Our Cr20Ni30 Nichrome wire is a dependable nickel-chromium alloy built for reliable heating in toasters and household appliances. With 20% chromium and 30% nickel, balanced with iron, this wire delivers solid corrosion resistance and steady performance at temperatures up to 1050°C (1922°F). Its melting point hovers around 1380°C (2516°F), making it a great fit for applications needing consistent heat without burnout. The low-to-moderate resistivity ensures efficient energy use, perfect for compact, high-performance appliances.

Available in diameters from 0.015’’ to 0.25’’, our Cr20Ni30 wire comes in spools, coils, or custom cuts to match your manufacturing needs. Its flexibility and ease of shaping make it a breeze to integrate into tight designs, whether you’re crafting heating elements or small resistors. We’ve designed this wire to keep your appliances running smoothly with minimal maintenance.

Industry Analysis

The nichrome wire market is buzzing, driven by the booming home appliance sector and growing demand for compact, energy-efficient heating solutions. As consumers lean toward smart, durable appliances, materials like Cr20Ni30 are in high demand for their reliability and cost-effectiveness. The rise of IoT-enabled appliances and eco-conscious manufacturing is pushing the industry toward materials that offer long lifespans and reduced energy consumption. Market growth is projected to stay strong through 2030, especially in regions with expanding consumer electronics markets.

Sustainability is a key trend, with manufacturers seeking alloys that last longer and reduce waste. Our Cr20Ni30 Nichrome wire aligns with these priorities, offering durability and efficiency that meet modern appliance standards while keeping production costs in check.

Comparison Table

|

Parameter |

Cr20Ni30 Nichrome Wire |

Other Nichrome Alloys |

|---|---|---|

|

Composition |

30% Ni, 20% Cr, Fe |

Varies (e.g., 60% Ni, 15% Cr) |

|

Max Operating Temperature |

1050°C (1922°F) |

1000–1150°C (1832–2102°F) |

|

Melting Point |

1380°C (2516°F) |

1350–1400°C (2462–2552°F) |

|

Resistivity |

1.03 μΩ·m |

1.04–1.20 μΩ·m |

|

Corrosion Resistance |

Very good (oxide layer) |

Moderate to good |

|

Service Life |

Up to 4-5 years |

3-5 years |

|

Workability |

Excellent (flexible) |

Moderate |

|

Customization Options |

Wide range (spools, coils) |

Limited |

Our Cr20Ni30 Nichrome wire is a star performer in various applications:

-

Toasters and Grills: Powers heating elements for fast, even toasting and grilling.

-

Home Appliances: Used in hair dryers, space heaters, and electric kettles for reliable heating.

-

Small Electronics: Supports low-power resistors and circuit components.

-

Food Preparation: Found in slow cookers and air fryers for consistent temperature control.

-

HVAC Systems: Enables small-scale heating units for efficient climate control.

-

DIY Repairs: Ideal for fixing or upgrading heating elements in household devices.

Its corrosion resistance and moderate resistivity make it a top choice for compact, high-efficiency heating needs.

|

Performance / material |

Cr30Ni70 |

Cr15Ni60 |

Cr20Ni35 |

Cr20Ni30 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Our Cr20Ni30 Nichrome wire stands tall against other alloys. While some alternatives may struggle with corrosion or inconsistent heating, our wire offers excellent oxidation resistance and a service life of up to 4-5 years in appliance applications. Its superior workability allows for easy integration into intricate designs, saving you time during production. We also provide customizable diameters and packaging options, from small spools to bulk coils, giving you more options than many competitors.

