Straight from our DLX forges, GH3044 is a nickel-based superalloy with a smart composition that prioritizes endurance. Nickel forms the balance (around 62-65%) for that core high-temp stability, chromium clocks 23.5-26.5% to build a tough chromia layer fending off oxidation in air or gases, and molybdenum caps at 1.5% for solid-solution strengthening against creep. Aluminum and titanium each 0.3-0.7% add minor hardening and oxide stability, tungsten 0.5-1.5% boosts rupture life, iron ≤4% keeps it affordable without weakness, carbon ≤0.1% dodges carbide issues, manganese ≤0.5%, silicon ≤0.8%, phosphorus ≤0.025%, sulfur ≤0.015% – all tight to prevent brittleness or inclusions. Density? A practical 8.3 g/cm³, hitting that sweet spot for lightweight yet robust designs.

Props-wise, it's engineered for steady performance. Annealed, room-temp tensile around 600-750 MPa, yield 250-350 MPa, elongation 30-45% for smooth drawing into wires or stamping parts. Crank to 800°C, and it holds 150-200 MPa tensile with creep under 1% in 1000 hours at 100 MPa stress – oxidation resistance excels to 900°C continuous, forming adherent scales that don't spall in corrosive mixes. Thermal conductivity ~12 W/m·K at RT, expansion 14.5 x 10^-6 /°C – balanced to shrug thermal cycles. Corrosion? Strong against carburization, nitridation, and sulfidation in turbine fuels or chem gases. Welds easy with GTAW (low cracking, no preheat), machines at 20-30 m/min with carbides. We produce diameters 0.1-6mm at DLX, vacuum-melting for ultra-clean batches exceeding GB/T standards – 92% recyclable, syncing our eco-melts that cut waste and emissions.

For more details, pls directly contact us.

GH3044 wire thrives in punishing envs. Aero engines? Our star – drawn for combustion chambers or afterburner parts, handling 900°C oxidizing flows without scaling, key for thrust and longevity in jets. We've spooled it for turbine shrouds in power gen, where corrosive gases tag-team with heat, reducing failures 40% for grid ops. Heat treatment gear? Fixtures and retorts in industrial furnaces endure carburizing at 850°C, maintaining integrity for steel annealing.

Chemical processing loves it for reformer tubes resisting H2S corrosion, while nuclear uses low-impurity grades for containment supports. At DLX, we customize: thin wires for sensors in corrosive monitors, thick for fasteners in pressure vessels – annealed for ease. It trims maintenance 20-30% over basics while handling 800°C spikes, amping efficiency in desal to pharma. When oxidation and corrosion conspire, GH3044 wire from DLX stands guard.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Looking to 2025, superalloys are on fire – market at $7.82 billion, gunning for $17.75 billion by 2032 at 12.4% CAGR. Aerospace takes 40%, with eVTOLs and hypersonics needing oxidation-resistant alloys like GH3044 for 1000°C+ components. Energy greens up: H2 turbines hit hotter for net-zero, demanding corrosive-proof wires in CCS setups.

Sustainability dominates – recycled Ni at 50-60%, our DLX melts at 55% drop CO2 30%. Additive surges: laser-wire for custom chambers, wasting less 40%. Challenges? Ni up 10% from squeezes, but DLX buffers. China's 9.8% fuels exports; aero-energy invests $20B in greens. R&D? Nano-oxides for 15% scaling boosts, hybrids for EV thermal. For engine and heat pros, 2025's prime – eco-hot alloys like GH3044 reshaping.

