At DLX, our GH4169 wire is a precision-engineered nickel-iron-chromium superalloy. Its composition is designed for high-temperature strength, oxidation resistance, and structural stability:

Nickel (50–55%): Core element ensuring excellent performance under thermal stress.

Chromium (17–21%): Forms a protective oxide layer for oxidation and sulfidation resistance.

Iron (balance): Provides toughness while keeping costs efficient.

Niobium (4.75–5.5%) with tantalum: Stabilizes carbides and forms delta phase to control creep.

Molybdenum (2.8–3.3%): Enhances solid-solution strengthening.

Titanium (0.65–1.15%) & Aluminum (0.2–0.8%): Enable gamma-prime and gamma-double-prime precipitates during aging for superior hardening.

Carbon (0.02–0.08%), Manganese/Silicon (≤0.35%), Phosphorus/Sulfur (≤0.015%): Minimize brittleness.

Boron (0.002–0.006%): Improves grain boundary toughness.

With a density of 8.19 g/cm³, GH4169 delivers lightweight performance suitable for aerospace without compromising strength.

For more details, pls directly contact us.

Mechanical Properties

GH4169 is a versatile performer. When solution-annealed at 980–1040°C and rapidly cooled:

Yield Strength: 550–650 MPa

Tensile Strength: 900–1100 MPa

Elongation: 25–35%

After double-aging (720°C for 8 hours, furnace cooled to 620°C for 8 hours):

Yield Strength: ≥1035 MPa

Tensile Strength: 1275 MPa

High-Temperature Hold: 550 MPa at 650°C, creep life >200 hours at 345 MPa

Other key mechanical features:

Fatigue resistance: Up to 10⁷ cycles at 500 MPa

Creep: <1% deformation over 1000 hours at 650°C/300 MPa

Thermal conductivity: 11.4 W/m·K at room temperature

Thermal expansion: 13.0 ×10⁻⁶ /°C

The alloy resists oxidation and sulfidation up to 980°C, with optional aluminizing for extreme hotspots. It is weldable using matching filler, preheated to 150°C, with post-weld heat treatment restoring mechanical properties. Machining is feasible at 20–30 m/min despite rapid hardening.

DLX produces GH4169 using vacuum-melting to keep impurities below 10 ppm, exceeding GB/T 14992 standards. The wire is 90% recyclable, supporting sustainability initiatives.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Applications in Aerospace and Power

GH4169 wire excels where reliability under extreme conditions is critical:

Aerospace: Springs for landing gear, turbine discs, compressor blades, and rocket casings endure 700°C spins and extreme vibrations. Fatigue-resistant properties extend maintenance cycles by 30%.

Power Generation: Gas turbine shafts, rotors, and high-temperature fasteners handle continuous stress while boosting efficiency in combined-cycle plants.

Nuclear: Control rods and structural components resist radiation and corrosion.

Oil & Gas: Downhole tools tolerate sour well H₂S environments.

Customized Solutions: DLX provides fine wires for sensors, heavier gauges for pressure vessels, in either solution-annealed or aged conditions.

GH4169 wires reduce weight by ~20% versus steel, quadruple service life in >600°C cycles, and improve fuel efficiency across aerospace and power applications.

Industry Trends 2025 and Beyond

Nickel-based superalloys are booming. The market projected at $13.23B in 2025, reaching $20.44B by 2031 at 5.59% CAGR. Key drivers:

Aerospace: eVTOLs, hypersonic vehicles, and 800°C+ propulsors demand creep-resistant wires.

Power Generation: Hydrogen and combined-cycle turbines require oxidation-resistant alloys for net-zero goals.

Sustainability: DLX uses 55% recycled nickel, cutting CO₂ emissions by 25%.

Additive Manufacturing: Powder-bed methods with GH4169 reduce waste by ~35%.

Challenges include nickel price volatility, but DLX’s vertical integration mitigates supply risks. Ongoing R&D explores nano-precipitates for 15% strength gains and hybrid applications for EV thermal management.

