When it comes to the demanding conditions of kilns, ceramic processing lines, and other high-temperature industrial equipment, one material consistently stands out: Cr20Ni30 Nichrome Strip. This alloy combines strength, resistance stability, and reliability in environments where extreme heat and oxidative stress are the norm. At DLX, we focus on delivering high-performance Cr20Ni30 Nichrome Strip that not only meets technical requirements but also enhances the efficiency and lifespan of your industrial systems.

For more details, pls directly contact us.

The Cr20Ni30 alloy is composed of approximately 20% chromium and 30% nickel, with iron making up the balance. This carefully engineered ratio gives the strip a strong combination of properties: excellent oxidation resistance at high temperatures, consistent resistivity, and mechanical strength even after long-term exposure to harsh furnace atmospheres.

Unlike higher-nickel nichrome grades, Cr20Ni30 finds its niche in applications where both mechanical stability and cost-effectiveness are important. It is a preferred option in industries like ceramics and metallurgy, where the thermal cycles are constant, and materials are expected to withstand repeated heating and cooling without losing performance.

|

Performance / material |

Cr20Ni80 |

Cr15Ni60 |

Cr20Ni30 |

||||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

In ceramic manufacturing, kilns are the heart of production. They operate at sustained high temperatures, often exceeding 1100°C, and require heating elements that can endure without frequent replacement. Cr20Ni30 Nichrome Strip is a reliable choice for kiln linings, resistance elements, and components in ceramic sintering equipment.

The alloy's strength helps maintain dimensional stability during prolonged heating, reducing warping and deformation. This stability directly translates into better process control and more consistent product quality for manufacturers. Additionally, its resistance to oxidation prevents scaling, which otherwise shortens the life of furnace parts.

In metallurgy, Cr20Ni30 is widely used in resistance elements, industrial furnaces, and heat treatment equipment. Its combination of oxidation resistance and mechanical integrity ensures consistent performance, even under heavy-duty cycles.

Industry Trends

The demand for Cr20Ni30 Nichrome Strip is closely tied to growth in ceramics, advanced materials, and metallurgical industries. As energy efficiency becomes a central focus, kiln and furnace operators are prioritizing materials that extend service life and minimize downtime. Nichrome strips like Cr20Ni30 are increasingly seen as investments in operational reliability.

Global ceramics production, from tiles and refractories to electronic ceramics, continues to rise. The shift toward automation and high-precision production is also pushing demand for materials that deliver predictable performance under stress. Meanwhile, the metallurgical industry relies on alloys like Cr20Ni30 for annealing, sintering, and forging processes that cannot compromise on heat resistance.

Why DLX Cr20Ni30 Nichrome Strip

At DLX, we understand that performance at high temperatures is only one part of the equation. Industrial users also need consistency, precise tolerances, and supply reliability. Our Cr20Ni30 Nichrome Strip is manufactured under strict process controls, ensuring stable resistivity and dimensional accuracy.

We provide customization across thickness, width, and coil formats, giving customers flexibility to integrate the strip into various systems. With years of experience in alloy production, we also offer technical support to help clients choose the right grade for their specific applications.

Unlike many general suppliers, we maintain a strong focus on niche high-temperature alloys. This specialization means our team understands the real challenges faced by ceramic processors, kiln operators, and metallurgical plants, and we can provide solutions that go beyond simply delivering raw materials.

Comparison Table

| Grade | Composition (Cr/Ni, %) | Max Service Temp (°C) | Main Features | Typical Applications |

|---|---|---|---|---|

| Cr15Ni60 | Cr 15 / Ni 60 | 1150 | Excellent oxidation resistance, ductile | Marine resistance, heating elements |

| Cr20Ni30 | Cr 20 / Ni 30 | 1100–1150 | High strength, stable resistance | Kilns, ceramic processing, metallurgy |

| Cr20Ni35 | Cr 20 / Ni 35 | 1150 | Balanced mechanical and corrosion properties | Precision resistors, electrical circuits |

| Cr20Ni80 | Cr 20 / Ni 80 | 1200 | Superior thermal stability, long lifespan | Custom heating designs, furnace elements |

| Cr30Ni70 | Cr 30 / Ni 70 | 1200+ | Enhanced chemical resistance | Chemical equipment, reactors, high-temp heaters |

While Cr20Ni80 and Cr30Ni70 are often chosen for extremely high-temperature or chemical environments, Cr20Ni30 offers a balance of performance and economy. It provides excellent resistance stability for kiln and ceramic applications without the higher material cost associated with high-nickel alloys. This makes it an ideal choice for manufacturers seeking durability without overspending.

Compared to Cr15Ni60, Cr20Ni30 provides slightly higher strength and a broader operating window in furnace environments. Compared to Cr20Ni35, it is more cost-effective while still maintaining excellent mechanical stability.

