In industrial processes where heat, consistency, and durability are central, the choice of materials becomes a critical factor in overall performance. For heat treatment and annealing operations, Cr30Ni70 Nichrome Strip has established itself as a premium alloy solution. At DLX, we deliver high-quality Cr30Ni70 Nichrome Strip designed for industries that demand reliability in high-temperature and oxidation-prone environments.

For more details, pls directly contact us.

Cr30Ni70 is composed of roughly 30% chromium and 70% nickel, a formulation that gives it excellent resistance to oxidation and scaling at elevated temperatures. The high chromium content contributes to chemical resistance, while the nickel ensures thermal stability and mechanical integrity. This balance makes the alloy well-suited for repeated thermal cycling in heat treatment and annealing processes.

The strip retains its shape and strength even during long-term exposure to high temperatures, preventing warping or premature failure. With stable electrical resistance and strong creep resistance, it delivers consistent results over time.

|

Performance / material |

Cr20Ni80 |

Cr30Ni70 |

Cr15Ni60 |

Cr20Ni35 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Heat treatment processes—such as hardening, tempering, and annealing—require materials that can handle sustained exposure to elevated temperatures without degrading. Cr30Ni70 Nichrome Strip is commonly used in:

-

Heating elements for annealing furnaces

-

Heat treatment fixtures and support structures

-

Industrial furnace components requiring chemical resistance

-

Metallurgical processing where high precision is necessary

In annealing operations, where metals are softened and internal stresses relieved, uniform heating is crucial. Cr30Ni70 Nichrome Strip ensures stable resistance, enabling controlled and consistent heating cycles. This translates to higher product quality and fewer defects in the treated materials.

Industry Trends Driving Demand

Global demand for advanced heat treatment and annealing continues to grow across industries such as automotive, aerospace, and metallurgy. As companies pursue stronger, lighter, and more durable materials, the importance of precise heat treatment has become central to production.

With the push toward energy efficiency and sustainability, furnaces and heating systems are increasingly designed for longer service lives and reduced downtime. Materials like Cr30Ni70 Nichrome Strip are aligned with these trends, as their durability and resistance properties lower the frequency of replacements.

Another driver is the rise in demand for specialty steels and alloys, which require precise and repeatable annealing and heat treatment cycles. Cr30Ni70 plays a role in ensuring these processes remain efficient and reliable.

Different nichrome grades are chosen based on the specific balance of cost, strength, and resistance needed. Compared with Cr20Ni80, Cr30Ni70 provides enhanced chemical and oxidation resistance, making it particularly valuable in environments with aggressive atmospheres.

While Cr15Ni60 is often used in marine environments, and Cr20Ni30 excels in kiln and ceramic applications, Cr30Ni70 finds its best fit in heat treatment and annealing where both chemical resistance and thermal stability are needed. It offers a good balance between high resistance consistency and durability at high temperatures.

Comparison Table

| Grade | Composition (Cr/Ni, %) | Max Service Temp (°C) | Key Features | Typical Applications |

|---|---|---|---|---|

| Cr15Ni60 | Cr 15 / Ni 60 | 1150 | Balanced oxidation resistance, ductility | Marine-grade resistance, heating elements |

| Cr20Ni30 | Cr 20 / Ni 30 | 1100–1150 | Strong mechanical stability | Kilns, ceramic processing, metallurgy |

| Cr20Ni35 | Cr 20 / Ni 35 | 1150 | Resistance stability, good corrosion strength | Precision resistors, electrical circuits |

| Cr20Ni80 | Cr 20 / Ni 80 | 1200 | High-temperature durability, long lifespan | Custom heating designs, furnace components |

| Cr30Ni70 | Cr 30 / Ni 70 | 1200 | Superior chemical and oxidation resistance | Heat treatment, annealing, industrial furnaces |

At DLX, we go beyond simply supplying alloy strips. Our approach focuses on precision, quality, and service. Each batch of Cr30Ni70 Nichrome Strip is manufactured under strict quality control, ensuring accurate composition and uniform dimensions. This consistency guarantees predictable performance in industrial furnaces, where even slight variations can affect results.

We understand that every customer has different requirements. That’s why we offer customization in terms of thickness, width, and coil sizes. Whether for a small-scale application or large industrial system, DLX provides solutions tailored to your operational needs.

Another key advantage of choosing DLX is our technical expertise. Our team works closely with customers to recommend the right alloy grade and dimensions based on specific processes, ensuring efficiency and performance. Coupled with our reliable delivery network, DLX offers a seamless experience from order to application.

Performance Benefits for Industry

The durability of Cr30Ni70 Nichrome Strip means reduced downtime and maintenance costs. In industries where production schedules are tight and efficiency is critical, fewer disruptions translate to real savings. The alloy’s stability during long-term service ensures consistent heating performance, which in turn helps deliver uniform product quality.

