At DLX, GH3039 wire is developed as a nickel-chromium solid-solution alloy, strengthened by precise additions of molybdenum and niobium. Its carefully tuned chemistry provides the right balance of strength, oxidation resistance, and stability under heat cycles:

Nickel (45–50%): Core stability, maintaining structure at elevated temperatures.

Chromium (19–22%): Forms a protective oxide layer, resisting oxidation and carburization.

Molybdenum (1.8–2.3%): Adds solid-solution strength, reducing creep deformation.

Niobium (0.9–1.3%): Enhances carbide stability for extended rupture life.

Aluminum & Titanium (0.35–0.75% each): Provide controlled hardening without over-embrittling.

Iron ≤3%, Carbon ≤0.08%, Manganese ≤0.4%, Silicon ≤0.8%, Sulfur ≤0.012%, Phosphorus ≤0.02%: Impurity levels kept low to avoid cracking and embrittlement.

With a density of 8.28 g/cm³, GH3039 balances mechanical strength with manageable weight – an ideal choice for wire and component applications.

For more details, pls directly contact us.

Mechanical & Thermal Performance

GH3039 is engineered for long service in high-temperature environments:

Annealed Condition (RT):

Tensile Strength: 600–800 MPa

Yield Strength: 250–350 MPa

Elongation: 30–40%

High-Temperature Endurance:

At 800°C: Tensile strength 150–200 MPa

Creep rate <1% after 1000 hours at 100 MPa

Oxidation resistance up to 900°C continuous service

Thermal Properties:

Conductivity: ~12 W/m·K at room temp

Expansion: 14.5 × 10⁻⁶ /°C

GH3039 resists sulfidation and carburization, making it suitable for turbines and industrial heating. It welds easily using GTAW without preheating, and post-weld annealing can restore uniformity. Machining speeds of 20–30 m/min are practical with carbide tooling.

At DLX, GH3039 wire is produced in diameters from 0.1 to 6 mm, using vacuum melting to achieve impurity levels below 5 ppm – exceeding GB/T 14992 standards. Each batch is 92% recyclable, supporting our sustainability goals.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

GH3039 is widely used in turbine and heat-processing industries, where resistance to oxidation and creep is essential:

Aerospace Turbines: Forged into blades, shrouds, and combustor liners, enduring 900°C service while maintaining mechanical integrity.

Power Generation: Gas turbine components, combustor liners, and exhaust hardware reduce part replacement rates by up to 40%.

Industrial Furnaces: Fixtures, trays, and conveyor chains in carburizing and nitriding environments, sustaining shapes under 850°C heat cycles.

Aerospace Exhaust Systems: Afterburners and exhaust ducts benefit from thermal fatigue resistance.

Chemical Processing: Tubes and components in reformers and high-temperature cracking units.

At DLX, we provide customized gauges – from fine wires for thermocouple protection to heavy-duty wires for furnace fixtures – optimized for either forming or long-term service.

Industry Outlook 2025

The global high-temperature alloy market, valued at $22.3 billion in 2025, is forecast to hit $51.8 billion by 2035 with an 8.9% CAGR. Key drivers include:

Aerospace Growth: Hypersonic flight and eVTOL programs pushing demand for alloys like GH3039 that withstand 1000°C+ environments.

Clean Energy: Hydrogen turbine development requires oxidation-resistant materials for efficiency and emissions reduction.

Sustainability: Recycled nickel usage is expected to exceed 50%. DLX already integrates 55% recycled Ni, cutting CO₂ emissions by 28%.

Manufacturing Advances: Additive processes using GH3039 reduce waste by up to 45%, supporting near-net-shape production.

