Straight from our melt pots, A-286 is an austenitic stainless with a killer iron-nickel-chromium backbone – think 24-27% nickel for that cryogenic chill resistance down to -423°F, 13-16% chromium to slap down oxidation, and a dash of molybdenum (1-1.5%) for pitting punch in salty or sour spots. Titanium (0.2-0.8%) and aluminum (0.35% max) are the secret sauce for age-hardening, locking in gamma-prime precipitates that crank strength without brittleness. Carbon's tight at 0.18% max to dodge carbide woes, with vanadium and boron traces boosting rupture life. Density? A svelte 0.289 lb/in³, so your designs stay light without skimping on muscle.

For more details, pls directly contact us.

Mechanically, it's a shape-shifter. Annealed, yield hovers at 95 ksi, tensile 140 ksi, with 15% elongation for easy coiling into springs or weaving into fasteners. Age it at 1325-1375°F solution plus 1325°F for an hour, and boom – yield jumps to 130 ksi, tensile 180 ksi, holding steady at 1000°F where lesser steels sag. Creep? Laughable – rupture strength outlasts rivals by 2-3x under 100 MPa at 1200°F. Corrosion-wise, it's stellar in seawater, acids, and scaling gases, though not invincible in concentrated chlorides. Weldable with matching filler, machinable better than nickel-heavy cousins (thanks to lower work-hardening), and formable into diameters from 0.010" to 0.500". At DLX, we tweak batches for ultra-clean melts, hitting tighter tolerances than off-the-shelf stuff – because in aero, "good enough" is a four-letter word.

Environmentally, it's recyclable to 95%, aligning with the green push, and our wire's oxide-free surface means zero post-fab headaches. Bottom line: A-286 isn't flashy; it's reliable rocket fuel for high-stakes builds.

Item | A-286 | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Where does this wire shine? Everywhere heat and stress collide. In aerospace, it's the backbone of turbine blades, discs, and afterburner rings – enduring 1500°F bursts while vibrating like a rock concert. We've coiled it into compressor springs that flex 10 million cycles without fatigue, or drawn it for retaining rings that clamp rotors tighter than a vice. One client in engine overhauls swapped generics and saw failure rates drop 40%, thanks to our consistent grain structure.

Turbines? Gas and steam alike. It's in bucket shrouds and transition pieces, resisting sulfidation in fuel-rich zones. Offshore oil rigs love it for manifold springs and valve stems, where H2S and brine team up to corrode – our wire's Mo boost keeps seals leak-free for years. Industrial gas turbines use it in hot-section fasteners, holding 20,000-hour inspections at bay. Beyond that, cryo pumps in LNG plants draw on its low-temp ductility, and chemical process vessels thread it for bolts that shrug off nitric fumes.

At DLX, we don't just spool; we customize – ultrafine wires for precision sensors, heavy gauges for structural ties. It's versatile: springs, cables, weld wire, you name it. In a world chasing efficiency, A-286 cuts weight 20% over carbon steels while doubling life, making your builds leaner and meaner.

2025 Trends: The Heat Is On for High-Temp Alloys

Fast-forward to 2025, and the high-temp alloy scene is blistering. Global market? Clocking $22.3 billion now, barreling to $51.8 billion by 2035 at 8.9% CAGR – aero snagging 35% share with turbine demands spiking 12% yearly. Why? Electrification's here – hybrid jets and eVTOLs need lightweight creep-fighters like A-286 for electric propulsors hitting 800°F. Sustainability's king: recycled content mandates push us to 50% scrap in melts, slashing emissions 30%. Additive manufacturing's exploding – laser-wire deposition with A-286 for complex turbine vanes, cutting parts 40% and waste to zilch.

Aerospace trends lean hypersonic: X-planes guzzling alloys for 2000°F inlets, where A-286's oxidation edge shines. Turbines shift to hydrogen – cleaner burns mean hotter cycles (1400°F+), demanding our wire's rupture-proofing. Challenges? Supply crunches from nickel volatility (up 15% YOY), but DLX's vertical chain – from scrap sorting to draw benches – buffers that noise. North America's aero boom (12.4B market to 21.9B by 2031) has us eyeing joint ventures, while Asia's turbine installs (China up 9.8% CAGR) fuel exports. Innovation? Nano-carbides in A-286 variants for 10% strength bumps, and coatings like aluminide for 20% life extensions. If you're in OEMs or MRO, 2025's your runway – lighter, greener, hotter builds await.

