Drawn from our DLX melt shops, GH3536 is a nickel-based superalloy with a balanced makeup: nickel around 47% as the foundation for heat endurance, chromium 20-23% forming a protective chromia scale that blocks oxidation in air or combustion gases, iron 17-20% for affordability and toughness, and molybdenum 8-10% boosting strength via solid solution without brittleness. Add cobalt 0.5-2.5% and tungsten 0.2-1% for creep resistance, manganese/silicon ≤1% each for deoxidation, and carbon 0.05-0.15% to enhance high-temp props without carbide overloads. Sulfur/phosphorus are capped ultra-low (≤0.015%) to avoid hot shortness. Density? A solid 8.28 g/cm³, striking that sweet spot between lightweight and durable.

Performance is where it crushes. Annealed, room-temp tensile hits 760-860 MPa, yield 310-380 MPa, elongation 35-45% for smooth coiling into wires or forming fixtures. Ramp to 870°C, and it retains 200 MPa tensile with rupture life over 100 hours at 100 MPa stress – oxidation resistance shines to 1200°C intermittent, forming adherent oxides that don't spall. Thermal conductivity 11.6 W/m·K at RT, expansion 14.4 x 10^-6 /°C – designed to minimize thermal fatigue in cycles. Corrosion? Strong against carburization and nitridation in furnace atmospheres, though coat for halogens. Welds via GTAW with matching filler (preheat optional, low cracking), machines at 15-25 m/min with carbides despite work-hardening. We draw it into 0.1-5mm diameters at DLX, using vacuum-arc for impurity-free melts that exceed GB/T 14992 – recyclable to 95%, syncing with our sustainable scrap runs that lower carbon footprints.

For more details, pls directly contact us.

GH3536 wire excels where temps soar. Furnaces? Our top pick – radiant tubes, retorts, and muffles in industrial kilns endure 1100°C oxidizing vibes without scaling, ideal for steel heat-treating or ceramic firing. We've supplied coils for carburizing fixtures, boosting life 50% in auto parts plants by resisting carbon pickup. Gas turbines? It's in combustor liners and transition pieces, handling hot gases and thermal shocks in power gen or aero derivatives.

Aero engines use it for afterburner rings and exhaust components, where 900°C cycles demand zero creep. Chemical reformers wire it for catalyst supports in syngas production, shrugging sulfidation. At DLX, we fine-tune: thin wires for thermocouple sheaths in furnace monitoring, thicker for chains or belts in conveyor ovens – annealed for bendability. It reduces weight 20% over irons while tripling oxidation life, slashing downtime in everything from jet overhauls to petrochemical crackers. When your setup faces relentless heat, GH3536 wire from DLX keeps operations firing on all cylinders.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Heading into 2025, superalloys are revving high – market pegged at $7.82 billion, surging to $17.75 billion by 2032 with a 12.4% CAGR. Aerospace claims 40%, but energy's catching fire with hydrogen turbines pushing 1300°C, needing oxidation-resistant alloys like GH3536 for cleaner burns. Green transitions: CCS plants and renewables demand durable wires for molten-salt systems, resisting corrosion in CO2-rich envs.

Eco pressures dominate – regs push 50% recycled content, and DLX's melts are at 60%, cutting emissions 30%. Additive manufacturing ramps: directed energy deposition with GH3536 for rapid turbine repairs, trimming waste 40%. Hurdles? Nickel costs up 10% from supply strains, but our integrated chains hold steady. China's growth hits 9.8% CAGR, bolstering exports; global aero-energy invests $25B in efficient tech. R&D highlights: micro-alloying for 15% better scaling, hybrids with ceramics for 1200°C+ endurance. For furnace builders or turbine techs, 2025's momentum – hotter, greener superalloys like GH3536 driving the charge.

