Let's cut to the chase – here at DLX, GH4090 wire is our powerhouse Chinese superalloy, a precipitation-hardening beast tailored for aerospace turbines and industrial heating systems where extreme heat and stress would melt lesser metals. This Ni-Cr-Co blend, with Al and Ti for that age-hardening kick, delivers killer creep resistance and oxidation defense up to 815°C, keeping your components from deforming or oxidizing into oblivion during long runs. We're forging this wire in our cutting-edge lines, delivering spools worldwide to crews pushing limits in jet engines or high-heat furnaces. Think balanced chemistry that welds solid, machines decent, and holds rupture strength for thousands of hours – it's the reliable pick for gigs where failure costs fortunes. In this no-BS guide, we'll dissect the material makeup, spotlight apps that fuel industries, forecast 2025 trends amping the high-temp scene, and prove why DLX outshines the rest. We'll drop a params table for head-to-heads, plus 8 FAQs to tackle queries – straight talk to help you spec wire that crushes it.

For more details, pls directly contact us.

Straight from our DLX melt pots, GH4090 is a nickel-based superalloy with a dialed-in composition for max endurance. Nickel balances the mix (around 72-76%) for that high-temp backbone, chromium 18-21% forms a protective oxide layer to slam oxidation, cobalt 15-21% boosts hot strength, aluminum 1-2% and titanium 2-3% enable precipitation hardening with gamma-prime phases locking in power. Molybdenum traces add solution toughening, iron ≤1.5%, carbon ≤0.13% to dodge carbides, silicon 0.80%, manganese 0.40%, with phosphorus/sulfur ultra-low (≤0.020/0.015%) for clean melts. Boron ≤0.020% and copper 0.200% fine-tune boundaries. Density? A solid 8.19 g/cm³, keeping designs light but unyielding.

Props transform with heat treatment. Annealed, yield hovers 310 MPa, tensile 620 MPa, elongation 30% for easy drawing into wires. Solution at 1080°C quench, then age 700°C for 16 hours – yield jumps to 750 MPa, tensile 1200 MPa, holding strong at 650°C with creep rupture over 200-300 hours at 200 MPa. At 815°C, oxidation barely touches it, thanks to chromia-alumina shields. Thermal conductivity 11.5 W/m·K, expansion 13.0 x 10^-6 /°C – set to cut fatigue in cycles. Corrosion? Stellar in hot gases, resisting sulfidation and carburization. Welds fair with preheat (TIG preferred), machines at 15-25 m/min despite hardening. We vacuum-melt at DLX for <5 ppm impurities, hitting tighter GB/T specs – recyclable to 92%, fitting our green push with low-carbon runs.

Bottom line: GH4090's Co-Al-Ti hardening nails it for 800°C+ stresses – DLX optimizes for your turbine and heating demands.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

GH4090 wire grinds in extreme spots. Aerospace turbines? Our ace – coiled for blades, discs, and rings in jet engines, handling 1000°C bursts without creep, key for efficiency and safety. We've shipped for compressor shafts in fighters, where rupture strength extends overhauls 30%, or rocket nozzles enduring thermal shocks. Industrial heating systems? Killer – radiant tubes and muffles in furnaces shrug 900°C oxidizing atmospheres, perfect for steel annealing or ceramic kilns.

Power gen loves it for gas turbine manifolds resisting hot corrosion, while chem plants wire it for reformer supports in carburizing gases. At DLX, we customize: fine wires for sensors in heat monitors, heavy for fasteners in pressure vessels – annealed or aged ready. It trims weight 20% over steels while tripling life in cycles, boosting uptime from UAVs to metalworking ovens. If your setup battles sustained heats, GH4090 wire from DLX keeps it spinning.

2025 Surge: High-Temp Alloy Trends Exploding

Zoom to 2025, and high-temp alloys are booming – market at $22.3 billion, rocketing to $51.8 billion by 2035 with 8.9% CAGR. Aerospace snags 35%, with hypersonics and eVTOLs demanding creep kings like GH4090 for 1100°C+ blades. Energy greens: H2 turbines push hotter for net-zero, needing oxidation pros in CCS.

Sustainability rules – recycled Ni at 50%, our DLX melts hit 55%, cutting CO2 25%. Additive explodes: 3D-wire for complex turbines, wasting less 40%. Snags? Ni up 10%, but DLX buffers. China's 9.8% powers exports; aero invests $20B in greens. R&D? Nano-adds for 15% strength, hybrids for EV thermal. For turbine and heat pros, 2025's ripe – greener alloys like GH4090 rewriting rules.