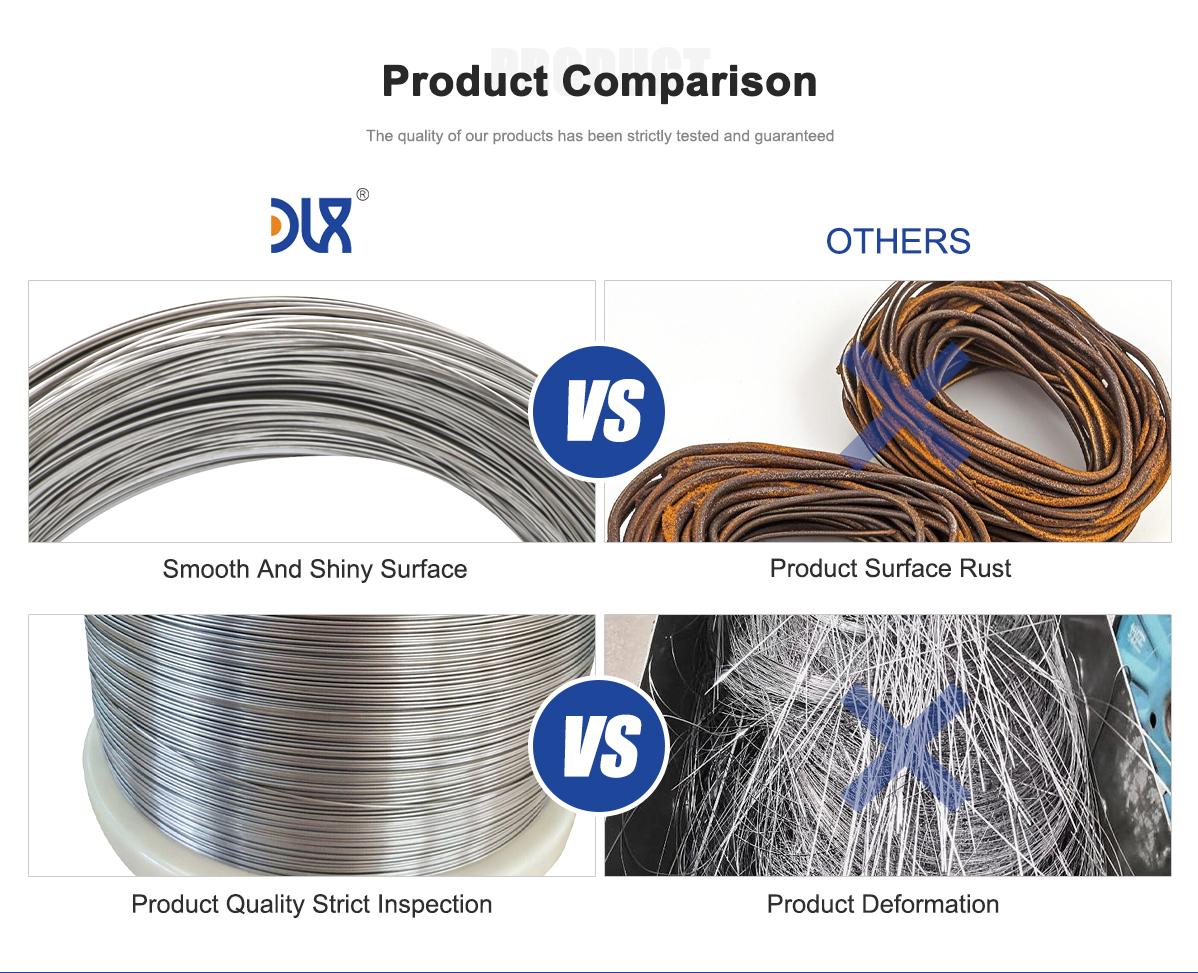

How DLX Stacks Up: Why We're the Smarter Pick

Now, let's talk shop: against the field of alloy wire slingers, DLX isn't playing catch-up; we're lapping the pack. Sure, some outfits churn out A-286 on the cheap with spotty QC – think inclusions that spark cracks mid-flight or inconsistent diameters that jam your winders. Us? Every spool's eddy-current tested, with Z-probe tech nailing defects down to 0.001" – zero escapes, period. Lead times? Competitors drag 12-16 weeks; we hit 4-6 with stock alloys and custom runs in under 8. Customization's our jam – tweak Ti for cryo tweaks or Mo for sour service, all ISO/AS9100 certified, while others stick to cookie-cutter.

