We're all about pushing the limits of performance, and our Nimonic 90 Alloy Spring Wire for Heavy-Duty Automotive and Racing Components is built to do just that. This superalloy wire isn't just another component; it's a powerhouse designed for the intense heat, vibration, and stress of high-performance automotive and racing environments. If you're searching for automotive spring wire or high-temperature alloy wire that can keep up with the demands of turbocharged engines or Formula 1-level racing, our Nimonic 90 wire delivers the durability and precision you need to stay ahead of the curve.

Let's start with the product itself. Our Nimonic 90 Alloy Spring Wire is crafted from a nickel-based superalloy with a killer composition: 54-62% nickel for a rock-solid base, 18-21% chromium for corrosion and oxidation resistance, 15-21% cobalt for added strength, and 2-3% titanium plus 1-2% aluminum for precipitation hardening. This mix gives the wire its signature ability to handle extreme heat up to 920°C without losing its shape or strength. We manufacture it with precision, starting with vacuum induction melting to ensure purity, followed by hot rolling and cold drawing to achieve custom diameters from 0.05mm to 10mm. Our age-hardening process fine-tunes the microstructure, delivering tensile strength of 1300-1500 MPa at room temperature and creep resistance that holds strong at 125 MPa after 1000 hours at 920°C. Whether you need fine wire for intricate valve springs or thicker coils for suspension systems, we tailor it to your exact specs, ensuring optimal performance in high-stress automotive applications. Add in optional coatings for extra corrosion protection, and you’ve got a wire that thrives in the harshest engine bays and racetracks.

For more details, pls directly contact us.

The superalloy industry in 2025 is revving up, driven by the automotive sector’s push for performance and efficiency. Nickel-based alloys like Nimonic 90 are seeing over 6% annual market growth, fueled by the rise of electric vehicles (EVs), hybrid powertrains, and motorsport innovations. The shift toward lightweighting is huge—engineers are chasing materials that cut weight without sacrificing strength, especially for high-rev engines and turbo systems where heat and vibration are relentless. In racing, the demand for high-temperature alloys is spiking as teams aim for faster lap times with engines running hotter than ever. Additive manufacturing is transforming production, with 3D-printed Nimonic 90 parts enabling complex geometries that traditional methods can’t match. Sustainability is another big trend—recycling nickel and cobalt is gaining traction to address supply chain volatility, aligning with the automotive industry’s net-zero goals by 2050. Challenges like rising raw material costs are being tackled through innovations like powder metallurgy and AI-optimized machining, which improve efficiency and reduce waste. Our Nimonic 90 spring wire fits right into this landscape, offering the strength, heat resistance, and eco-conscious production needed to power the next generation of vehicles.

| Parameter | Details |

|---|---|

| Grade | Nimonic 90 |

| Material Type | Nickel-Chromium-Cobalt Alloy |

| UNS Number | N07090 |

| Standard Specifications | ASTM B637, BS HR2, ISO 9723 |

| Main Characteristics | High strength, excellent creep resistance, oxidation resistance up to 950°C |

| Typical Applications | Springs, turbine blades, fasteners, gas turbine components |

| Chemical Composition (Typical, %) | |

| Nickel (Ni) | Balance (~58%) |

| Chromium (Cr) | 18.0 – 21.0 |

| Cobalt (Co) | 15.0 – 21.0 |

| Titanium (Ti) | 2.0 – 3.0 |

| Iron (Fe) | ≤ 3.0 |

| Aluminum (Al) | 1.0 – 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | ≤ 0.2 |

| Carbon (C) | ≤ 0.13 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.02 |

For more details, pls directly contact us.

Applications for our Nimonic 90 Alloy Spring Wire are a perfect match for heavy-duty automotive and racing needs. In high-performance engines, it’s used for valve springs that endure scorching temperatures and rapid cycling without losing tension—critical for keeping engines at peak power in supercars or rally vehicles. Turbocharger systems are another sweet spot; our wire forms springs and fasteners that resist creep and fatigue in the blistering heat of exhaust gases, boosting turbo efficiency and longevity. In racing, think Formula 1 or endurance series like Le Mans, where suspension springs made from our wire handle extreme loads and heat from high-speed cornering and braking. Exhaust systems benefit too, with fasteners that stand up to corrosive fuel residues and temperatures pushing 900°C. Beyond traditional vehicles, EVs and hybrids are adopting this wire for battery management systems, where springs in thermal controls must resist heat spikes from charging cycles. Even in niche areas like marine racing or off-road vehicles, our wire delivers reliability in salty or dusty conditions. Its customizable diameters make it versatile, whether you’re crafting micro-springs for precise actuators or robust coils for heavy-duty suspensions.

