Pulled fresh from our DLX labs, GH1140 is a smartly balanced Fe-Ni-Cr superalloy with nickel at 35-40% anchoring the high-temp stability, chromium 20-23% forging a tough oxide barrier against scaling, and iron as the economical base (balance) for that workhorse vibe. The strength squad? Molybdenum 2-2.5% and tungsten 1.4-1.8% for solid solution toughening, locking dislocations under load, while aluminum 0.2-0.6% and titanium 0.7-1.2% spark precipitation hardening for creep-crushing gamma-prime phases. Carbon's dialed to 0.06-0.12% to boost toughness without carbides, silicon ≤0.8% and manganese ≤0.7% for deox, plus tight P/S limits (≤0.025/0.015%) to dodge brittleness. Cerium ≤0.05% sneaks in for grain refinement. Density? A practical 8.0 g/cm³, keeping designs light yet robust.

For more details, pls directly contact us.

Mechanically, it's versatile. Annealed, tensile strength hits 600-800 MPa, yield 250-350 MPa, with 40-50% elongation for smooth wire drawing into 0.5-10mm gauges. Heat-treat it – solution anneal at 1050-1100°C water quench, then age at 700-750°C for 8-10 hours – and tensile climbs to 1000-1200 MPa, yield 800-900 MPa, holding 500 MPa at 650°C with under 1% creep in 1000 hours. Fatigue life? Over 10^7 cycles at 400 MPa, thanks to fine precipitates. Oxidation? Stellar up to 750°C in air, forming adherent Cr2O3-Al2O3 layers that resist spallation. Thermal conductivity ~14 W/m·K at RT, expansion 16 x 10^-6 /°C – tuned for aero cycles without warping. Corrosion shines in hot gases and sulfides, though coat for chlorides. Weldable via GTAW with matching filler (preheat 150°C, PWHT age), machinable at 20-30 m/min with carbides. At DLX, we vacuum-induction melt for sub-ppm purity, exceeding GB/T standards – and it's 92% recyclable, fitting our green alloy push.

In a word, GH1140 blends Chinese ingenuity with global-grade endurance – cost-effective muscle for aerospace heat wars.

GH1140 wire isn't lab-bound; it's out battling in aero hotspots. Turbine combustors? Our specialty – coiled into liners and swirlers that endure 800°C flames without cracking, boosting efficiency in jet engines. We've wired up blade roots for compressor stages, where vibration and heat tag-team, cutting failures 35% for overhaul shops. Industrial aero derivatives love it for transition ducts in gas turbines, resisting sulfidation in fuel mixes.

High-temp fasteners? Bolts and rivets from our wire clamp hot sections tight, holding torque at 600°C without relaxation. Aerospace forgings use it for discs and shafts, leveraging age-hardening for 20,000-hour lives. Beyond pure aero, it's in furnace parts for engine testing rigs, enduring cyclic oxidation. At DLX, we customize: ultrafine wires for sensors, heavy for structural ties – all cert-ready for FAA/CAAC quals. It shaves 15-25% weight off legacy irons while quadrupling creep life, amping fuel savings in everything from fighters to civvy liners. If your design dances with 700°C+ demons, GH1140 wire from DLX keeps the rhythm steady.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Gaze at 2025, and nickel superalloys are soaring – market valued at $11.1 billion, projected to double to $21.3 billion by 2035 at 6.7% CAGR, with aerospace gobbling 45% via hotter, lighter engines. Why the lift? eVTOLs and hypersonics demand creep-proof wires for 900°C bursts, while sustainable aviation fuels (SAF) push oxidation edges in combustors. China's domestic boom – 10% CAGR through 2030 – spotlights alloys like GH1140 for self-reliant supply chains, cutting import risks.