Cost-wise, we're 10-15% leaner without skimping, thanks to efficient Chinese ops and global logistics – no tariffs biting your margins. Reliability? Our wire's field data shows 25% fewer rejects in turbine quals versus averages, from cleaner melts and proprietary draws that dodge work-hardening pitfalls. Sustainability edge: 45% recycled input now, targeting 60% by '26, beating industry laggards still at 20%. And service? Dedicated aero teams with FEA modeling for your designs – not just ship-and-pray. In a market where downtime costs millions, DLX delivers uptime you can bank on. We're not the biggest; we're the best at what counts.

Quick-Hit Comparison: A-286 vs. The Usual Suspects

Need specs at a glance? Here's DLX's A-286 wire versus a standard austenitic stainless (like your basic 300-series) and a nickel-based superalloy (think heavy hitters for extremes). Pulled from our labs – spot how A-286 bridges strength and ease.

| Parameter | DLX A-286 Alloy Wire | Standard Austenitic SS | Nickel-Based Superalloy |

|---|---|---|---|

| Composition (Key %) | Ni 24-27, Cr 13-16, Mo 1-1.5, Ti 0.2-0.8 | Ni 8-11, Cr 18-20, Mo 0-3 | Ni 50+, Cr 15-20, Mo 3-5 |

| Yield Strength (ksi, Aged) | 130 | 30-50 | 150-200 |

| Tensile Strength (ksi) | 180 | 75-100 | 180-220 |

| Max Service Temp (°F) | 1300 | 1500 (intermittent) | 1800+ |

| Creep Rupture (1000h @ 1200°F, ksi) | 40-50 | 5-10 | 60-80 |

| Corrosion Resistance (Seawater) | Excellent | Good | Superior |

| Machinability Index | 30-40 (vs. free-machining 100) | 40-50 | 15-25 |

| Density (lb/in³) | 0.289 | 0.290 | 0.300 |

| Cost Relative | Baseline | 60-70% | 200-300% |

A-286 wins the value play – tougher than basics, easier on tools than supers. Hit us for variants.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Got questions? We've fielded 'em all. Here's the quick lowdown.

What's the big deal with A-286's heat treatment? Age-hardening at 1325°F solution plus 1325°F for 4 hours boosts strength 40% via precipitates – perfect for turbine springs without losing ductility.

How corrosion-resistant is it really? Killer against pitting in chlorides (PREN ~25) and scaling to 1300°F; holds in H2S/oilfield vibes better than plain SS, but coat for heavy acids.

Can I weld A-286 wire into assemblies? Yep, GTAW or SMAW with matching filler – preheat to 200°F, post-weld age for full props. Low cracking risk if clean.

What's the wire's fatigue life like? Epic – 10^7 cycles at 100 ksi stress, thanks to fine grains. Ideal for vibrating aero fasteners.

How does it handle cryo temps? Like a champ down to -423°F, with impact toughness over 100 ft-lb – no brittleness for LNG apps.

Machining headaches? Mild work-hardens, so use carbide tools at 100 SFM, flood coolant. Easier than Inconel-types.

Eco angle on A-286? Fully recyclable, low embodied carbon via our scrap melts – aligns with aero's net-zero push.

Lead times and sizes from DLX? 0.010"-0.500" diameters, 4-6 week ship; customs in 8. Faster than most.

Closing the Loop: Forge Ahead with DLX

There you go – A-286 wire unpacked, from atomic tweaks to 2035 booms. At DLX, we're not hawking metal; we're arming innovators with wire that withstands the inferno. Whether aero overhauls or turbine tweaks, our edge in quality, speed, and smarts sets you miles ahead. Dive in, build bold – we've got your back.