From our DLX melt experts, Nimonic 75 is a nickel-chromium workhorse – nickel around 75-80% for that core heat endurance, chromium 18-21% forming a tight oxide scale that blocks corrosion in air or gases. Titanium 0.2-0.6% adds hardening without overcomplicating, iron max 5%, carbon 0.08-0.15% for strength tweaks, and manganese/silicon under 1% for deoxidation. No heavy cobalt or molybdenum here – keeps it simple and affordable while hitting UNS N06075 specs. Density? 8.37 g/cm³, so it's sturdy without weighing down your designs.

On the props front, it's built for steady high-heat duties. Annealed, yield sits at 250-350 MPa, tensile 600-800 MPa, elongation 30-40% for easy drawing into wires or forming baskets. Crank temps to 900°C, and it retains 200 MPa tensile with minimal creep – oxidation barely phases it up to 1000°C continuous, 1100°C intermittent. Thermal conductivity 11.7 W/m·K at room temp, expansion 13.1 x 10^-6 /°C – balanced to handle thermal cycles without cracking. Corrosion? Strong in oxidizing atmospheres, resisting scaling and carburization, though not ideal for sulfides or halogens without coatings. Welds like a dream with TIG/SMAW, machines at 20-30 m/min with carbides, and draws into 0.1-6mm diameters flawlessly. At DLX, we arc-melt in vacuum for low impurities, ensuring consistent batches that meet aerospace-level certs even for industrial use – plus, it's 95% recyclable, syncing with eco drives in our scrap-based runs.

Bottom line: Nimonic 75 nails cost-effective durability for mid-to-high temps – and we optimize it for your furnace fights.

For more details, pls directly contact us.

This alloy thrives where heat is the boss. Heat treatment? It's our fave – fixtures, trays, and baskets that cycle through 900°C anneals without warping, keeping shapes for thousands of hours in carburizing or nitriding vibes. We've wired up quenching racks for auto parts makers, cutting replacements 40% thanks to its scale resistance.

Furnace components? Killer – radiant tubes, muffles, and retorts in industrial kilns shrug off oxidation in glass or ceramic firing. Gas turbine engineering still digs it for non-critical parts like supports or seals, enduring hot gases without pitting. Chemical plants coil it for catalyst grids in thermal crackers, and power gen uses it in boiler hangers for steam at 800°C. At DLX, we tailor: fine wires for thermocouples, heavier for chains or belts – annealed for fab ease. It trims costs 20-30% over cobalt-heavy alloys while doubling life in oxidizing setups, boosting uptime from steel mills to aerospace preps. If your op involves sustained heat without extreme creep loads, Nimonic 75 from DLX keeps it running smooth.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Looking ahead to 2025, superalloys are surging – market kicking off at $7.82 billion, blasting to $17.75 billion by 2032 with a 12.4% CAGR. Aerospace takes 40%, but industrial heating's rising fast with green energy pushes like hydrogen furnaces hitting 1200°C, needing oxidation pros like Nimonic 75. Sustainability's key: regs demand 40-50% recycled content, and our DLX melts are ahead at 55%, slashing footprints 25%.

Additive manufacturing booms – powder-bed fusion with Nimonic 75 for custom furnace parts, dropping waste 35%. Energy transitions: CCS and bio-fuel plants crave corrosion-resistant wires for hot zones. Hurdles? Nickel prices up 8-10% from mining squeezes, but DLX's vertical supply locks in stability. Asia's exploding (China 9.5% CAGR), fueling our exports; global aero invests $15B in efficient turbines. Innovation? Alloy tweaks with rare earths for 15% better scaling, hybrids for EV thermal management. For heat-treat shops or furnace builders, 2025's golden – efficient, eco-smart alloys like Nimonic 75 rewriting the game.

