Our GH3625 high-strength alloy wire is a beast when it comes to tackling tough industrial environments. This nickel-chromium-molybdenum superalloy is engineered for exceptional strength, corrosion resistance, and stability up to 1800°F (982°C). Cold-drawn and heat-treated for maximum durability, it’s designed to handle extreme stress and harsh conditions without breaking a sweat. From chemical plants to aerospace components, our GH3625 wire is built to perform where others can’t.

For more details, pls directly contact us.

We’ve crafted our GH3625 wire to meet stringent standards like AMS 5666 and GB/T 14992, making it a top choice for industries facing extreme conditions. Its high tensile strength, excellent fatigue resistance, and superior corrosion resistance make it perfect for critical applications. Plus, it’s easy to fabricate, saving you time and effort during production. Whether it’s for high-pressure valves or turbine parts, our wire delivers consistent, reliable performance.

Industry Analysis

The high-strength alloy wire market is on a hot streak, with a projected CAGR of 5.6% through 2033, reaching USD 3.8 billion. Aerospace, chemical processing, and energy sectors are driving demand for materials that can withstand harsh environments, high temperatures, and corrosive conditions. The growth of green energy systems and advanced manufacturing is pushing the need for durable alloys, though challenges like raw material price volatility and strict regulations remain. We stay ahead with innovative production and sustainable practices, ensuring our GH3625 wire meets both performance and environmental standards.

|

Item |

Nimonic80A |

Nimonic 90 |

GH1140 |

GH3625 |

GH3536 |

GH4169 |

|

|

C |

≤0.08 |

≤0.1 |

≤0.13 |

0.06-0.12 |

≤0.1 |

0.05-0.15 |

≤0.08 |

|

Mn |

≤2 |

≤1 |

≤1 |

≤0.7 |

3.14-4.15 |

-- |

≤0.35 |

|

Fe |

rest |

≤3 |

≤1.5 |

rest |

≤0.5 |

-- |

rest |

|

P |

≤0.04 |

≤0.02 |

-- |

≤0.025 |

-- |

-- |

-- |

|

S |

≤0.03 |

≤0.015 |

≤0.015 |

≤0.015 |

-- |

-- |

≤0.01 |

|

Si |

≤1 |

≤1 |

≤1 |

≤0.8 |

-- |

-- |

≤0.35 |

|

Cu |

-- |

-- |

≤0.2 |

-- |

-- |

-- |

≤0.3 |

|

Ni |

24-27 |

rest |

-- |

35-40 |

rest |

rest |

50-55 |

|

Co |

-- |

≤2 |

15-21 |

-- |

≤1.00 |

0.5-2.5 |

≤1.00 |

|

Al |

≤0.35 |

1-1.8 |

1-2 |

0.2-0.6 |

≤0.4 |

≤0.5 |

0.2-0.8 |

|

Ti |

1.9-2.35 |

1.8-2.7 |

2-3 |

0.7-1.2 |

≤0.4 |

≤0.15 |

0.7-1.15 |

|

Cr |

13.5-16 |

18-21 |

18-21 |

20-23 |

20-23 |

20.5-23 |

17-21 |

|

Nb |

-- |

-- |

-- |

-- |

-- |

-- |

4.75-5.5 |

|

Mo |

1-1.5 |

-- |

-- |

2-2.5 |

8-10 |

8-10 |

2.8-3.3 |

|

B |

0.001-0.1 |

≤0.008 |

≤0.02 |

-- |

-- |

-- |

-- |

|

V |

0.1-0.5 |

-- |

-- |

-- |

-- |

-- |

-- |

|

W |

-- |

-- |

-- |

1.4-1.8 |

-- |

0.2-1 |

-- |

|

Zr |

-- |

≤0.15 |

≤0.15 |

-- |

-- |

-- |

-- |

|

Pb |

-- |

-- |

≤0.002 |

-- |

-- |

-- |

-- |

|

Ce |

-- |

-- |

-- |

≤0.05 |

-- |

-- |

-- |

|

Size Range |

|

|

Wire |

0.5-7.5mm |

|

Rod/Bar |

8.0-200mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Tube |

custom made |

| Plate | custom made |

For more details, pls directly contact us.

Our GH3625 alloy wire thrives in the toughest settings. In aerospace, it’s used for turbine blades, fasteners, and structural components, handling extreme heat and stress. In chemical processing, it’s ideal for valves, pumps, and piping systems exposed to corrosive fluids. The energy sector relies on it for gas turbines and heat exchangers, while its strength and durability make it perfect for marine and oil & gas applications. From high-pressure industrial systems to cryogenic environments, this wire gets the job done.

Comparison with Other Materials

Here’s how our GH3625 wire compares to other high-strength materials:

|

Parameter |

GH3625 Wire |

Nickel-Chromium Alloys |

Stainless Steel |

Titanium Alloys |

|---|---|---|---|---|

|

Max Temperature (°F) |

1800 |

1800 |

1200 |

1100 |

|

Corrosion Resistance |

Excellent |

Excellent |

Moderate |

High |

|

Tensile Strength (ksi) |

140-160 |

120-140 |

80-100 |

120-140 |

|

Fatigue Resistance |

Excellent |

Good |

Moderate |

Good |

|

Fabrication Ease |

High |

Moderate |

High |

Moderate |

|

Cost Efficiency |

Moderate |

High |

Low |

High |

|

Cryogenic Performance |

Excellent (-320°F) |

Good |

Poor |

Moderate |

|

Applications |

Aerospace, chemical, energy |

Aerospace, chemical processing |

General industrial |

Aerospace, medical |

Our GH3625 wire offers a killer combo of strength, corrosion resistance, and versatility, making it a standout for demanding applications.

