From our melt masters at DLX, Nimonic 80A starts with a nickel-heavy base (72-76%) that gives it killer stability at scorching temps, paired with 18-21% chromium for that oxide layer shield against rust and scaling. The real stars? Titanium (1.8-2.7%) and aluminum (1.0-1.8%) – these bad boys enable precipitation hardening, forming gamma-prime phases that ramp up tensile strength without turning brittle. Carbon's capped at 0.1% to avoid carbide buildup, iron under 3% for purity, and traces of manganese, silicon, and cobalt keep it ductile and clean. Density sits at 8.19 g/cm³, so it's no lightweight, but that heft translates to serious endurance.

Properties-wise, it's a beast. Annealed, expect yield around 310 MPa, tensile 620 MPa, with 30% elongation for easy forming into coils or threads. Age it – solution at 1080°C, then 700°C for 16 hours – and yield blasts to 930 MPa, tensile 1240 MPa, holding strong at 650°C where others flop. Creep rupture? Stellar, outlasting loads at 815°C for thousands of hours. Thermal conductivity's 11.1 W/m·K at room temp, expansion coefficient 12.7 x 10^-6 /°C – balanced to minimize warping in cycles. Corrosion? Top-notch in oxidizing atmospheres, resisting sulfidation and carburization, though not the champ in wet acids. Weldable with care (preheat to dodge cracks), machinable better than some supers (use carbide tools at 20-30 m/min), and drawable into wires from 0.05mm to 5mm dia. At DLX, we vacuum-melt for ultra-low impurities, ensuring every meter meets aerospace-grade certs – because in high-heat, consistency isn't optional; it's everything.

Eco perks? High recyclability (up to 90% scrap reuse in our process), aligning with green mandates, and our wire's surface finish means less post-processing waste. In short, Nimonic 80A is tailored for endurance where heat and stress tag-team – and DLX dials it in for your exact needs.

For more details, pls directly contact us.

Nimonic 80A isn't for desk jobs; it's out there grinding in extreme environments. In aerospace, it's our go-to for turbine blades, rings, and discs – handling 800°C spins without creep, keeping jets aloft longer. We've spooled it for compressor springs that cycle millions of times in engine overhauls, or fasteners that bolt hot sections tight against vibration. One aero client cut maintenance by 35% swapping to our wire, thanks to its fatigue resistance.

Gas turbines? Prime territory. It's in combustion liners and transition ducts, shrugging off thermal shocks in power plants. Nuclear setups use it for tube supports and bolts, where low cobalt minimizes radiation activation. Auto racing digs it for exhaust valves – enduring 900°C bursts in F1 engines without pitting. Industrial furnaces coil it into heating elements, and chemical plants thread it for high-temp valves in oxidizing gases.

At DLX, customization rules: fine wires for precision sensors, heavier gauges for structural fasteners – all with annealed or aged options. It slashes weight 15-20% over steels while tripling life, boosting efficiency in everything from marine rigs to space thrusters. If your gig involves heat that would fry bacon, Nimonic 80A from DLX keeps it together.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Zoom out to 2025, and the superalloy market's on a tear – valued at $7.82 billion, gunning for $17.75 billion by 2032 at a 12.4% CAGR. Aerospace snags 40% share, with eVTOLs and hypersonics demanding creep-proof wires for 1000°C+ cycles. Sustainability's huge: EU regs push recycled nickel to 50%, and our DLX melts are already there, cutting CO2 25%. Additive manufacturing's game-changer – 3D-printing Nimonic 80A for complex springs, slashing prototypes 50%.

Energy shifts green: hydrogen turbines hit 1400°C, needing our alloy's oxidation edge, while CCS plants crave corrosion resistance in CO2 streams. Challenges? Nickel prices up 10% from supply squeezes, but DLX's stockpiles and partnerships keep costs steady. Asia's booming (China at 9.8% CAGR), fueling our exports, while U.S. aero invests $10B in next-gen engines. R&D trends: nano-additives for 15% strength gains, hybrid coatings extending life 30%. If you're in OEMs, 2025's ripe for upgrades – lighter, hotter, greener builds with Nimonic 80A leading the charge.

