Straight from our DLX forges, Nimonic 90 is a nickel-chromium-cobalt beast – nickel clocks in at 54% min for that high-temp backbone, chromium 18-21% building a rock-solid oxide layer to fend off corrosion, and cobalt 15-21% boosting hot strength without brittleness. The hardening heroes? Titanium 2-3% and aluminum 1-2%, forming tiny precipitates that lock in power during aging. Iron's capped at 1.5%, carbon 0.13% max to skip carbide issues, with manganese, silicon under 1%, and traces of boron, zirconium for grain control. Density? 8.18 g/cm³ – hefty but perfect for stability.

Props are where it shines. Annealed, yield's around 310 MPa, tensile 620 MPa, elongation 30% for coiling ease. Age it – solution at 1080°C quench, then 700°C for 16 hours – and yield hits 750 MPa, tensile 1200 MPa, with 20% stretch. At 815°C, creep rupture holds for thousands of hours under 200 MPa stress, oxidation barely touches it up to 920°C thanks to that chromia-alumina shield. Thermal conductivity 11.5 W/m·K, expansion 13.0 x 10^-6 /°C – tuned to cut thermal fatigue in cycles. Corrosion? Excels in hot gases, sulfidation, and carburizing vibes, though coat for wet halides. Welds decent with preheat (TIG preferred), machines at 15-25 m/min with carbides, and draws into wires 0.05-5mm without snaps. We at DLX vacuum-melt for impurity-free runs, hitting aero certs every time – eco-wise, 90% recyclable, fitting green pushes with our scrap-heavy melts.

In essence, Nimonic 90 bridges extreme heat endurance with fab-friendly traits – and DLX fine-tunes it for your hottest challenges.

For more details, pls directly contact us.

This wire thrives in hellish spots. Gas turbines? It's our star – blades, discs, and shafts spinning at 900°C, resisting creep so engines run longer, hotter. We've supplied coils for compressor rings that endure vibrations in power plants, slashing outages 30% for clients. Industrial heating? Furnace elements and radiant tubes glow red-hot without scaling, perfect for steel mills or glass kilns.

Aero loves it for exhaust valves and afterburner parts, handling thermal shocks in jets. Chemical plants wire it for catalyst supports in oxidizing reactors, while nuclear uses low-cobalt grades for tube hangers to cut activation. Auto? High-end racing bolts and springs that survive 800°C bursts. At DLX, we customize: fine gauges for sensors, thick for fasteners – annealed or aged ready. It drops weight 20% vs. steels, triples life in harsh cycles, amping efficiency from offshore platforms to space thrusters. If heat's your enemy, Nimonic 90 from DLX turns it into an ally.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Peering into 2025, superalloys are exploding – market at $7.82 billion, rocketing to $17.75 billion by 2032 with 12.4% CAGR. Aerospace grabs 40%, fueled by eVTOLs and hypersonics needing creep kings like Nimonic 90 for 1000°C+ props. Green energy booms: hydrogen turbines push 1400°C, demanding oxidation pros, while CCS rigs crave corrosion resistance in CO2 flows.

Sustainability rules – regs mandate 50% recycled nickel, and our DLX melts hit that, dropping emissions 28%. Additive tech surges: 3D-wire builds for turbine vanes, cutting waste 45%. Challenges? Nickel spikes 12% from shortages, but DLX's chains buffer it. Asia's hot (China 9.8% CAGR), boosting our exports; U.S. aero pours $12B into next-gens. R&D? Nano-boosts for 18% strength, hybrids with ceramics for 25% life. For OEMs in energy or aero, 2025's prime time – hotter, greener wins with Nimonic 90 leading.