Our Company’s Advantages

We’re all about pushing the limits of what’s possible. Our GH3625 alloy wire is produced with cutting-edge cold-drawing and heat-treatment processes, ensuring top-notch strength and reliability. We meet the highest industry standards while keeping costs in check, delivering value without compromise. Our R&D team is always innovating, creating wires that perform better and last longer. With global distribution centers, we ensure fast delivery across the U.S., Europe, and Asia. Our eco-friendly production methods also reduce our environmental footprint while maintaining superior quality.

About Us:

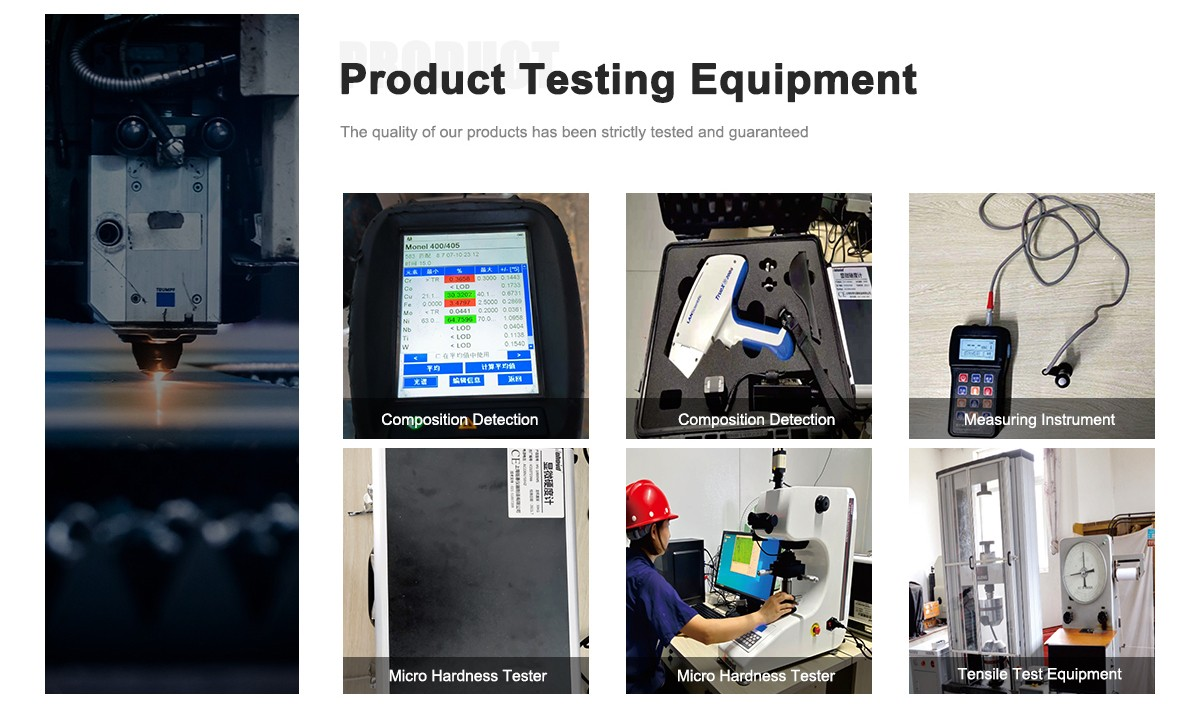

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What makes GH3625 wire suitable for harsh industrial conditions?

Its nickel-chromium-molybdenum composition provides excellent strength and corrosion resistance up to 1800°F. -

Which industries use GH3625 wire?

Aerospace, chemical processing, energy, and marine, especially for turbines, valves, and piping systems. -

How does GH3625 compare to nickel-chromium alloys?

It offers similar corrosion resistance but higher tensile strength and better fatigue performance. -

Can GH3625 wire handle cryogenic conditions?

Yes, it maintains strength and toughness down to -320°F. -

What standards does your GH3625 wire meet?

It complies with AMS 5666, GB/T 14992, and other high-performance specifications. -

Is GH3625 wire easy to fabricate?

Absolutely, its high ductility makes it ideal for complex component manufacturing. -

How do you ensure the quality of GH3625 wire?

We use advanced testing, like ultrasonic inspection, and strict quality controls to meet industry standards. -

What’s driving demand for GH3625 wire?

Growth in aerospace, green energy, and chemical processing, plus the need for durable, corrosion-resistant materials.

Why We Stand Out

Our GH3625 high-strength alloy wire is built to conquer the toughest challenges in aerospace, chemical processing, and energy applications. With a focus on quality, innovation, and sustainability, we deliver solutions that perform under pressure. Whether it’s a turbine blade or a high-pressure valve, our wire offers unmatched strength and reliability, backed by a global supply chain that ensures you get what you need, when you need it.