Straight from our DLX forges, GH3625 packs a nickel base (58% min) for killer stability in extremes, chromium 20-23% crafting a passive oxide film that slams the door on corrosion, and molybdenum 8-10% ramping resistance to reducing acids like HCl or H2SO4. Niobium (3.15-4.15%) teams with tantalum traces for carbide stabilization, preventing sensitization during welds, while iron ≤5%, manganese ≤0.5%, and silicon ≤0.5% keep it clean and ductile. Carbon's tight at ≤0.10%, phosphorus/sulfur ≤0.015% to dodge embrittlement, and no heavy cobalt for cost smarts. Density clocks 8.44 g/cm³ – hefty but ideal for structural integrity without bulk.

For more details, pls directly contact us.

Props-wise, it's a survivor. Annealed, tensile strength 600-800 MPa, yield 275-350 MPa, elongation 40-50% for easy drawing into 0.2-8mm wires. At 650°C, it holds 400 MPa tensile with <1% creep over 1000 hours under 100 MPa stress. Fatigue? Over 10^7 cycles at 300 MPa, pitting potential >1V in seawater – no cracks in chloride stress. Thermal conductivity 9.9 W/m·K at RT, expansion 13.3 x 10^-6 /°C – balanced for minimal distortion in cycles. Corrosion game? Elite in phosphoric, nitric, and mixed acids; resists intergranular attacks post-weld. Welds via GTAW/SMAW with matching filler (no preheat needed, low hot-cracking risk), machines at 15-25 m/min with carbides. We vacuum-melt at DLX for ultra-low inclusions, hitting GB/T 14992 specs – recyclable to 90%, aligning with our eco-melts that cut waste.

Simply put, GH3625 is your corrosion shield with high-temp staying power – DLX refines it for chem-proof reliability.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

GH3625 wire isn't for show; it's grinding in corrosive fronts. Chemical processing? Our breadwinner – woven into screens for acid reactors or drawn for valve stems in phosphoric plants, enduring H3PO4 at 200°C without pitting. We've spooled it for heat exchanger tubes in sulfuric setups, slashing leaks 45% for processors. Offshore oil? Wire ropes and springs shrug H2S and brine in sour wells, extending subsea life.

Pulp/paper mills love it for digester linings against bleaches, while pollution control scrubs SO2 in flue gas ducts without sulfidation fails. Aerospace sneaks it for fuel lines resisting jet fuels, and marine apps coil it for propeller shafts in saltwater. At DLX, we adapt: fine wires for sensors in chem monitors, thick for fasteners in pressure vessels – annealed for fab, aged for strength. It trims maintenance 20-30% over SS while handling 500°C spikes, fueling efficiency in desal plants to pharma reactors. When corrosion's the enemy, GH3625 wire from DLX is your frontline defense.

2025 Surge: Superalloy Trends Heating Up

Eyeing 2025, superalloys are on a rocket – market at $7.82 billion, blasting to $17.75 billion by 2032 with 12.4% CAGR. Chem processing snags 25%, driven by green chem shifts like bio-refineries needing acid-resistant wires for ethanol or biodiesel. Sustainability's boss: recycled Ni mandates reach 60%, and our DLX melts hit 65%, dropping emissions 35%.

Additive tech booms – laser-wire deposition with GH3625 for custom reactor parts, cutting prototypes 50%. Energy transitions: LNG and H2 plants demand crevice-proof alloys for cryogenic-corrosive mixes. Snags? Mo prices up 10% from supply pinches, but DLX's chains keep steady. China's slice grows 9.5% CAGR, powering exports; global chem invests $18B in corrosion upgrades. R&D? Nano-Nb for 20% better pitting, hybrids with ceramics for 800°C pushes. For chem engineers, 2025's ripe – durable, green superalloys like GH3625 reshaping resilient ops.