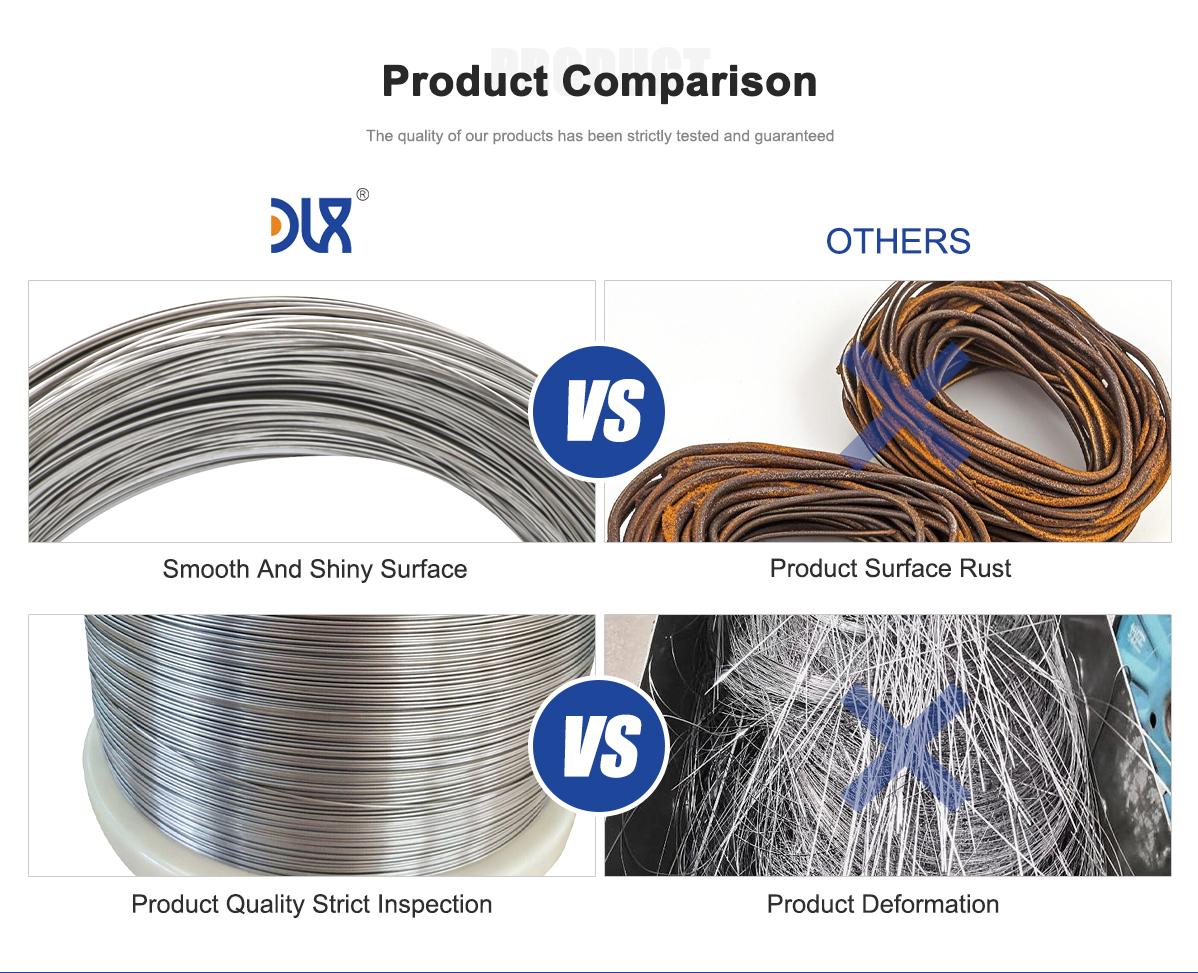

DLX Advantage

DLX is not just a supplier; we optimize GH4169 for consistency, performance, and sustainability:

Precision Production: Triple-vacuum melts, laser-monitored diameters ±0.002 mm.

Speed: Stock wires 4–6 weeks, customs 8 weeks.

Customization: Adjust Nb for creep, boron for grain boundary toughness; AS9100/GB certified.

Cost Efficiency: 15–25% savings versus competitors.

Sustainability: 60% recycled content now, 75% by 2027.

Technical Support: FEA-based design assistance for aerospace and power teams.

Comparative Specs Table

| Parameter | DLX GH4169 Wire | Inconel 718 | Inconel 625 |

|---|---|---|---|

| Ni (%) | 50–55 | 50–55 | 58+ |

| Cr (%) | 17–21 | 17–21 | 20–23 |

| Nb (%) | 4.75–5.5 | 4.75–5.5 | 3.15–4.15 |

| Mo (%) | 2.8–3.3 | 2.8–3.3 | 8–10 |

| Ti (%) | 0.65–1.15 | 0.65–1.15 | — |

| Al (%) | 0.2–0.8 | 0.2–0.8 | — |

| Yield Strength MPa | ≥1035 | ≥1035 | 275–350 |

| Tensile Strength MPa | 1275 | 1275 | 600–800 |

| Max Service Temp °C | 700 | 700 | 650 |

| Creep Rupture (1000h @650°C MPa) | 345+ | 345+ | 100–150 |

| Oxidation Resistance | Excellent to 980°C | Excellent to 980°C | Superior to 1100°C |

| Weldability | Good (PWHT) | Good (PWHT) | Excellent |

| Density g/cm³ | 8.19 | 8.19 | 8.44 |

| Relative Cost | Baseline | 100–110% | 150–200% |

GH4169 matches Inconel 718 in high-temperature hardening while offering superior fatigue performance for aero and power applications.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

How does GH4169 harden? Double-aging produces gamma-prime and gamma-double-prime precipitates, doubling yield strength while maintaining ductility at 650°C.

Oxidation/corrosion resistance? Cr-Nb protective layers resist air, fuels, and sulfidation to 980°C; coating recommended for acids.

Welding advice? GTAW with matching filler, preheat 150°C, age post-weld.

Fatigue performance? 10⁸ cycles at 500 MPa for turbine applications.

Cryogenic compatibility? Maintains toughness down to −253°C.

Machining tips? Use 20 m/min with flood coolant; watch carbide hardening.

Environmental benefits? 90% recyclable; low CO₂ emissions in production.

Available sizes? 0.1–10 mm, solution-annealed or aged; stock 4–6 weeks, custom 8 weeks.

Conclusion

GH4169 wire from DLX is engineered for extreme conditions, delivering Inconel 718-level performance with enhanced fatigue, creep, and corrosion resistance. Optimized for aerospace, power generation, nuclear, and oil/gas applications, DLX ensures reliable, sustainable, and high-performance superalloys for your most demanding projects.