Our Custom Diameter Nimonic 90 Spring Wire for Extreme Heat Applications is designed to tackle the toughest thermal challenges in industries where heat pushes materials to their limits. This isn't just another superalloy wire; it's a precision-engineered solution that combines the inherent strengths of Nimonic 90 with our ability to customize diameters for perfect fit and performance. If you're looking for high-temperature spring wire or Nimonic 90 alloy wire that can handle extreme heat without breaking a sweat, we've got you covered with a product that delivers reliability and efficiency in the hottest environments.

Let's dive into what makes this spring wire special. Built from a nickel-based superalloy, our Nimonic 90 contains 54-62% nickel for a rock-solid base that thrives in high heat, 18-21% chromium for top-notch oxidation and corrosion resistance, and 15-21% cobalt to boost strength. Add in 2-3% titanium and 1-2% aluminum for precipitation hardening, and you get a material that laughs off creep even at 920°C. We take it up a notch with a manufacturing process that starts with vacuum induction melting to keep impurities at bay, followed by hot rolling and precision cold drawing to hit exact diameters from 0.05mm to 12mm. Our age-hardening step fine-tunes the microstructure, ensuring creep resistance and tensile strength (1300-1500 MPa at room temp) that outperform standard options. The custom diameter feature is a game-changer—whether you need ultra-fine wire for delicate aerospace springs or thicker coils for industrial furnaces, we tailor it to your specs, reducing waste and ensuring optimal force delivery. Plus, we offer coatings for extra oxidation protection, keeping your components pristine in scorching conditions. This wire is built for extreme heat applications, delivering consistent elasticity and fatigue life where others might warp or crack.

For more details, pls directly contact us.

Looking at the industry landscape in 2025, the superalloy sector is red-hot, driven by demands for materials that can handle escalating temperatures in cutting-edge applications. The market for nickel-based alloys like Nimonic 90 is growing at over 5% annually, fueled by advancements in aerospace, renewable energy, and high-performance automotive sectors. Aerospace is pushing for hotter, more efficient jet engines to cut fuel consumption, with turbines now operating at temperatures that demand superior creep resistance. Renewable energy is another big player—concentrated solar power and geothermal plants rely on alloys that can endure intense heat cycles without deforming. We're also seeing a boom in additive manufacturing, with 3D printing techniques like powder bed fusion creating complex Nimonic 90 parts, cutting production time and material waste. Sustainability is a major trend, with companies recycling alloys to offset nickel and cobalt supply chain risks, aligning with global net-zero goals by 2050. Challenges like raw material price spikes are being tackled through innovations in alloy synthesis and closed-loop recycling systems. Petrochemical industries are leaning on high-temperature alloys for safer, more efficient refining processes under stricter emissions rules. Our Custom Diameter Nimonic 90 Spring Wire fits perfectly into this landscape, offering the flexibility and durability needed to meet these evolving demands while supporting eco-conscious manufacturing.

Applications for our Nimonic 90 spring wire are as diverse as the industries it serves. In aerospace, it’s a go-to for gas turbine engines, forming springs in combustors, turbine blades, and afterburners that must resist creep and thermal fatigue at temperatures pushing 920°C. These components face relentless heat and vibration, and our wire ensures they stay reliable, boosting engine efficiency and lifespan. Power generation is another key area—think gas and steam turbines where springs in valve assemblies and seals need to maintain integrity under high-pressure, high-heat conditions. In renewable energy, our wire shines in solar thermal plants, supporting tracking systems and heat exchanger springs that endure constant thermal cycling. Petrochemical plants use it in reactors and furnaces, where it handles extreme heat alongside corrosive gases, keeping operations smooth. High-performance automotive applications, like turbocharged engines, rely on it for valve springs that resist softening in scorching exhaust systems. Even in space exploration, this wire supports rocket engine components, where low thermal expansion and high strength are critical. The custom diameter option makes it versatile—whether you’re crafting micro-springs for precision actuators or robust coils for heavy-duty fasteners, we deliver wire that fits your design perfectly, optimizing performance in extreme heat applications.

| Parameter | Details |

|---|---|

| Grade | Nimonic 90 |

| Material Type | Nickel-Chromium-Cobalt Alloy |

| UNS Number | N07090 |

| Standard Specifications | ASTM B637, BS HR2, ISO 9723 |

| Main Characteristics | High strength, excellent creep resistance, oxidation resistance up to 950°C |

| Typical Applications | Springs, turbine blades, fasteners, gas turbine components |

| Chemical Composition (Typical, %) | |

| Nickel (Ni) | Balance (~58%) |

| Chromium (Cr) | 18.0 – 21.0 |

| Cobalt (Co) | 15.0 – 21.0 |

| Titanium (Ti) | 2.0 – 3.0 |

| Iron (Fe) | ≤ 3.0 |

| Aluminum (Al) | 1.0 – 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | ≤ 0.2 |

| Carbon (C) | ≤ 0.13 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.02 |

For more details, pls directly contact us.