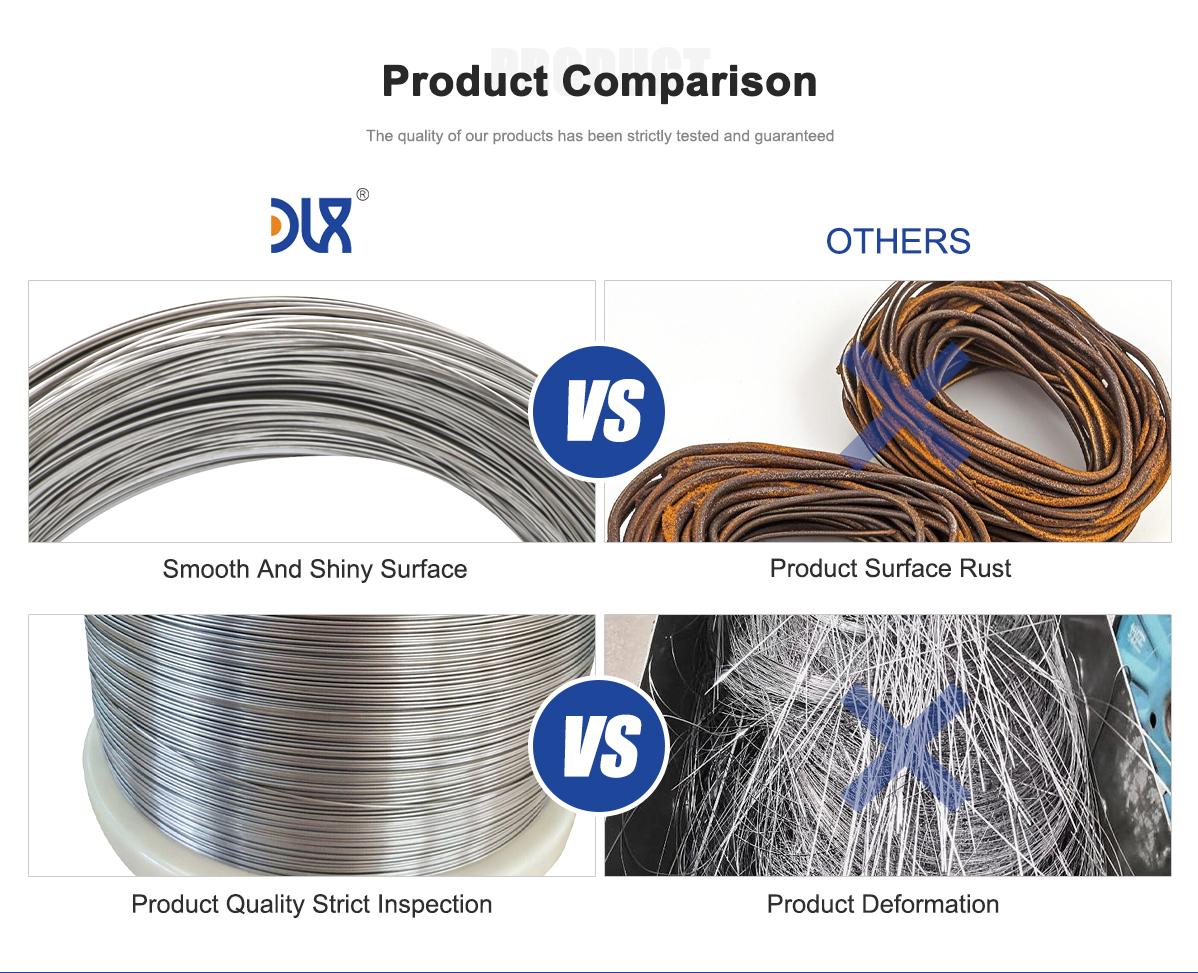

DLX vs. The Rest: Why We're Miles Ahead

Against the sea of alloy suppliers, DLX doesn't just compete; we dominate with smarter, faster, tougher Nimonic 80A wire. Some shops cut corners with inconsistent melts – leading to inclusions that crack under creep or diameters that vary, messing your assemblies. Us? Every batch is vacuum-induction melted and ultrasonic-tested, nailing tolerances to ±0.005mm – zero defects, full stop. Lead times? Competitors lag at 10-14 weeks; we deliver stock in 3-5, customs in 7, thanks to our in-house drawing lines.