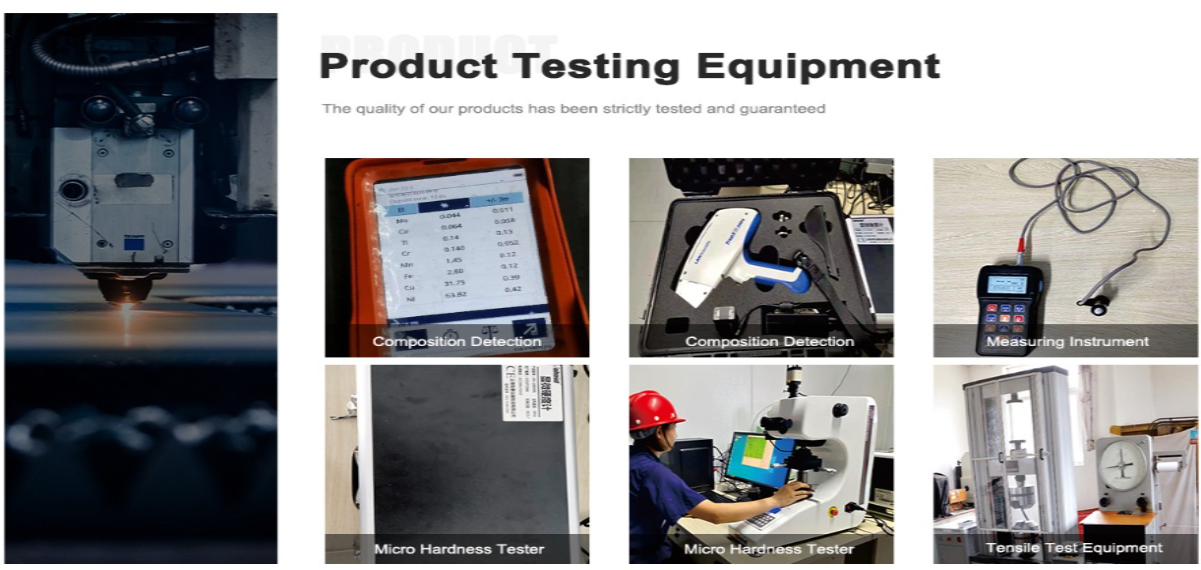

Every batch meets ASTM B344 standards, ensuring reliable performance you can trust. Our efficient production process keeps costs low without sacrificing quality, making our wire a budget-friendly choice for manufacturers and repair shops alike.

Why Choose Our Cr20Ni30 Nichrome Wire?

We’ve crafted our Cr20Ni30 Nichrome wire to deliver top-notch reliability for your appliance heating needs. Its corrosion resistance and stable resistivity mean fewer replacements and lower energy costs, keeping your products running longer. The wire’s flexibility and weldability make it easy to work with, even in compact designs. With our focus on quality control and customization, you’re getting a product tailored to your specs and built to last. Whether you’re manufacturing toasters or repairing heaters, our wire ensures efficiency and durability every time.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Cr20Ni30 Nichrome wire made of?

It’s a nickel-chromium alloy with 30% nickel, 20% chromium, and iron for corrosion resistance and strength. -

What are the main applications of Cr20Ni30 Nichrome wire?

It’s used in toasters, home appliances, small electronics, food prep devices, HVAC systems, and DIY repairs. -

What temperatures can Cr20Ni30 Nichrome wire handle?

It performs reliably up to 1050°C (1922°F) with a melting point of about 1380°C (2516°F). -

Is Cr20Ni30 Nichrome wire corrosion-resistant?

Yes, its chromium content forms a protective oxide layer to resist corrosion in humid or chemical environments. -

Can the wire be customized?

Definitely, we offer diameters from 0.015’’ to 0.25’’, plus spools, coils, or custom cuts for your needs. -

How long does Cr20Ni30 Nichrome wire last?

In appliance applications, it lasts 4-5 years, depending on usage and conditions. -

Is Cr20Ni30 Nichrome wire easy to work with?

Yes, it’s flexible and easy to shape, making it perfect for intricate appliance designs. -

What industries benefit most from Cr20Ni30 Nichrome wire?

Home appliance manufacturing, electronics, food prep, HVAC, and DIY repair sectors rely on its performance.