As industries continue to scale up production and adopt smarter manufacturing systems, the role of reliable heating materials will only grow. Nichrome strips like Cr20Ni30 are not only enabling higher output but also reducing maintenance downtime. With global infrastructure development and technological advancements in ceramics and metallurgy, demand for this alloy is set to rise steadily.

We position ourselves as more than a supplier—we are a partner. By offering customized solutions, on-time delivery, and technical expertise, DLX ensures that our clients receive materials that integrate seamlessly into their operations. Our investment in quality control and process optimization also means lower defect rates and higher reliability for end users.

For kiln and ceramic processing companies aiming for long-term performance, Cr20Ni30 Nichrome Strip from DLX provides a strong foundation. With proven resistance stability, high mechanical strength, and our dedicated service, we help businesses achieve consistency, efficiency, and reliability in their production cycles.

In short, Cr20Ni30 Nichrome Strip represents a balance of performance, strength, and value. At DLX, we are committed to making this alloy a key enabler of high-temperature industrial success.

About Us:

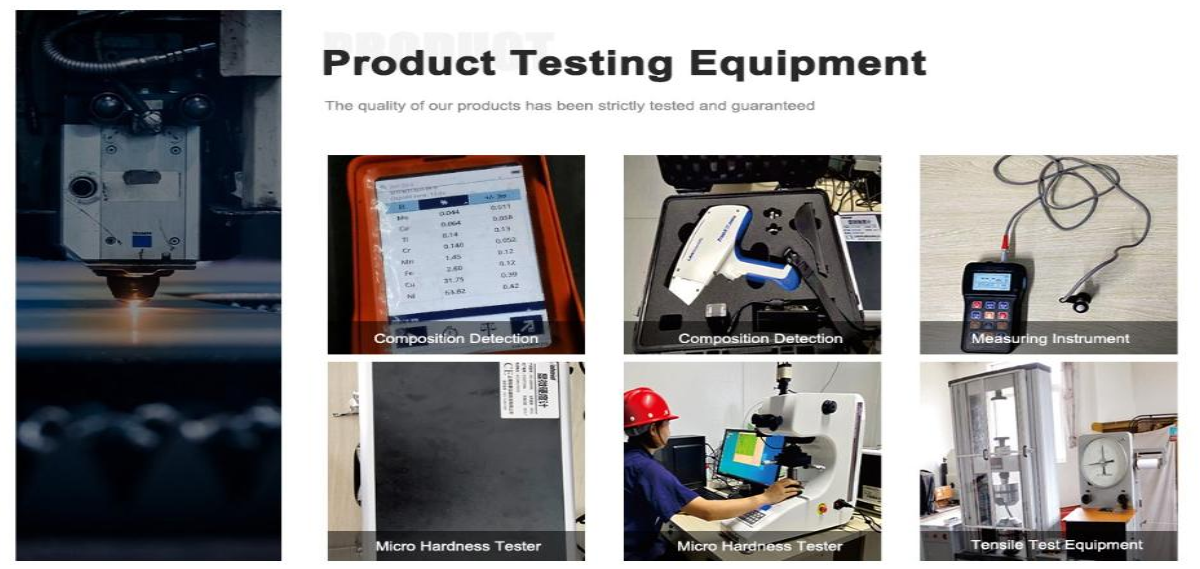

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is the composition of Cr20Ni30 Nichrome Strip?

It contains approximately 20% chromium, 30% nickel, and the balance iron with trace elements. -

What industries mainly use Cr20Ni30 Nichrome Strip?

It is widely used in kiln equipment, ceramic processing, metallurgy, and industrial furnaces. -

How does Cr20Ni30 Nichrome Strip perform at high temperatures?

It offers strong oxidation resistance, stable electrical resistance, and high mechanical strength at elevated temperatures. -

Can Cr20Ni30 Nichrome Strip be customized into coils and sheets?

Yes, it can be supplied in strip, sheet, wire, or coil form depending on customer requirements. -

What is the maximum operating temperature of Cr20Ni30 Nichrome Strip?

It can typically withstand continuous service up to 1100–1150°C. -

Is Cr20Ni30 Nichrome Strip corrosion resistant in oxidizing environments?

Yes, it is specifically designed to perform well in oxidizing and high-temperature atmospheres. -

What are the common thickness and width ranges for Cr20Ni30 Nichrome Strip?

Thickness usually ranges from 0.05 mm to 3 mm, and width from 5 mm to 300 mm. -

Why choose DLX for Cr20Ni30 Nichrome Strip?

DLX provides consistent quality, precise tolerances, reliable delivery, and technical support tailored to industrial applications.