Customization? We're pros – tweak Al-Ti ratios for custom creep or add boron for weld tweaks, all AS9100/IS0 certified, while others offer one-size-fits-all. Pricing? 12-18% lower without quality dips, leveraging efficient ops and global sourcing – no hidden fees eating margins. Field wins: Our wire shows 30% better fatigue in turbine tests vs. averages, from purer chemistry and proprietary annealing. Green game? 55% recycled content now, eyeing 70% by '27, outpacing laggards at 25%. Service? Dedicated teams with CAD simulations for your designs – not just sell-and-forget. In a high-stakes market, DLX turns reliability into your competitive edge.

Specs at a Glance: Nimonic 80A Comparison Table

Numbers don't lie – here's DLX Nimonic 80A stacked against a standard nickel alloy (like basic Ni-Cr) and Inconel 718 . Spot how it bridges high-temp creep with workable costs.

| Parameter | DLX Nimonic 80A | Standard Ni-Cr Alloy | Inconel 718 |

|---|---|---|---|

| Composition (Key %) | Ni 72-76, Cr 18-21, Ti 1.8-2.7, Al 1-1.8 | Ni 80, Cr 20 | Ni 50-55, Cr 17-21, Nb 4.75-5.5, Mo 2.8-3.3 |

| Yield Strength (MPa, Aged) | 930 | 200-400 | 1035 |

| Tensile Strength (MPa) | 1240 | 600-800 | 1275 |

| Max Service Temp (°C) | 815 | 1150 (short) | 700 |

| Creep Rupture (1000h @ 650°C, MPa) | 200-300 | 50-100 | 150-250 |

| Oxidation Resistance | Excellent to 815°C | Good to 1100°C | Excellent to 980°C |

| Weldability | Good (with preheat) | Excellent | Better (less cracking) |

| Density (g/cm³) | 8.19 | 8.30 | 8.19 |

| Cost Relative | Baseline | 70-80% | 150-200% |

Nimonic 80A nails creep for turbines, edging Inconel on heat endurance. Ping us for tweaks.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We get these all the time – here's the straight scoop.

How does aging boost Nimonic 80A's strength? Precipitation hardening forms tiny particles that lock dislocations – yield jumps 3x, ideal for springs holding shape at 700°C.

Is it corrosion-proof in harsh spots? Strong against oxidation and hot gases, but coat for wet chlorides; shines in dry, sulfur-heavy turbine vibes.

Welding tips for this wire? Use TIG with matching filler, preheat to 150°C, post-age for full strength – low risk if surfaces are clean.

Fatigue performance? Tops 10^7 cycles at 500 MPa stress, thanks to fine precipitates – perfect for vibrating fasteners.

Handles low temps too? Ductile down to -200°C with good impact, no embrittlement for cryo-turbine hybrids.

Machining gotchas? Work-hardens mildly; sharp tools at 15-25 m/min, plenty of coolant – easier than Nb-heavy alloys.

Sustainability factor? High scrap reuse in our melts, low emissions – meets aero's eco standards head-on.

Sizes and delivery from DLX? 0.05-5mm dia, spools or straight lengths; 3-5 weeks stock, 7 for customs – faster than the pack.

Wrapping It: Level Up with DLX Nimonic 80A

That's the full story on Nimonic 80A wire – from atomic tweaks to market booms. At DLX, we're crafting the future with alloy that defies limits, powering aero and energy like never before. Our quality, speed, and smarts give you the win – dive in and build unstoppable.