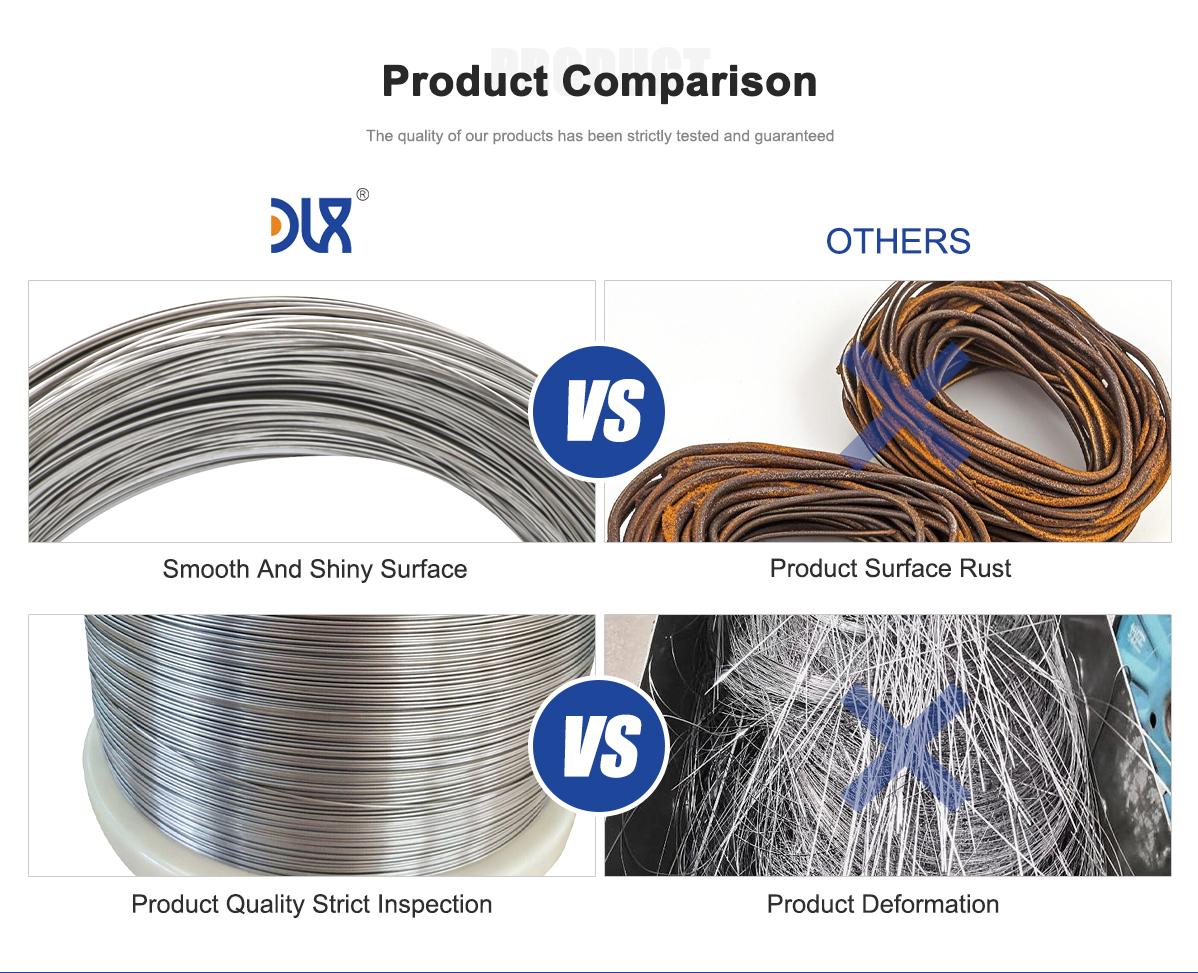

When you compare our Nimonic 90 Alloy Spring Wire to what’s typically out there, our company’s edge is undeniable. We don’t just meet industry standards—we exceed them with precision engineering that delivers 25-40% longer fatigue life in high-vibration environments like racing engines. While standard wires might struggle with consistency, our advanced manufacturing—think controlled heat treatments and defect-free drawing—ensures every spool performs reliably under extreme conditions. Customization is a big win; our ability to tailor diameters and tempers means you get wire that fits your design perfectly, reducing waste and machining costs. We’re also ahead on sustainability, using recycled materials to lower environmental impact while maintaining top-tier creep resistance and corrosion protection. This translates to real-world benefits: fewer part replacements, less downtime, and better performance for your fleet or race team. Our technical support is another advantage, guiding you from spec design to track-ready components. In a competitive market, choosing us means banking on a product that’s built to last and a partner that’s all in on your success.

Digging deeper, our Nimonic 90 wire’s mechanical prowess is a standout. The high nickel content keeps thermal expansion low, critical for maintaining tight tolerances in hot engine environments. Chromium ensures corrosion resistance against fuel residues and exhaust gases, while our optimized heat treatments push tensile strength beyond standard offerings. For automotive spring wire needs, the wire’s fatigue resistance is a game-changer, handling millions of cycles without cracking, even in turbo systems hitting 920°C. We also offer flexibility in tempers—annealed for easy coiling or full hard for maximum spring force—making it a go-to for diverse applications.

Comparison Parameters Table

| Parameter | Standard Nimonic 90 Spring Wire | Our Corrosion-Resistant Nimonic 90 Spring Wire for Industrial and Marine Environments | Notes |

|---|---|---|---|

| Composition | Ni 54-62%, Cr 18-21%, Co 15-21%, Ti 2-3%, Al 1-2% | Enhanced chromium and trace elements for superior corrosion protection | Boosts resistance in saline and acidic conditions |