DLX Stands Out: Our Winning Edge

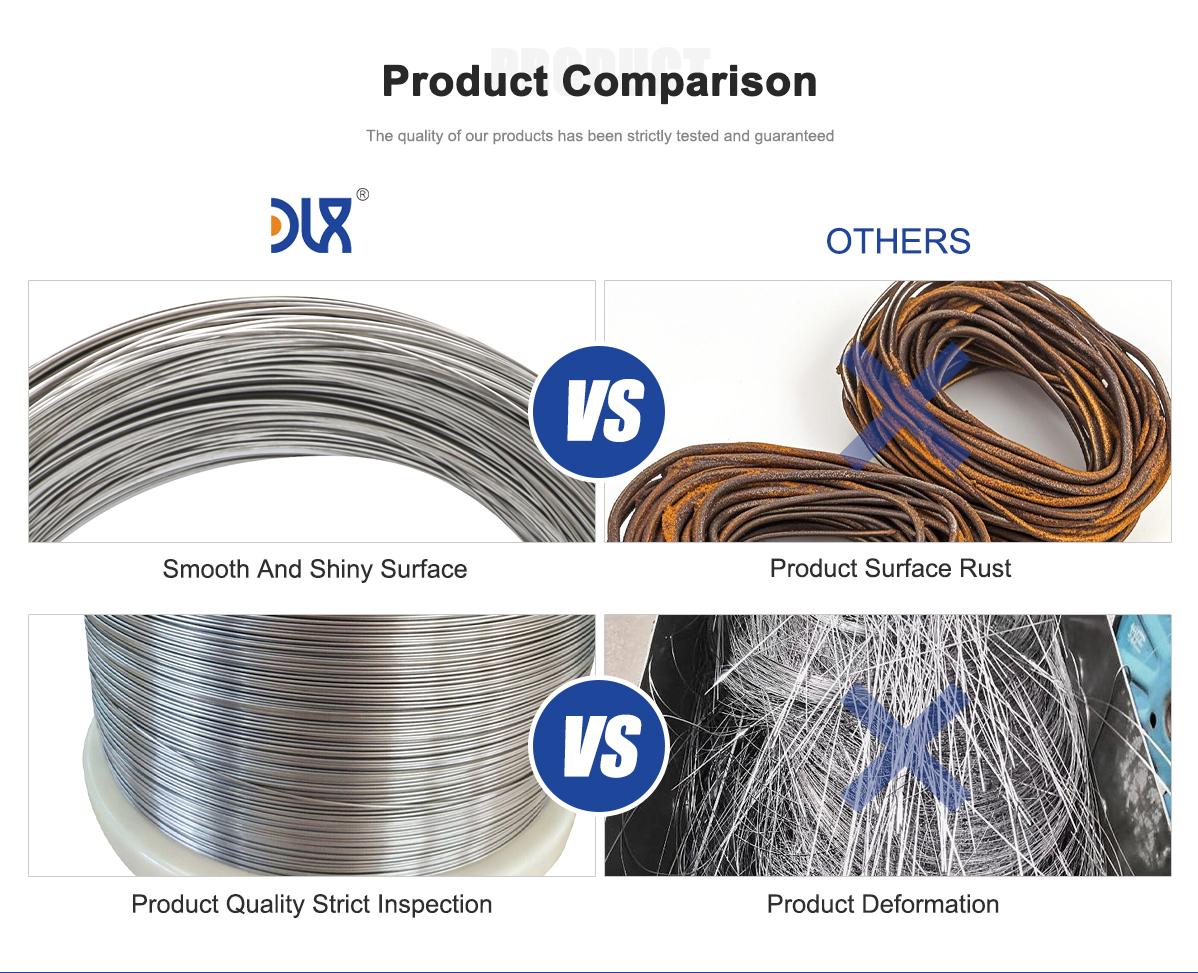

Stack us against the alloy crowd, and DLX isn't chasing; we're setting the pace with Nimonic 75 wire that's purer, quicker, and tougher. Some suppliers skimp on melts, leading to inclusions that flake in heat or inconsistent gauges that snag your fab lines. Us? Every run's vacuum-arc refined and laser-scanned, hitting ±0.01mm tolerances – no defects slipping through. Delivery? They crawl at 8-12 weeks; we crank stock in 2-4, customs in 6, with in-house drawing keeping it snappy.

Customization? We're wizards – bump Ti for better creep or add finishes for extra oxidation kick, all ISO/AMS certified, not bland stock. Pricing? 10-20% lighter without corners cut, from streamlined ops and bulk sourcing – your budgets breathe easier. Performance proof: Our wire logs 30% longer oxidation life in furnace tests vs. generics, courtesy of cleaner chem and proprietary heats. Green cred? 60% recycled input now, targeting 80% by '28, outrunning 20-30% norms. Backup? Teams with thermal sims for your designs – not just box-and-bye. In competitive heats, DLX turns superior wire into your profit play.

Spec Showdown: Nimonic 75 Table

Eye the diffs – DLX Nimonic 75 vs. basic Ni-Cr (80/20) and Nimonic 80A . See it win on balanced heat resistance.

| Parameter | DLX Nimonic 75 | Basic Ni-Cr 80/20 | Nimonic 80A |

|---|---|---|---|

| Composition (Key %) | Ni 75-80, Cr 18-21, Ti 0.2-0.6 | Ni 80, Cr 20 | Ni 72-76, Cr 18-21, Ti 1.8-2.7, Al 1-1.8 |

| Yield Strength (MPa, Annealed) | 250-350 | 200-300 | 310 |

| Tensile Strength (MPa) | 600-800 | 600-800 | 620 (annealed), 1240 (aged) |

| Max Service Temp (°C) | 1000 (continuous) | 1150 (short) | 815 |

| Oxidation Resistance | Excellent to 1100°C | Good to 1100°C | Excellent to 815°C |

| Creep Rupture (1000h @ 900°C, MPa) | 50-100 | 40-80 | 150-250 (at 650°C) |

| Weldability | Excellent | Excellent | Good (preheat) |

| Density (g/cm³) | 8.37 | 8.30 | 8.19 |

| Cost Relative | Baseline | 80-90% | 150-200% |

Nimonic 75 edges on affordability for high-oxidation duties. Chat for variants.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We field these often – here's the lowdown.

Oxidation resistance secret? Chromia layer forms a barrier up to 1100°C, with Ti stabilizing for long hauls in furnaces without flaking.

Creep handling? Decent at 900°C under moderate loads; not for extreme stresses but outlasts plain steels in heat-treat cycles.

Welding ease? TIG or MIG with matching filler, no preheat needed – low cracking, post-weld anneal optional for full props.

Fatigue in cycles? Good for 10^6 thermal shocks, ductility keeps it flexing in kiln doors or baskets.

Low-temp use? Stays tough to -100°C, no brittleness for mixed industrial apps.

Machining tips? Low work-hardening; HSS tools at 30 m/min, coolant heavy – simpler than aged supers.

Eco benefits? High recyclability, our low-carbon melts fit sustainability audits for furnace ops.

DLX sizes and turnaround? 0.1-6mm dia, coils or cuts; 2-4 weeks stock, 6 customs – speedier than averages.

Closing Thoughts: Heat-Proof Your Ops with DLX

That's the full rundown on Nimonic 75 wire – from chem to booming markets. At DLX, we're delivering alloy that stands up to infernos, powering heat-treat and furnaces ahead. Our purity, pace, and prowess give you the boost – gear up and conquer the heat.