Cr10Ni90 Nichrome wire, a high-performance alloy made of 90% nickel and 10% chromium, is one of our flagship products designed for extreme environments. Known for its low electrical resistance, rapid heat generation, and exceptional corrosion resistance, this wire is a game-changer in aerospace applications. It’s built to withstand temperatures up to 1200°C (2200°F) while maintaining durability and stability, making it perfect for demanding tasks where reliability is non-negotiable. Our Cr10Ni90 wire is crafted with precision, offering consistent performance, high tensile strength, and resistance to oxidation, ensuring it meets the rigorous standards of aerospace engineering.

The aerospace industry is booming, driven by the push for lightweight, fuel-efficient aircraft and advancements in space exploration. According to market insights, the demand for high-performance materials like nickel-chromium alloys is growing at a steady clip, with a projected CAGR of over 5% through 2030. This growth is fueled by the need for components that can handle extreme temperatures and corrosive environments, especially in jet engines, de-icing systems, and sensor applications. Sustainability is also a big deal—our Cr10Ni90 wire’s energy efficiency aligns with the industry’s shift toward greener, cost-effective solutions. As aerospace companies innovate, materials like ours are becoming critical to staying ahead in a competitive market.

Applications of Cr10Ni90 Nichrome Wire

Our Cr10Ni90 wire shines in aerospace but isn’t limited to it. Here’s where it makes an impact:

-

Aerospace Components: Used in de-icing systems for aircraft wings and engine parts, ensuring safety and performance at high altitudes.

-

Temperature Sensors: Its stable resistance makes it ideal for precise temperature monitoring in harsh conditions.

-

Heating Elements: Powers industrial furnaces and high-tech equipment with consistent, rapid heating.

-

Electronic Systems: Perfect for resistors and voltage regulators in aerospace electronics, delivering reliable performance.

-

Specialized Applications: From 3D printing to laboratory flame testing, its versatility supports cutting-edge projects.

Comparison with Other Materials

To help you understand why Cr10Ni90 stands out, here’s a quick comparison with other common materials:

|

Parameter |

Cr10Ni90 Nichrome |

Kanthal (FeCrAl) |

Copper |

Stainless Steel |

|---|---|---|---|---|

|

Max Operating Temp (°C) |

1200 |

1400 |

200 |

800 |

|

Electrical Resistivity (μΩ·m) |

1.0-1.1 |

1.35-1.45 |

0.017 |

0.7-0.8 |

|

Corrosion Resistance |

Excellent |

Good |

Poor |

Moderate |

|

Tensile Strength (MPa) |

650-800 |

600-700 |

200-400 |

500-700 |

|

Oxidation Resistance |

High (Cr oxide layer) |

High |

Low |

Moderate |

|

Density (g/cm³) |

8.4 |

7.1 |

8.9 |

7.8 |

|

Cost Efficiency |

High |

Moderate |

High |

Moderate |

|

Aerospace Suitability |

Excellent |

Good |

Limited |

Moderate |

Cr10Ni90’s lower resistivity and superior corrosion resistance make it a top pick for aerospace, where efficiency and durability are critical. Unlike copper, it thrives in high-heat environments, and compared to stainless steel, it offers better oxidation resistance. Kanthal holds up at higher temps but lacks the same level of corrosion resistance and versatility.

|

Performance / material |

Cr10Ni90 |

Cr20Ni80 |

Cr30Ni70 |

Cr20Ni30 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Our Cr10Ni90 Nichrome wire is engineered with a focus on quality and innovation. We use high-purity nickel and chromium, ensuring every batch meets strict aerospace standards. Our advanced manufacturing process guarantees uniform composition and consistent performance, reducing downtime and maintenance costs for our clients. We also prioritize sustainability—our wire’s energy-efficient design helps lower operational costs, aligning with the aerospace industry’s eco-conscious trends. With decades of expertise and a commitment to customization, we deliver tailored solutions that fit your exact needs, whether it’s for a jet engine or a precision sensor. Plus, our global supply chain ensures fast delivery, so you’re never left waiting.