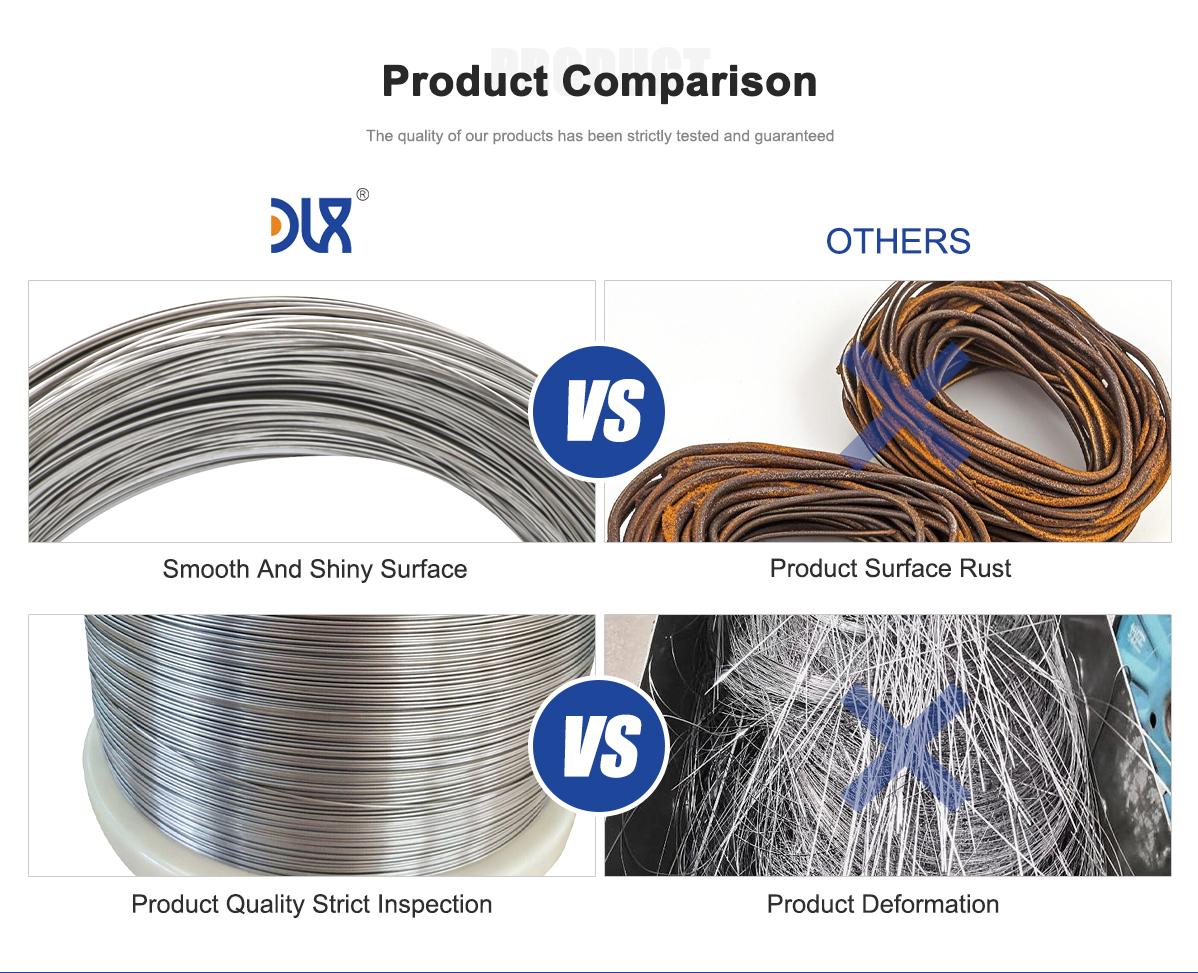

When you stack our Custom Diameter Nimonic 90 Spring Wire against typical market offerings, our company’s advantages are clear. We go beyond standard specs by focusing on precision and customization. Our wire boasts 20-35% longer fatigue life in high-heat cycles, thanks to defect-free drawing and tailored heat treatments that enhance creep resistance. While some alternatives might offer limited diameter ranges, our 0.05-12mm flexibility means you get exactly what your project needs, minimizing material waste and machining costs. We also invest heavily in R&D, testing our wire in simulated extreme heat environments to ensure it exceeds expectations—think rupture strengths of 120 MPa after 1000 hours at 920°C. Sustainability is another edge; our recycling initiatives and efficient production lower environmental impact without compromising quality, aligning with 2025’s green trends. This translates to real benefits: fewer replacements, less downtime, and better ROI in industries where reliability is everything. Our technical support team is on hand to guide you from design to deployment, ensuring seamless integration. Choosing us means getting a partner committed to delivering high-temperature spring wire that outperforms in the toughest conditions.