DLX Edge: Why We're the Top Dog in Nimonic 90 Wire

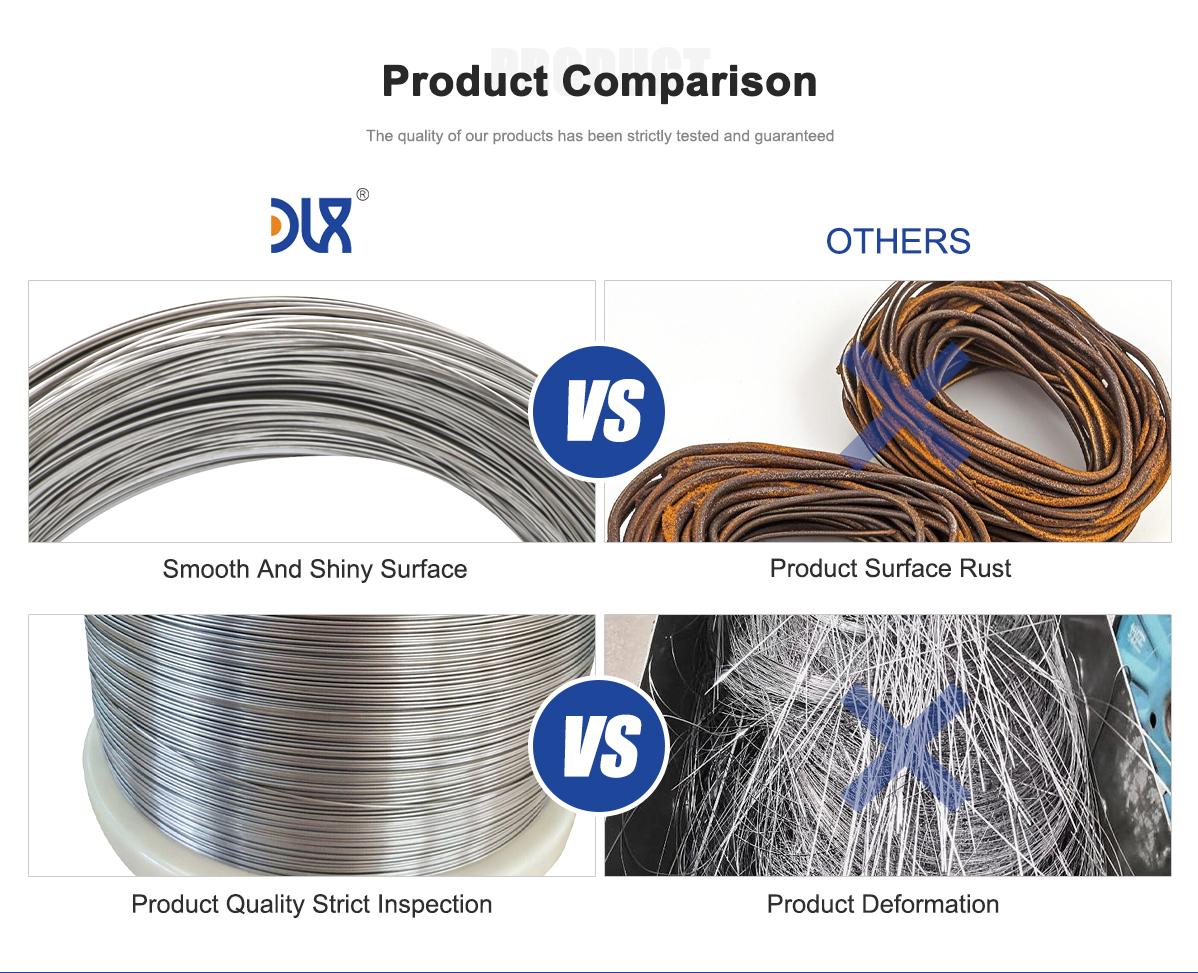

Facing off with alloy hustlers, DLX doesn't follow; we lead with Nimonic 90 that's smarter, quicker, tougher. Some pump out inconsistent stuff – inclusions sparking failures or diameters drifting, ruining your winds. Us? Vacuum-induction plus ultrasonic scans nail ±0.005mm tolerances – flawless every spool. Leads? They drag 10-14 weeks; we ship stock 3-5, customs 7, via in-house draws.

Tailoring? Masterclass – adjust Co for creep tweaks or Zr for grains, all AS9100/ISO stamped, not generic slop. Costs? 15-20% slimmer sans quality cuts, from efficient runs and sourcing – margins stay fat. Real results: 35% better creep in field tests vs. norms, purer chem and anneals paying off. Eco lead: 60% recycled now, aiming 75% by '27, lapping 30% stragglers. Support? Teams with FEA for designs – not dump-and-run. In cutthroat markets, DLX flips reliability to your advantage.

Quick Specs: Nimonic 90 Table Showdown

Here's DLX Nimonic 90 vs. standard Ni-Cr and Inconel 718 – see it crush on heat creep.

| Parameter | DLX Nimonic 90 | Standard Ni-Cr Alloy | Inconel 718 |

|---|---|---|---|

| Composition (Key %) | Ni 54+, Cr 18-21, Co 15-21, Ti 2-3, Al 1-2 | Ni 80, Cr 20 | Ni 50-55, Cr 17-21, Nb 4.75-5.5, Mo 2.8-3.3 |

| Yield Strength (MPa, Aged) | 750 | 200-400 | 1035 |

| Tensile Strength (MPa) | 1200 | 600-800 | 1275 |

| Max Service Temp (°C) | 920 | 1150 (short) | 700 |

| Creep Rupture (1000h @ 815°C, MPa) | 200-300 | 50-100 | 150-250 |

| Oxidation Resistance | Superior to 920°C | Good to 1100°C | Excellent to 980°C |

| Weldability | Fair (preheat needed) | Excellent | Good (less cracking) |

| Density (g/cm³) | 8.18 | 8.30 | 8.19 |

| Cost Relative | Baseline | 65-75% | 180-220% |

Nimonic 90 owns high-heat endurance, topping Inconel on temp limits. Reach out for customs.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We hear these daily – here's the no-BS answers.

Aging perks for Nimonic 90? Hardens precipitates for 3x yield boost, locking strength at 800°C for turbine discs without snap risks.

Corrosion hold-up? Bosses oxidation and hot corrosion; alumina-chromia layer shines in sulfur gases, but protect in wet acids.

Weld tricks? TIG with fillers, preheat 200°C, post-age – cracks low if clean and controlled.

Fatigue rating? Hits 10^7 cycles at 600 MPa, precipitate toughening ideal for vibrating blades.

Cold performance? Stays ductile to -200°C, good toughness for hybrid cryo-heat apps.

Machining tips? Hardens some; carbide at 20 m/min, heavy coolant – smoother than Nb alloys.

Green creds? 90% recyclable, our low-emission melts meet aero sustainability goals.

DLX sizes and ships? 0.05-5mm, spools/straights; 3-5 weeks stock, 7 customs – quicker than most.

Final Take: Amp Up with DLX Nimonic 90

Wrapping it – Nimonic 90 wire decoded, from elements to exploding markets. At DLX, we're forging wins with alloy that tackles infernos, fueling aero and energy futures. Our quality, hustle, and brains give you the upper hand – jump in, build fierce.