Why Choose Us for Your Aerospace Needs?

Our Cr10Ni90 Nichrome wire isn’t just a product—it’s a solution built for the future of aerospace. Its unmatched durability, efficiency, and versatility make it a go-to for engineers tackling the toughest challenges. Whether you’re designing next-gen aircraft or pushing the boundaries of space exploration, our wire delivers the performance you need. Ready to elevate your project? Let’s talk about how our Cr10Ni90 can make it happen.

About Us:

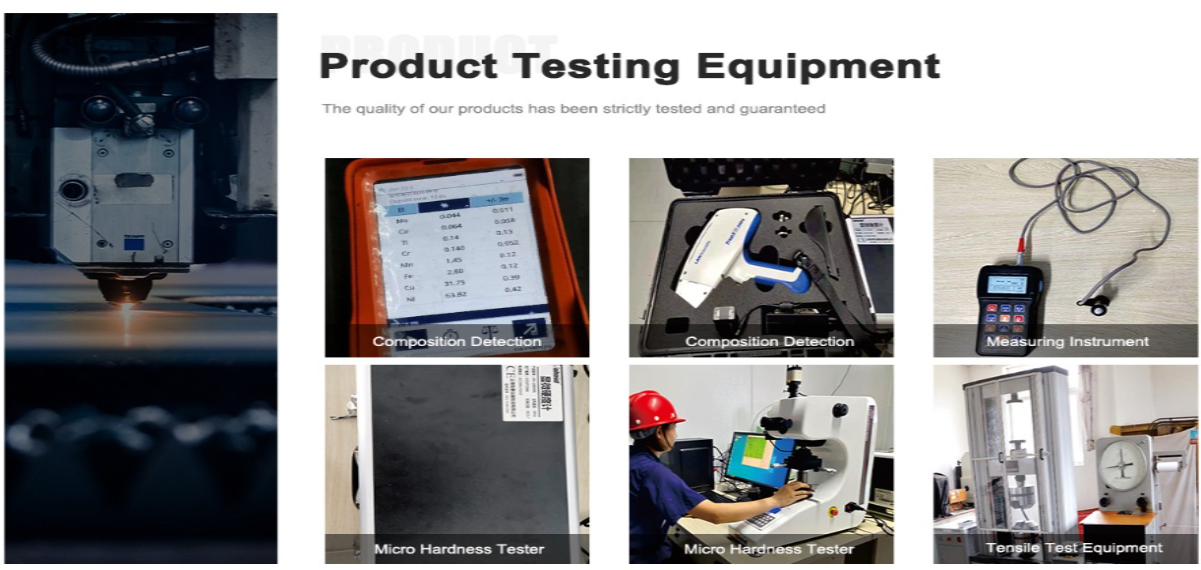

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What makes Cr10Ni90 Nichrome wire ideal for aerospace?

Its high corrosion resistance, rapid heat generation, and ability to withstand temperatures up to 1200°C make it perfect for de-icing systems and engine components. -

How does Cr10Ni90 compare to other Nichrome alloys?

With 90% nickel, it has lower electrical resistance than Ni80Cr20, making it more energy-efficient for aerospace applications. -

Can Cr10Ni90 be used in non-aerospace applications?

Absolutely, it’s versatile enough for industrial heaters, 3D printing, and laboratory equipment. -

How does your Cr10Ni90 wire ensure reliability?

We use high-purity materials and advanced manufacturing to ensure consistent performance and durability. -

What’s the max temperature Cr10Ni90 can handle?

It performs reliably up to 1200°C (2200°F) without losing strength or oxidizing. -

Is Cr10Ni90 environmentally friendly?

Its low electrical resistance reduces energy consumption, aligning with sustainable aerospace trends. -

How does your company support custom orders?

We offer tailored gauges and compositions to meet specific project requirements, backed by our expertise. -

Why choose your Cr10Ni90 over competitors?

Our focus on quality, customization, and fast delivery sets us apart, ensuring top performance for your aerospace needs.