Digging deeper into the product, the ability to customize diameters is a standout feature. Standard wires often force engineers to compromise, but our process allows precise sizing to match load requirements, whether for delicate aerospace actuators or heavy industrial springs. The nickel-heavy composition ensures low thermal expansion, critical for maintaining tight tolerances in extreme heat. Our optional oxidation-resistant coatings add an extra layer of protection, reducing scale formation in high-temperature environments like furnaces or turbines.

Industry trends in 2025 highlight a shift toward smarter alloys. Aerospace is driving demand for materials that support hypersonic flight, where temperatures soar beyond traditional limits. Renewable energy systems, like next-gen geothermal plants, are adopting Nimonic 90 for its ability to handle heat and stress in compact designs. Additive manufacturing is transforming production, with laser-based methods enabling intricate spring wire applications that were once impossible. Recycling efforts are also key, with up to 20% of nickel alloys now sourced from scrap, easing supply chain pressures.

Comparison Parameters Table

| Parameter | Standard Nimonic 90 Spring Wire | Our Custom Diameter Nimonic 90 Spring Wire for Extreme Heat Applications | Notes |

|---|---|---|---|

| Composition | Ni 54-62%, Cr 18-21%, Co 15-21%, Ti 2-3%, Al 1-2% | Optimized with precise trace elements for uniformity | Ensures consistent performance across custom specs |

| Tensile Strength (Room Temp) | 1200-1400 MPa | 1300-1500 MPa | Enhanced by tailored heat treatment |

| Creep Resistance (at 920°C) | ~100 MPa after 1000 hours | ~120 MPa after 1000 hours | Superior for prolonged heat exposure |

| Oxidation Resistance | Good up to 950°C | Excellent up to 950°C with optional coatings | Reduces scaling in extreme heat |

| Fatigue Life | Standard under thermal cycling | 20-35% longer in high-heat cycles | Precision drawing minimizes defects |

| Diameter Range | 0.1-5 mm | 0.05-12 mm fully customizable | Meets diverse design requirements |

| Temperature Capability | Up to 920°C | Optimized for sustained 920°C+ performance | Ideal for extreme heat applications |

| Cost Efficiency | Market standard | Higher value via tailored sizing and durability | Reduces waste and replacement frequency |

Applications extend to emerging fields like hydrogen production, where our wire supports high-temperature valves in electrolysis systems. In automotive, hybrid vehicle turbo systems use it for springs that endure heat spikes without losing tension. Industrial furnaces rely on it for conveyor springs, resisting deformation in continuous 900°C+ operations.

Our company’s strengths lie in our obsessive attention to detail. We use advanced spectrometry to ensure alloy purity, minimizing inclusions that could weaken performance. Our supply chain is optimized for quick delivery, even amid market volatility, and our certifications meet stringent aerospace and energy standards. By focusing on custom solutions and sustainable practices, we deliver Nimonic 90 spring wire that not only meets but redefines industry expectations for extreme heat applications.

In short, our Custom Diameter Nimonic 90 Spring Wire for Extreme Heat Applications is built to excel where heat is relentless. It’s a product that embodies precision, durability, and innovation, ready to power the next generation of high-temperature engineering solutions.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the material makeup of Nimonic 90 alloy?

Nimonic 90 is a nickel-based superalloy with 54-62% nickel, 18-21% chromium, 15-21% cobalt, 2-3% titanium, 1-2% aluminum, and trace elements for enhanced strength.

What are the key features of Nimonic 90 spring wire for extreme heat?

It offers superior creep resistance up to 920°C, high tensile strength, excellent oxidation resistance, and customizable diameters for precise performance in extreme heat.

What are the main applications for custom diameter Nimonic 90 spring wire?

It's used in gas turbine springs, aerospace engine components, high-temperature fasteners, and industrial furnace parts requiring reliability under intense heat.

How does Nimonic 90 spring wire perform in extreme heat environments?

The alloy maintains structural stability and elasticity under prolonged high temperatures up to 920°C, resisting creep and thermal fatigue effectively.

Which industries rely on custom diameter Nimonic 90 spring wire?

Aerospace, power generation, petrochemical, and high-performance automotive sectors use it for components in extreme heat conditions.

What are the 2025 industry trends for superalloys like Nimonic 90?

Trends include growth in additive manufacturing, sustainable alloy recycling, increased demand in renewable energy systems, and enhanced heat resistance for next-gen turbines.

Why is custom diameter important for Nimonic 90 spring wire in extreme heat applications?

Custom diameters ensure precise fit and force in specialized designs, optimizing performance and reducing material waste in high-temperature systems.

How is custom diameter Nimonic 90 spring wire manufactured?

Through vacuum melting, precision hot rolling, cold drawing to tailored diameters, and age-hardening to maximize creep resistance and mechanical properties.