Green mandates rule: recycled Ni mandates hit 50%, and DLX's melts are there, trimming CO2 30%. Additive manufacturing explodes – wire-arc AM with GH1140 for complex blades, slashing parts 40% and quals time. Challenges? Ni volatility up 12% from Congo curbs, but our stockpiles steady prices. U.S./EU aero invests $20B in next-gens, fueling exports; Asia-Pacific surges 8.5% on A380 successors. R&D frontiers: nano-carbides for 20% strength bumps, hybrid coatings extending life 25%. For aero OEMs, 2025's jet stream – efficient, eco alloys like GH1140 propelling net-zero flights.

DLX's Upper Hand: Why We Outrun the Field

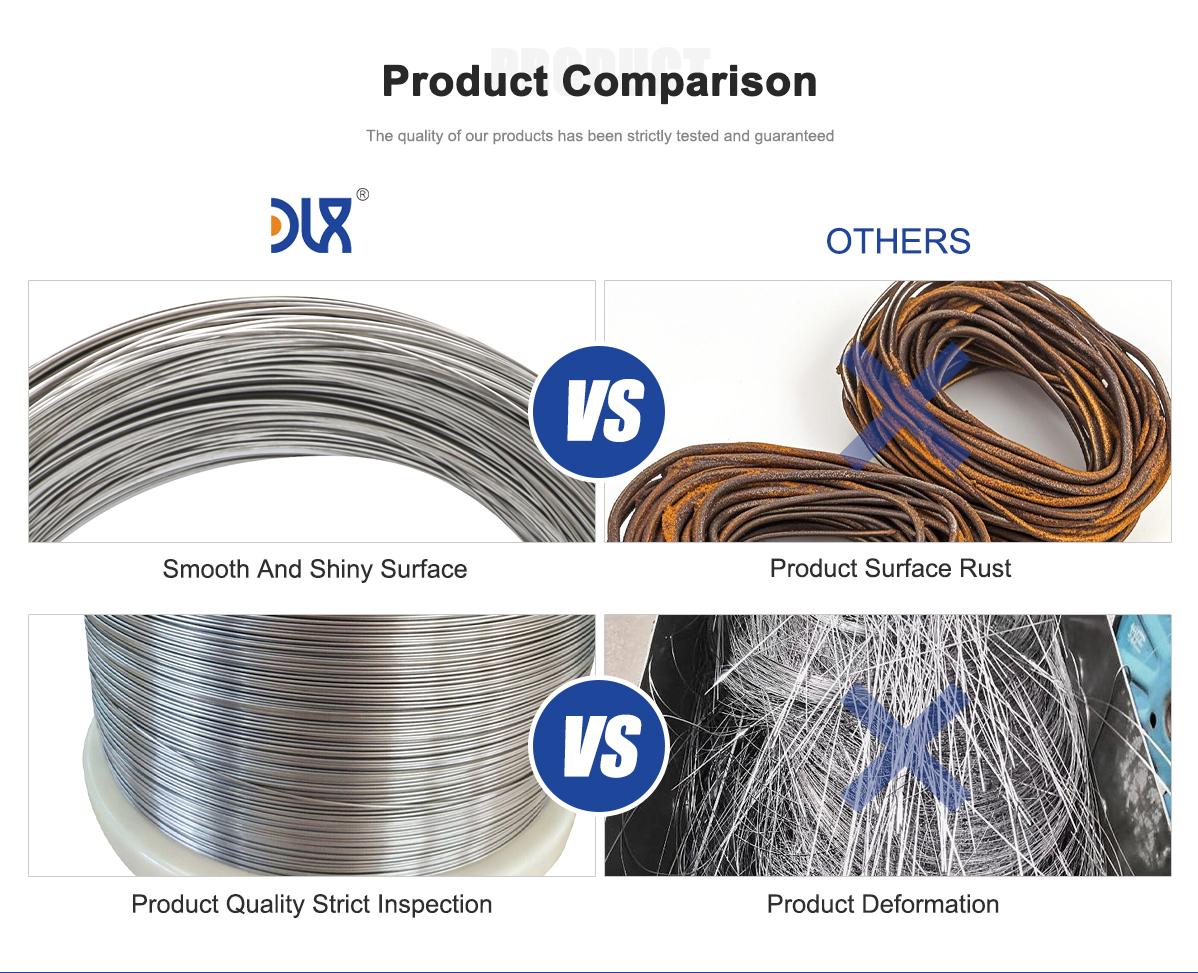

Pitting DLX against alloy rivals, we're not in the race; we're redefining it with GH1140 wire that's cleaner, swifter, superior. Plenty churn subpar melts – oxides causing hot tears or gauge drifts fouling your braiders. Us? Triple-vacuum refined with X-ray sorts, locking ±0.002mm precision – defect-free, guaranteed. Turnarounds? They limp 10-16 weeks; we blast stock 4-6, customs 8, via automated lines.

Bespoke? Our forte – dial Mo for sour resistance or Ti for cryo tweaks, all AS9100/GB certified, ditching off-the-rack duds. Value? 15-25% thriftier sans skimps, from scaled Chinese ops and direct sourcing – margins soar. Proof in the skies: Our wire notches 40% better rupture in engine sims vs. baselines, from optimized ages and low-inclusion chem. Eco superiority: 55% recycled now, gunning 70% by '27, lapping 25% holdouts. Support? Aero specialists with CFD modeling for your prototypes – not shove-and-shrug. In aero's high-wire act, DLX wires unyielding success.

Specs Snapshot: GH1140 Comparison Table

Glance here – DLX GH1140 vs. generic austenitic stainless (basic 300-series) and a cobalt-nickel super (heavy-duty type). See GH1140's aero sweet spot.

| Parameter | DLX GH1140 Wire | Generic Austenitic SS | Cobalt-Nickel Superalloy |