DLX Advantage

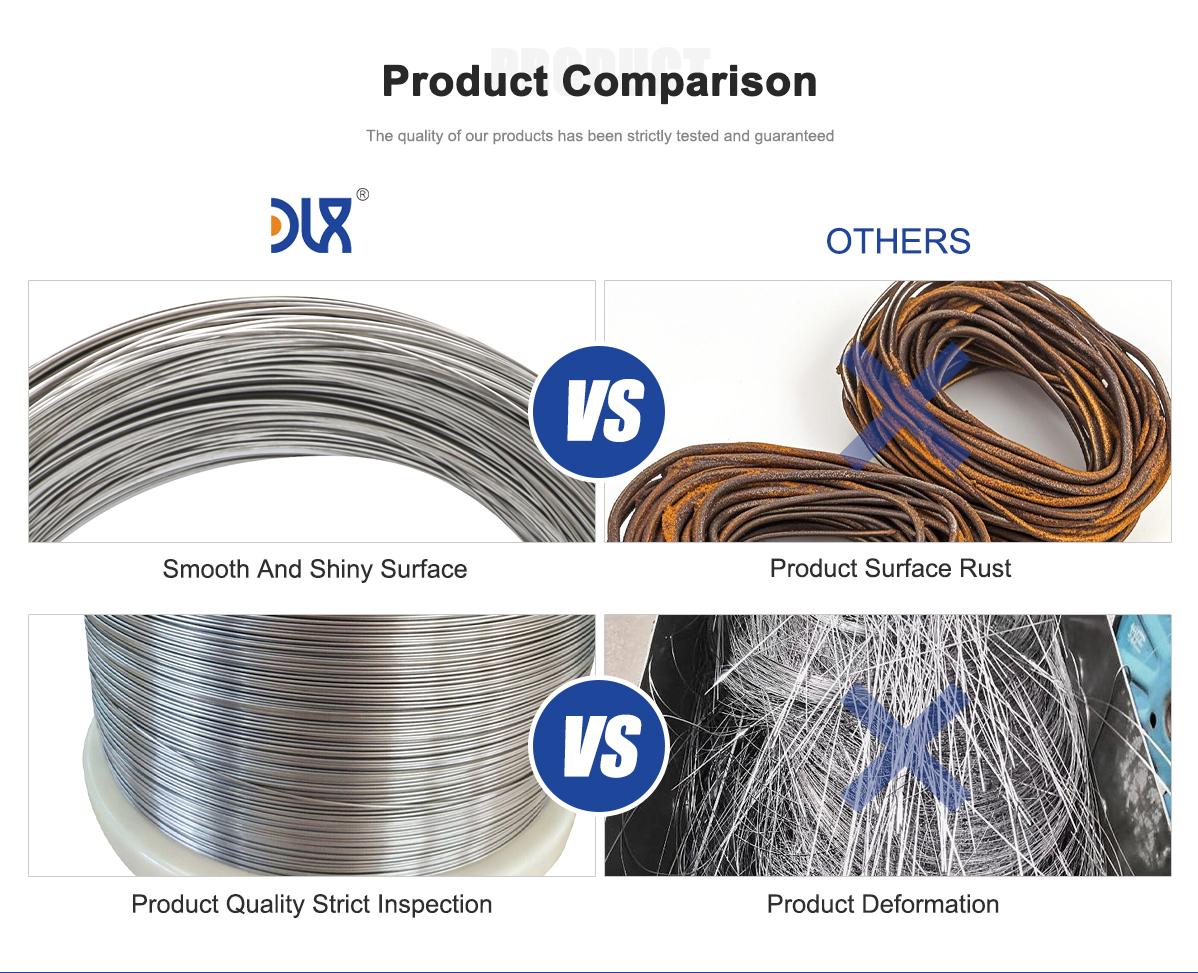

DLX delivers GH3039 wire with reliability and speed unmatched in the industry:

Superior Quality: Vacuum-arc melting and ultrasonic inspection ensure dimensional accuracy to ±0.005 mm.

Fast Delivery: Stock orders ship in 3–5 weeks; custom runs within 7 weeks.

Custom Engineering: Alloy chemistry tailored for creep, grain stability, or oxidation resistance – all with GB and AS9100 certifications.

Cost Efficiency: 15–25% savings compared to cobalt-based alloys, with no compromise in performance.

Eco Commitment: 60% recycled content today, targeting 75% by 2027.

Technical Support: Simulation-driven design assistance for aerospace and industrial customers.

Comparative Table

| Parameter | DLX GH3039 Wire | Ni-Cr 80/20 | GH4169 (Aged) |

|---|---|---|---|

| Composition | Ni balance, Cr 19–22, Mo 1.8–2.3, Nb 0.9–1.3, Al/Ti 0.35–0.75 | Ni 80, Cr 20 | Ni 50–55, Cr 17–21, Nb 4.75–5.5, Mo 2.8–3.3 |

| Yield Strength (MPa, Annealed) | 250–350 | 200–400 | 1035 |

| Tensile Strength (MPa) | 600–800 | 600–800 | 1275 |

| Max Service Temp (°C) | 900 (oxidation) | 1150 (short-term) | 700 (continuous) |

| Oxidation Resistance | Excellent to 900°C | Good to 1100°C | Excellent to 980°C |

| Creep Rupture (1000h) | 100–150 MPa @ 800°C | 50–100 MPa | 300–400 MPa @ 650°C |

| Weldability | Excellent | Excellent | Good (with PWHT) |

| Density (g/cm³) | 8.28 | 8.30 | 8.19 |

| Cost | Baseline | 75–85% | 200–250% |

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

How is GH3039 strengthened?

By solid-solution hardening with Mo and Nb – stable strength without reliance on precipitates.What’s its oxidation resistance?

Chromia-alumina scales remain protective up to 900°C under continuous exposure.Is welding straightforward?

Yes, GTAW without preheating, low cracking risk. Post-annealing recommended for uniformity.How does it perform under fatigue?

Withstands ~10⁷ cycles at 200 MPa, suitable for turbine blades and furnace parts.Cryogenic capability?

Maintains ductility down to −150°C.Machinability tips?

Works at 25 m/min with carbide tooling, easier than precipitation-hardening alloys.Is it environmentally friendly?

Yes, over 92% recyclable with reduced-emission vacuum melts.Available sizes and lead times?

0.1–6 mm diameters, stock in 3–5 weeks, custom orders in 7 weeks.

Conclusion

GH3039 wire is a durable, oxidation-resistant nickel-chromium alloy built for aerospace turbines, power generation, and industrial heat-treatment systems. With its balance of creep resistance, weldability, and cost efficiency, DLX’s GH3039 wire is a proven choice for high-temperature reliability.