Moreover, its superior oxidation resistance makes it especially valuable in environments where other alloys might degrade more quickly. This advantage is particularly relevant in continuous annealing operations, where the strip’s longevity becomes a key asset.

The global heat treatment industry is expected to expand steadily, driven by innovation in metallurgy, automotive lightweighting, and advanced material manufacturing. With these developments, demand for reliable high-temperature alloys like Cr30Ni70 Nichrome Strip will remain strong.

At DLX, we are committed to supporting this growth by offering materials that combine technical excellence with practical value. Our Cr30Ni70 Nichrome Strip not only meets today’s requirements but is also positioned to adapt to the evolving demands of future industrial processes.

Cr30Ni70 Nichrome Strip is a high-performance material built for the rigors of industrial heat treatment and annealing. With its combination of high nickel and chromium, it delivers superior oxidation resistance, strength, and stability under extreme conditions.

At DLX, we provide Cr30Ni70 Nichrome Strip with a focus on precision, customization, and reliability. By choosing our products, industries gain not just a material but a partner dedicated to helping them achieve efficiency, consistency, and long-term performance in their critical heat treatment operations.

About Us:

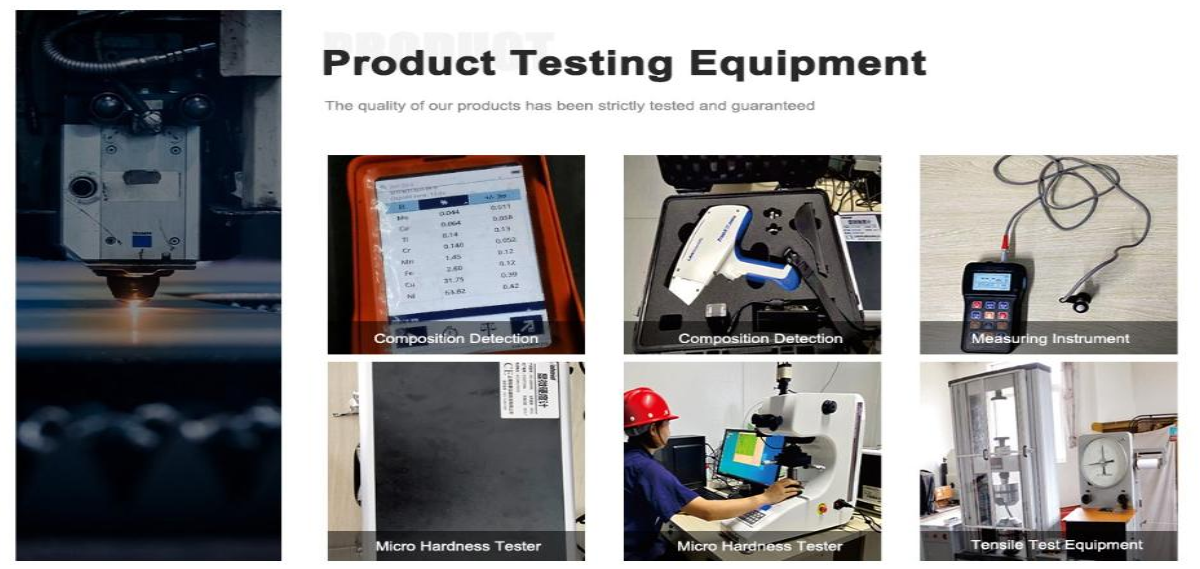

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is the composition of Cr30Ni70 Nichrome Strip?

It contains approximately 30% chromium and 70% nickel, with iron and trace elements. -

What is the maximum operating temperature of Cr30Ni70 Nichrome Strip?

It can typically withstand continuous service up to around 1200°C. -

What industries use Cr30Ni70 Nichrome Strip?

It is widely applied in heat treatment, annealing furnaces, metallurgical processes, and industrial heating systems. -

How does Cr30Ni70 perform in oxidation-prone environments?

It has excellent oxidation resistance and retains stability in high-temperature atmospheres. -

Can Cr30Ni70 Nichrome Strip be customized in dimensions?

Yes, DLX offers various thicknesses, widths, and coil sizes according to client needs. -

What are the mechanical benefits of Cr30Ni70 Nichrome Strip?

It maintains high strength, good creep resistance, and dimensional stability during prolonged heating. -

How does Cr30Ni70 compare to Cr20Ni80 Nichrome?

Cr30Ni70 offers enhanced chemical resistance, while Cr20Ni80 has slightly higher thermal stability. -

Why choose DLX for Cr30Ni70 Nichrome Strip?

DLX provides precision processing, consistent quality, reliable delivery, and technical support for heat treatment applications.