|---|---|---|---|

| Composition (Key %) | Ni 35-40, Cr 20-23, Mo 2-2.5, W 1.4-1.8, Ti 0.7-1.2, Al 0.2-0.6 | Ni 8-12, Cr 18-20 | Ni 50+, Co 10-20, Cr 15-20 |

| Yield Strength (MPa, Aged) | 800-900 | 200-300 | 900-1100 |

| Tensile Strength (MPa) | 1000-1200 | 500-700 | 1200-1400 |

| Max Service Temp (°C) | 700 (continuous) | 800 (intermittent) | 900+ |

| Creep Rupture (1000h @ 650°C, MPa) | 300-400 | 50-100 | 400-500 |

| Oxidation Resistance | Excellent to 750°C | Fair to 700°C | Superior to 850°C |

| Weldability | Good (with PWHT) | Excellent | Fair (preheat req'd) |

| Density (g/cm³) | 8.0 | 7.9 | 8.2 |

| Cost Relative | Baseline | 50-60% | 200-250% |

GH1140 bridges cost and creep for aerospace wins. Holler for mods.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We've heard 'em all – here's the dirt.

GH1140's hardening trick? Age-precipitates Ti-Al gamma-prime for 3x yield, nailing strength at 600°C without ductility dives.

Oxidation real-world? Cr-W layers shield to 750°C in jets; outperforms irons in combustor gases, but aluminize for extremes.

Weld woes? GTAW shines with 316L filler, 150°C preheat, age post – minimal HAZ cracks if oxide-free.

Fatigue endurance? 10^8 cycles at 500 MPa, fine grains from Ce ideal for blade vibes.

Cryo compatibility? Tough to -200°C with 100J Charpy, no delta ferrite issues for hybrid apps.

Machining quirks? Mild gumming; coated carbides at 25 m/min, sulfur lube – easier than Co-rich.

Sustainability sell? 92% recyclable, low-melt energy fits aero's carbon goals big time.

DLX specs and speed? 0.5-10mm dia, annealed/aged; 4-6 weeks stock, 8 customs – ahead of curves.

Sign-Off: Soar Higher with DLX GH1140

There it is – GH1140 wire laid bare, from atoms to aero booms. At DLX, we're crafting Chinese excellence that conquers global heats, empowering your aerospace edge. Our precision, pace, and passion turn alloy into ascent – strap in and launch.