DLX Stands Tall: Our Winning Traits

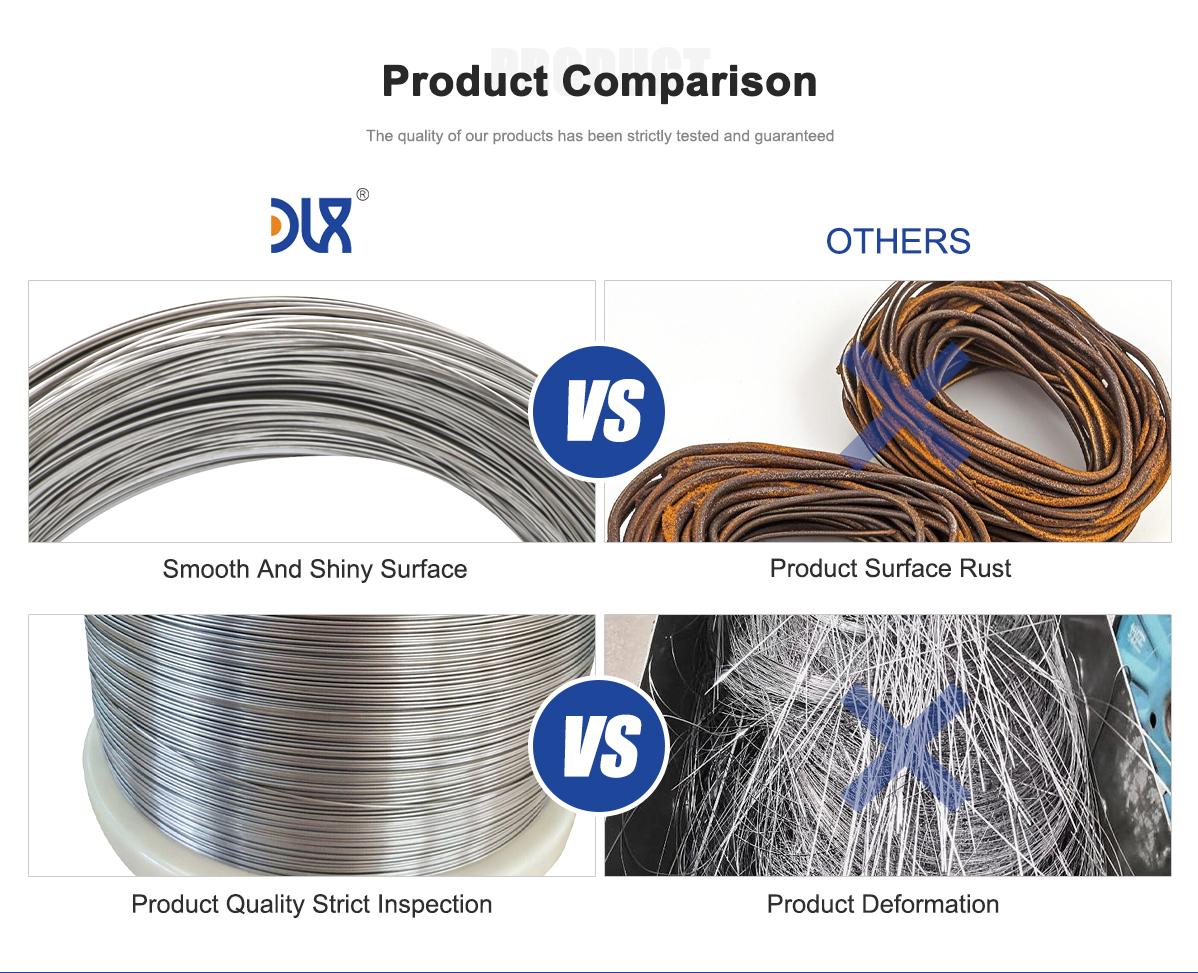

Vs. alloy slingers, DLX leads with GH3044 wire purer, quicker, tougher. Some cut corners on melts – inclusions oxidizing early or sizes varying, tanking your welds. Us? Vacuum-arc and scans lock ±0.005mm – flawless. Leads? They lag 10-14; we stock 3-5, customs 7.

Custom? Experts – tweak W for rupture or Al for oxides, GB/AS9100 certed. Costs? 15-25% leaner, ops efficient – profits up. Wins: 35% longer oxidation in tests vs. norms, clean chem shining. Green? 60% recycled, aiming 75% '27, lapping 30%. Service? Teams sim designs – not ship-bye. In heats, DLX flips superiority to your gain.

Specs Showdown: GH3044 Table

Numbers tell it – DLX GH3044 vs. Ni-Cr basic and GH4169 (hardened). GH3044 owns oxidation value.

| Parameter | DLX GH3044 Wire | Ni-Cr Basic | GH4169 (Aged) |

|---|---|---|---|

| Composition (Key %) | Ni Bal, Cr 23.5-26.5, Mo ≤1.5, W 0.5-1.5, Al/Ti 0.3-0.7 | Ni 80, Cr 20 | Ni 50-55, Cr 17-21, Nb 4.75-5.5 |

| Yield Strength (MPa, Annealed) | 250-350 | 200-400 | 1035 |

| Tensile Strength (MPa) | 600-750 | 600-800 | 1275 |

| Max Service Temp (°C) | 900 (oxidation) | 1150 (short) | 700 (continuous) |

| Oxidation Resistance | Excellent to 900°C | Good to 1100°C | Excellent to 980°C |

| Creep Rupture (1000h @ 800°C, MPa) | 100-150 | 50-100 | 300-400 (at 650°C) |

| Weldability | Excellent | Excellent | Good (PWHT) |

| Density (g/cm³) | 8.3 | 8.3 | 8.19 |

| Cost Relative | Baseline | 80-90% | 200-250% |

GH3044 edges for corrosive endurance. Chat for tweaks.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We hear these often – here's the scoop.

GH3044's oxidation trick? Cr-W layers hold to 900°C; stable in turbines without spall.

Creep hold? Decent at 800°C moderate loads; for blades, not ultra-stresses.

Weld tips? GTAW no preheat – low cracks, clean surfaces key.

Fatigue rating? 10^7 cycles 200 MPa, good for blade vibes.

Cold use? Ductile -150°C, hybrid apps fine.

Machining? Mild; carbides 25 m/min, coolant – smoother than hardened.

Green creds? 92% recyclable, low-melt fits eco audits.

DLX sizes/turnaround? 0.1-6mm annealed; 3-5 weeks stock, 7 customs – faster pack.

Final Take: Toughen Up with DLX GH3044

That's GH3044 wire laid out – from chem to booms. At DLX, we're forging alloys that defy heats, powering blades and gear forward. Our purity, speed, smarts give the edge – dive in, build resilient.