Laboratories and research facilities rely on precision, stability, and reliability when it comes to high-temperature equipment. Among the various alloys available for heating systems, Cr10Ni90 Nichrome Strip stands out as one of the most advanced options. With its exceptionally high nickel content and balanced chromium ratio, this alloy delivers superior thermal stability, resistance consistency, and performance in demanding laboratory environments. At DLX, we provide Cr10Ni90 Nichrome Strip engineered for precision and long-term reliability, making it a trusted material in high-end research and testing systems worldwide.

For more details, pls directly contact us.

Cr10Ni90 is composed of approximately 10% chromium and 90% nickel, with minor additions of iron and other trace elements. This high nickel content provides outstanding oxidation resistance and stability at elevated temperatures. Unlike standard nichrome alloys, Cr10Ni90 maintains its structural integrity and resistance value over extended heating cycles, even when operated at the upper temperature limits of laboratory furnaces.

The alloy is designed to offer:

-

Consistent electrical resistance with minimal drift

-

Oxidation resistance in controlled and oxidizing atmospheres

-

High mechanical stability to prevent warping or deformation

-

Long operational lifespan under continuous high-temperature exposure

|

Performance / material |

Cr10Ni90 |

Cr20Ni80 |

Cr30Ni70 |

Cr20Ni35 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

In modern laboratories, accuracy and repeatability are non-negotiable. Cr10Ni90 Nichrome Strip is a preferred material in high-temperature laboratory equipment such as:

-

Laboratory furnaces for materials testing

-

Controlled atmosphere heating systems

-

Tube furnaces and crucible heaters

-

Research-grade ceramic and glass processing units

-

Analytical instruments requiring thermal precision

Because of its resistance stability, Cr10Ni90 ensures that experimental setups can run for long durations without fluctuations in heat output. This makes it invaluable in sensitive experiments where consistency is crucial.

Industry Trends and Demand

The demand for Cr10Ni90 Nichrome Strip is being driven by two major trends: the rise of advanced materials research and the growing importance of laboratory automation. As research institutions and industries push boundaries in ceramics, composites, and electronics, the need for reliable high-temperature heating solutions has intensified.

Laboratories are also moving toward automation and continuous operation, which requires materials with minimal maintenance requirements. Cr10Ni90 Nichrome Strip, with its extended service life and reduced oxidation rates, aligns perfectly with these industry shifts. Additionally, global investments in R&D across energy, semiconductors, and advanced materials are further driving the adoption of premium nichrome alloys.

Comparing Cr10Ni90 with Other Nichrome Grades

Different nichrome grades are used across industries, but Cr10Ni90 is unique in its specialization for laboratory and precision applications. Compared with Cr20Ni80, Cr10Ni90 offers even higher nickel content, giving it slightly improved oxidation resistance and thermal stability.

While Cr15Ni60 and Cr20Ni30 are strong choices for general heating applications in ceramics or metallurgy, they do not match the resistance consistency of Cr10Ni90 under precision conditions. Cr30Ni70 is excellent for chemical processing, but again, it lacks the extreme resistance stability required for research applications.

This makes Cr10Ni90 the preferred choice where accuracy, repeatability, and long-term stability are priorities.

DLX Manufacturing Advantage

At DLX, we don’t just supply materials—we engineer solutions for high-performance industries. Our Cr10Ni90 Nichrome Strip is manufactured with tight dimensional tolerances, ensuring precise width and thickness that directly translates to predictable resistance values. We understand that laboratory applications often require customized formats, so we offer a wide range of sizes, coils, and tailored specifications.