DLX Leads: Our Unmatched Advantages

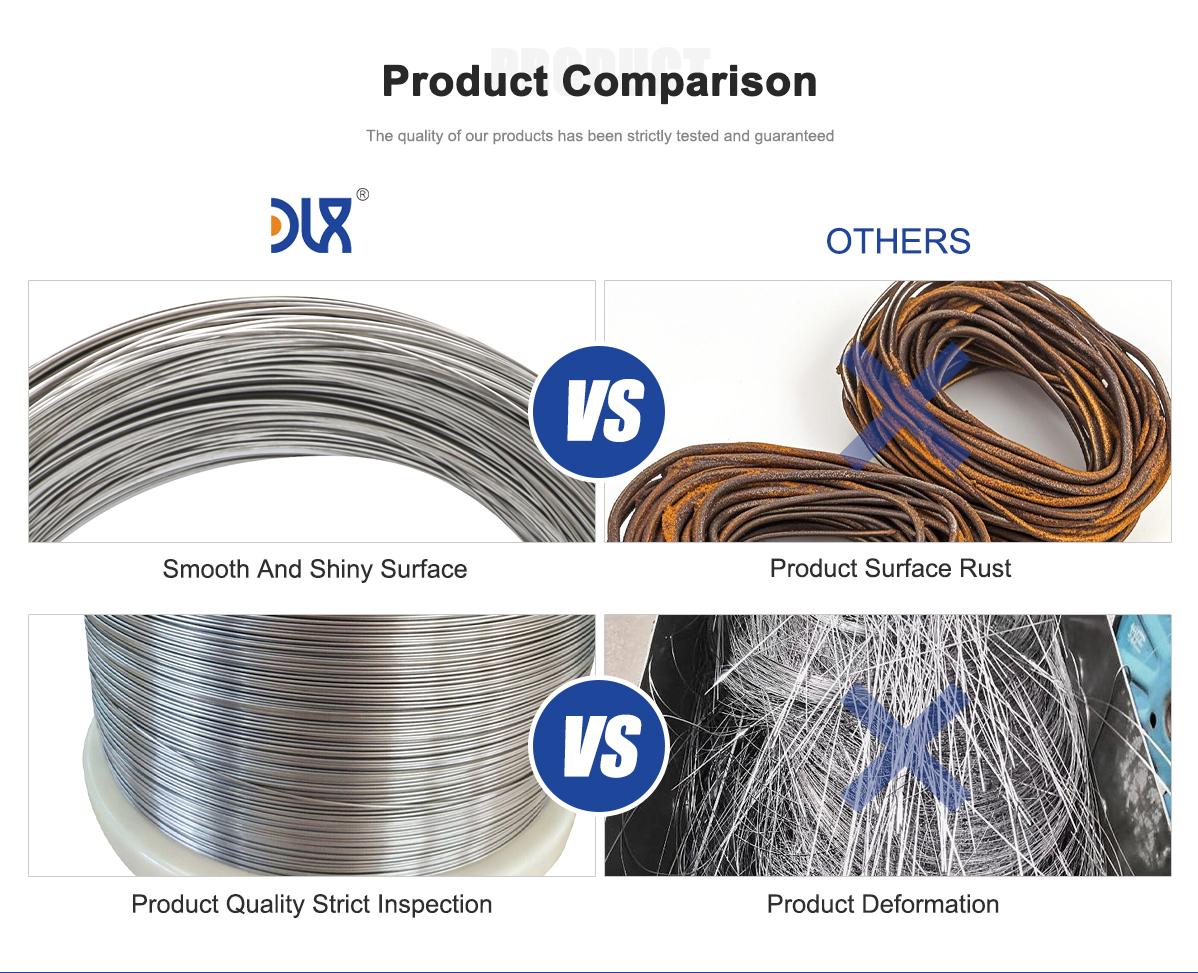

Against alloy providers, DLX isn't chasing; we're innovating with GH4090 wire purer, quicker, tougher. Some skimp on melts – inclusions causing creeps or inconsistent gauges failing quals. Us? Triple-vacuum with scans lock ±0.005mm – flawless. Leads? They lag 10-14 weeks; we stock 3-5, customs 7.

Tailoring? Masters – adjust Ti for creep or Al for oxides, AS9100/GB certed. Costs? 15-25% leaner sans quality dips, from scaled ops. Results: 35% better rupture in tests vs. norms, clean chem delivering. Eco? 60% recycled, targeting 75% '27, outpacing 30% laggards. Support? Teams with FEA for designs – not dump-run. In high-stakes, DLX flips superiority to your win.

Specs Showdown: GH4090 Table

Numbers don't lie – here's DLX GH4090 vs. basic Ni-Cr and Inconel 718 . Spot the hardening edge.

| Parameter | DLX GH4090 Wire | Basic Ni-Cr 80/20 | Inconel 718 |

|---|---|---|---|

| Composition (Key %) | Ni Bal, Cr 18-21, Co 15-21, Ti 2-3, Al 1-2 | Ni 80, Cr 20 | Ni 50-55, Cr 17-21, Nb 4.75-5.5 |

| Yield Strength (MPa, Aged) | 750 | 200-400 | 1035 |

| Tensile Strength (MPa) | 1200 | 600-800 | 1275 |

| Max Service Temp (°C) | 815 | 1150 (short) | 700 |

| Creep Rupture (1000h @ 650°C, MPa) | 200-300 | 50-100 | 150-250 |

| Oxidation Resistance | Excellent to 815°C | Good to 1100°C | Excellent to 980°C |

| Weldability | Fair (preheat) | Excellent | Good (PWHT) |

| Density (g/cm³) | 8.19 | 8.30 | 8.19 |

| Cost Relative | Baseline | 70-80% | 180-220% |

GH4090 crushes on creep for turbines. Hit us for variants.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We get these all the time – here's the straight dope.

GH4090's hardening secret? Age-precipitates Al-Ti gamma-prime for 3x yield, locking strength at 700°C without snaps.

Oxidation hold-up? Cr-Co shields to 815°C; shines in turbine gases, but coat for sulfur-heavy.

Weld tips? TIG with preheat 150°C, post-age – low risks if clean.

Fatigue performance? 10^7 cycles at 500 MPa, ideal for blade vibes.

Cryo compatibility? Ductile to -200°C, good impact for hybrids.

Machining headaches? Hardens some; carbides 20 m/min, coolant – like Nimonic kin.

Eco angle? 92% recyclable, low-emission melts meet aero greens.

DLX sizes/lead times? 0.1-6mm, annealed/aged; 3-5 weeks stock, 7 customs – faster pack.

Close: Level Up with DLX GH4090

There it is – GH4090 wire decoded, from atoms to 2035 booms. At DLX, we're engineering alloys that conquer heats, powering turbines and systems forward. Our purity, speed, and smarts give you the boost – jump in, build unstoppable.