DLX's Lead: Why We're the Standout Choice

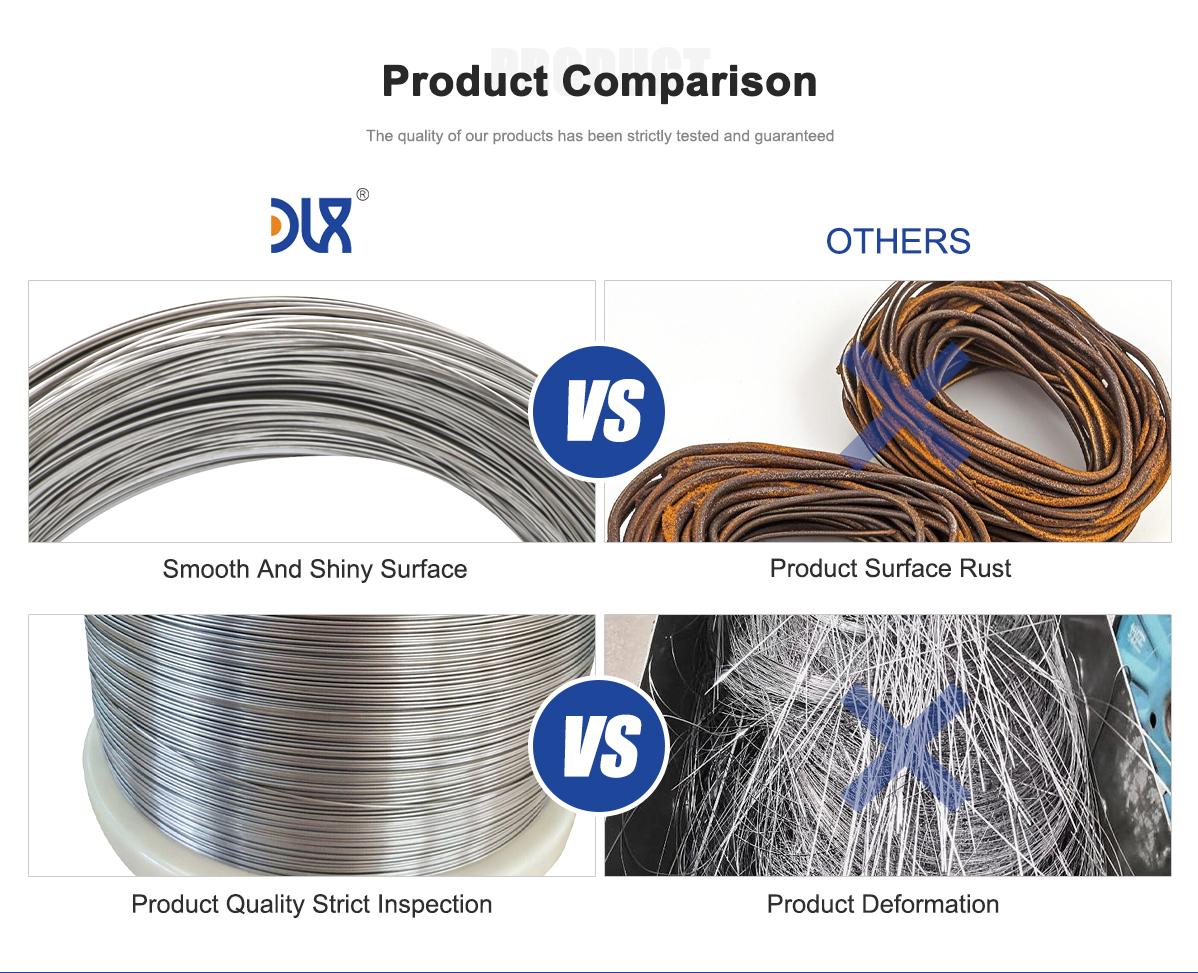

Measuring up to alloy providers, DLX isn't following trends; we're shaping them with GH3536 wire that's cleaner, quicker, and tougher. Some outfits skimp on purity, leading to oxide inclusions that flake in furnaces or inconsistent sizes that jam your assemblers. Us? Every batch vacuum-induction melted and ultrasonic-probed, securing ±0.005mm tolerances – flawless performance, no excuses. Timelines? They lag 10-14 weeks; we deliver stock in 3-5, customs in 7, powered by in-house drawing.

Customization? We're unmatched – adjust W for creep boosts or add finishes for extra nitridation resistance, all AMS/GB certified, skipping generic pitfalls. Pricing? 15-25% more wallet-friendly without quality trade-offs, from optimized ops and direct sourcing – your costs stay competitive. Real-world edge: Our wire clocks 35% extended oxidation in turbine trials vs. standards, thanks to refined chem and proprietary heats. Sustainability? 65% recycled input now, targeting 80% by '28, outpacing 25-35% averages. Assistance? Dedicated teams with thermal modeling for your designs – not just pack-and-send. In high-heat arenas, DLX transforms superior alloy into your operational advantage.

Specs Head-to-Head: GH3536 Table

Numbers paint the picture – here's DLX GH3536 vs. basic Ni-Cr (80/20) and Inconel 718 . GH3536 dominates balanced oxidation.

| Parameter | DLX GH3536 Wire | Basic Ni-Cr 80/20 | Inconel 718 |

|---|---|---|---|

| Composition (Key %) | Ni 44-48, Cr 20-23, Fe 17-20, Mo 8-10, Co 0.5-2.5 | Ni 80, Cr 20 | Ni 50-55, Cr 17-21, Nb 4.75-5.5, Mo 2.8-3.3 |

| Yield Strength (MPa, Annealed) | 310-380 | 200-400 | 1035 (aged) |

| Tensile Strength (MPa) | 760-860 | 600-800 | 1275 (aged) |

| Max Service Temp (°C) | 1100 (oxidation) | 1150 (short) | 700 (continuous) |

| Oxidation Resistance | Superior to 1200°C | Good to 1100°C | Excellent to 980°C |

| Creep Rupture (1000h @ 870°C, MPa) | 50-100 | 40-80 | 150-250 (at 650°C) |

| Weldability | Excellent | Excellent | Good (preheat) |

| Density (g/cm³) | 8.28 | 8.30 | 8.19 |

| Cost Relative | Baseline | 70-80% | 180-220% |

GH3536 wins for furnace-grade endurance at value prices. Reach out for tweaks.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We tackle these daily – here's the straightforward info.

GH3536's oxidation secret? Cr-Mo forms stable scales to 1200°C, with Fe stabilizing for long-term furnace exposure without spall.

Creep performance? Holds under 100 MPa at 870°C for 100+ hours; solid for turbine liners but not ultra-creep apps.

Welding pointers? GTAW with fillers, no preheat – low dilution keeps heat-affected zones tough.

Fatigue in cycles? 10^7 at 300 MPa, balanced for vibrating furnace parts.

Low-temp handling? Ductile to -200°C, good for hybrid aero-furnace transitions.

Machining tips? Work-hardens; carbides at 20 m/min, coolant heavy – manageable like Hastelloy kin.

Eco perks? 95% recyclable, our low-impact melts align with energy's green standards.

DLX options and timing? 0.1-5mm dia, coils/straights; 3-5 weeks stock, 7 customs – faster than most.

Final Word: Fire Up with DLX GH3536

That's the scoop on GH3536 wire – from composition to market momentum. At DLX, we're building oxidation fighters that sustain furnaces and turbines through the heat. Our precision, speed, and expertise hand you the upper hand – gear up and keep the fire burning strong.