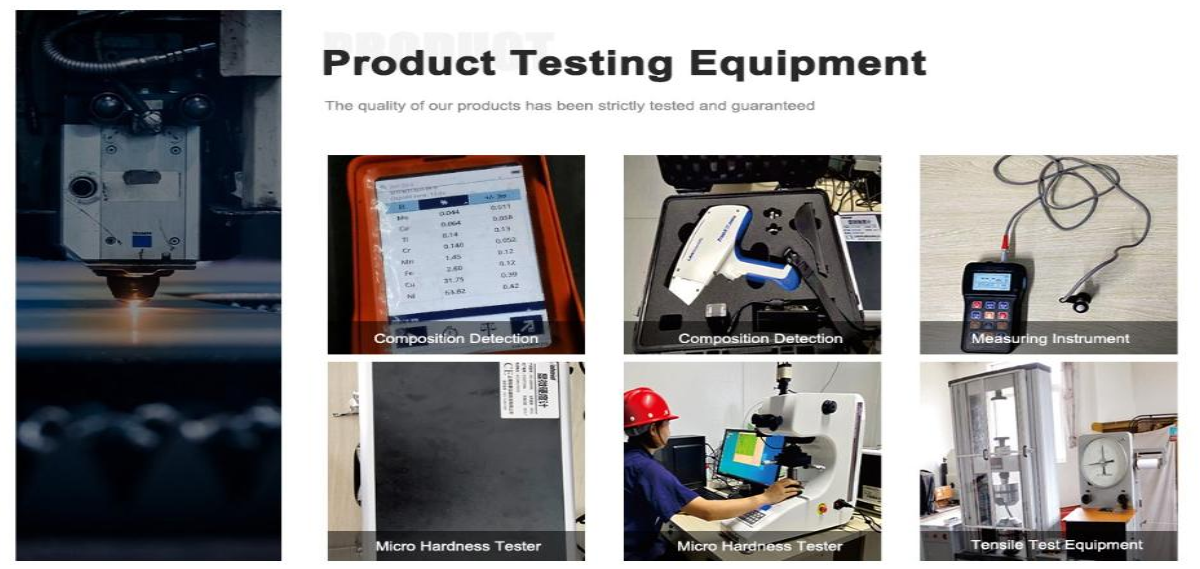

Quality assurance is central to our process. Every batch of Cr10Ni90 Nichrome Strip undergoes strict inspection to guarantee uniformity and consistency. Our clients in the laboratory and research sectors value not just the product but also the reliability of our supply chain. DLX has built a reputation for on-time delivery, technical guidance, and post-sale support that helps customers integrate our materials seamlessly into their systems.

Comparison Table

| Grade | Composition (Cr/Ni, %) | Max Service Temp (°C) | Key Features | Typical Applications |

|---|---|---|---|---|

| Cr15Ni60 | Cr 15 / Ni 60 | 1150 | Balanced strength, oxidation resistance | Marine, industrial heating elements |

| Cr20Ni30 | Cr 20 / Ni 30 | 1100–1150 | Strong mechanical stability | Kilns, ceramic processing, metallurgy |

| Cr20Ni35 | Cr 20 / Ni 35 | 1150 | Good corrosion and resistance stability | Precision resistors, circuits |

| Cr20Ni80 | Cr 20 / Ni 80 | 1200 | High-temperature durability, long service life | Custom heating designs, furnace components |

| Cr10Ni90 | Cr 10 / Ni 90 | 1200–1250 | Superior resistance stability, lab precision | Laboratory furnaces, controlled heating systems |

Although Cr10Ni90 is primarily associated with laboratory heating systems, its high nickel content also makes it suitable for specialized industrial applications. These include aerospace testing equipment, semiconductor processing, and high-precision resistance components. Wherever stability and reliability are critical, this alloy proves its worth.

The global push for innovation in science and technology will only increase the reliance on high-performance heating materials. As laboratories evolve with more advanced testing equipment, alloys like Cr10Ni90 will remain in high demand. Its role in supporting research and development across energy, aerospace, electronics, and materials science ensures a steady market growth trajectory.

Why DLX for Cr10Ni90 Nichrome Strip

What sets DLX apart is our ability to deliver more than a product. We work closely with research institutions and industrial clients to provide materials that align with specific operational goals. Our expertise in high-temperature alloys means we can advise on the best grade for each unique application.

With a focus on quality, customization, and service, DLX has become a trusted partner for laboratories worldwide. Our Cr10Ni90 Nichrome Strip is not just a raw material—it is a critical component that helps ensure reliable, repeatable, and accurate results in laboratory operations.

Cr10Ni90 Nichrome Strip is a premium alloy designed for precision and reliability in high-temperature laboratory heating systems. Its exceptional nickel content delivers unmatched stability, making it a trusted material for research and advanced testing applications. As laboratories and research facilities continue to demand more from their heating equipment, DLX stands ready to supply the materials that make consistent results possible.

With our focus on quality, technical expertise, and customer-driven service, DLX is the ideal partner for laboratories seeking high-performance Cr10Ni90 Nichrome Strip.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is the composition of Cr10Ni90 Nichrome Strip?

It contains approximately 10% chromium and 90% nickel, with iron and trace elements as balance. -

What is the maximum service temperature of Cr10Ni90 Nichrome Strip?

It can withstand continuous operation up to around 1200–1250°C. -

Why is Cr10Ni90 suitable for laboratory heating systems?

It provides exceptional stability, consistent resistance, and minimal drift during repeated heating cycles. -

Can Cr10Ni90 Nichrome Strip be used in precision instruments?

Yes, its resistance uniformity and thermal stability make it ideal for lab furnaces, heaters, and controlled experiments. -

What are the common dimensions for Cr10Ni90 Nichrome Strip?

Typical thickness ranges from 0.05 mm to 2 mm, and widths can be customized between 5 mm and 300 mm. -

Is Cr10Ni90 corrosion resistant?

Yes, it has excellent oxidation resistance at high temperatures, especially in laboratory and controlled atmospheres. -

How does Cr10Ni90 compare with Cr20Ni80?

Cr10Ni90 offers higher nickel content, which means better thermal stability and slightly higher temperature resistance. -

Why choose DLX for Cr10Ni90 Nichrome Strip?

DLX provides precision manufacturing, reliable supply, technical expertise, and customization options tailored to laboratory and research industries.