Smart Pick

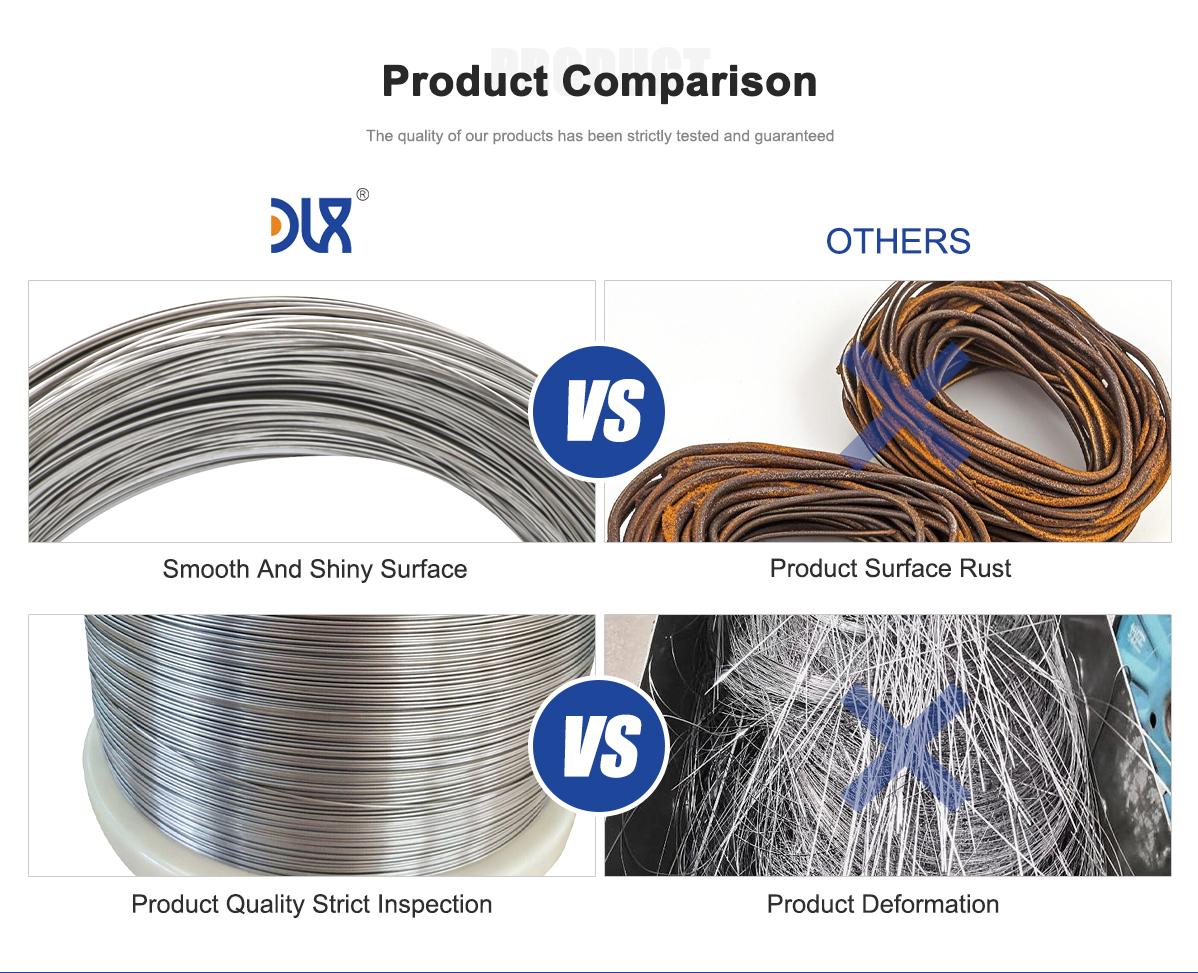

Facing alloy suppliers, DLX dominates with GH3030 wire cleaner, swifter, superior. Some churn spotty batches – impurities scaling early or diameters wobbling, failing your quals. Us? Vacuum-arc and probes nail ±0.005mm – zero defects. Leads? They drag 10-14 weeks; we stock 3-5, customs 7.

Custom? Wizards – tweak Ti for oxides or add finishes for corrosives, GB certed. Costs? 15-25% leaner sans dips, ops efficient – budgets breathe. Wins: 40% longer oxidation in tests vs. averages, pure chem paying off. Green? 65% recycled, aiming 80% '27, outpacing 30% norms. Support? Teams sim designs – not ship-bye. In harsh markets, DLX turns excellence to your advantage.

Specs at a Glance: GH3030 Table

Numbers show it – DLX GH3030 vs. standard Ni-Cr (basic) and precipitation-hardened super (extreme). GH3030 wins balanced res.

| Parameter | DLX GH3030 Wire | Standard Ni-Cr | Precip-Hardened Super |

|---|---|---|---|

| Composition (Key %) | Ni 80, Cr 20, Ti 0.15-0.35 | Ni 80, Cr 20 | Ni 50-55, Cr 17-21, Nb 5 |

| Yield Strength (MPa, Annealed) | 240-310 | 200-300 | 1035 |

| Tensile Strength (MPa) | 600-750 | 600-800 | 1275 |

| Max Service Temp (°C) | 800 (continuous) | 1150 (short) | 700 |

| Oxidation Resistance | Excellent to 900°C | Good to 1100°C | Excellent to 980°C |

| Creep Rupture (1000h @ 700°C, MPa) | 80-120 | 50-100 | 300-400 (at 650°C) |

| Weldability | Excellent | Excellent | Good (PWHT) |

| Density (g/cm³) | 8.40 | 8.30 | 8.19 |

| Cost Relative | Baseline | 85-95% | 200-250% |

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We field these daily – here's the no-BS.

GH3030's oxidation edge? Cr-Ti layers shield to 900°C; stable in chem gases without flake.

Creep handling? Solid at 700°C moderate loads; holds in heat-treat without sag.

Weld tips? GTAW no preheat – low cracks, clean for full res.

Fatigue in cycles? 10^7 at 150 MPa, good for vibrating fixtures.

Low-temp? Ductile -100°C, mixed apps fine.

Machining? Low hardening; HSS 30 m/min, coolant – easy.

Green factor? 95% recyclable, low-energy fits audits.

DLX sizes/times? 0.1-5mm annealed; 3-5 weeks stock, 7 customs – speedy.

Wrapping: Shield with DLX GH3030

That's GH3030 wire unpacked – from chem to surges. At DLX, we're crafting alloys that defy corrosives, fueling chem and heat ahead. Our purity, hustle, savvy give the win – gear up, stay resistant.