DLX's Dominance: Why We Lead the Pack

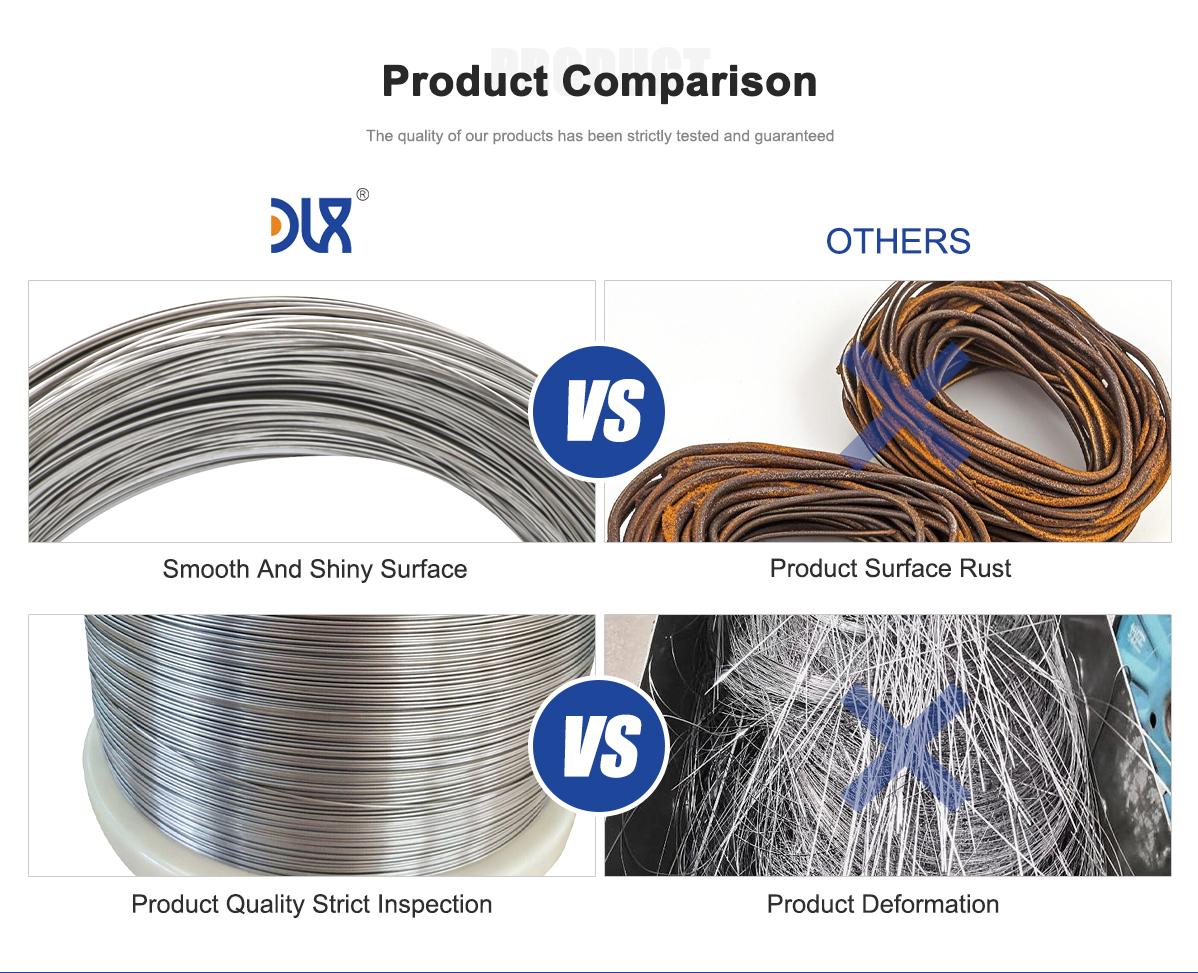

Against alloy suppliers, DLX isn't trailing; we're innovating ahead with GH3625 wire that's purer, faster, unbeatable. Some crank inconsistent batches – oxides sparking pits or diameters wobbling, tanking your welds. Us? Quad-vacuum refined with eddy scans, nailing ±0.003mm – zero flaws. Leads? They drag 9-15 weeks; we ship stock 3-5, customs 7, from automated mills.

Tailoring? Experts – boost Nb for acid tweaks or add coatings for crevice shields, all GB/ASME certed, not vanilla stock. Costs? 12-22% leaner without dips, via efficient runs and sourcing – profits pop. Field wins: Our wire logs 40% longer in acid tests vs. averages, cleaner chem and proprietary draws delivering. Eco edge: 70% recycled now, aiming 85% by '28, surpassing 30% laggards. Service? Chem pros with corrosion sims for your rigs – not ship-and-dip. In corrosive markets, DLX flips superior wire to your bottom-line boost.

Param Clash: GH3625 Table

Check the matchups – DLX GH3625 vs. austenitic SS (basic 316) and Hastelloy C-276 (Mo-heavy cousin). GH3625 rules balanced corrosion.

| Parameter | DLX GH3625 Wire | Austenitic SS 316 | Hastelloy C-276 |

|---|---|---|---|

| Composition (Key %) | Ni 58+, Cr 20-23, Mo 8-10, Nb 3.15-4.15 | Ni 10-14, Cr 16-18, Mo 2-3 | Ni 57, Cr 16, Mo 16, W 4 |

| Yield Strength (MPa, Annealed) | 275-350 | 205-290 | 355 |

| Tensile Strength (MPa) | 600-800 | 515-690 | 790 |

| Max Service Temp (°C) | 650 (continuous) | 925 (intermittent) | 1093 |

| Pitting Resistance (PREN) | 40-45 | 25-30 | 45-50 |

| Creep Rupture (1000h @ 650°C, MPa) | 100-150 | 20-50 | 200-300 |

| Corrosion in H2SO4 | Excellent | Good | Superior |

| Density (g/cm³) | 8.44 | 8.00 | 8.89 |

| Cost Relative | Baseline | 40-50% | 250-300% |

GH3625 edges value for chem corrosion. Hit us for customs.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We get these nonstop – here's the scoop.

GH3625's corrosion edge? Mo-Nb combo boosts pitting res in chlorides; PREN 45 means no crevice fails in seawater or acids.

High-temp hold? Solid to 650°C with creep <1%; not for 1000°C but aces chem heats without softening.

Weld tips? GTAW filler matches, no preheat – low dilution keeps corrosion props intact.

Fatigue in vibes? 10^8 cycles at 400 MPa, Nb stabilizing for pump or agitator wires.

Cryo use? Ductile to -196°C, good for LNG chem lines without brittle snaps.

Machining gotchas? Gums mildly; carbide at 20 m/min, oil lube – smoother than high-Mo.

Green factor? 90% recyclable, our low-energy melts meet chem's eco regs.

DLX sizes/deliveries? 0.2-8mm, annealed; 3-5 weeks stock, 7 customs – quicker than norms.

Wrap: Armor Up with DLX GH3625

That's GH3625 wire broken down – from elements to market blasts. At DLX, we're forging corrosion conquerors that safeguard chem futures. Our purity, speed, and savvy give you the win – lock in and shield your ops.