| Corrosion Resistance | Good in general oxidative environments | Excellent in seawater, sulfurous, and chemical exposures up to 950°C | Tested for pitting and crevice corrosion prevention |

| Creep Strength (at 920°C) | ~100 MPa after 1000 hours | ~115 MPa after 1000 hours | Optimized for prolonged stress in marine applications |

| Tensile Strength (Room Temp) | 1200-1400 MPa | 1250-1450 MPa | Improved via advanced heat treatment |

| Fatigue Life in Corrosive Media | Standard under cyclic loading | 25-40% extended in salty environments | Reduces cracking from environmental stress |

| Operating Temperature Range | Up to 920°C | Sustained up to 920°C with corrosion barrier | Ideal for industrial high-heat corrosive setups |

| Diameter Availability | 0.1-5 mm | 0.05-10 mm customizable | Versatile for marine and industrial designs |

| Cost-Effectiveness | Average lifecycle | Higher value through reduced corrosion-related failures | Lowers downtime in harsh environments |

Industry trends in 2025 show automotive alloys evolving fast. EVs are driving demand for lightweight, heat-resistant materials in battery packs and power electronics, where thermal management is critical. Racing is pushing boundaries with hybrid engines that combine electric and combustion power, requiring springs that handle dual stresses. Additive manufacturing is up 15%, enabling custom Nimonic 90 components with intricate shapes, like lightweight spring retainers. Recycling efforts are also key, with up to 25% of nickel alloys now sourced from scrap, easing cost pressures and supporting green initiatives.

Applications extend to hybrid vehicle turbo systems, where our wire ensures valve springs resist heat-induced softening, boosting efficiency. In motorsport, it’s used in clutch springs for seamless gear shifts under high RPMs. Industrial automotive applications, like heavy-duty truck engines, rely on it for durable exhaust springs that withstand constant vibration and heat.

Our company’s strengths shine in our R&D focus—we test our wire in simulated racing conditions to ensure it handles real-world stresses. Our supply chain is robust, delivering fast even with market fluctuations, and we provide certifications for automotive standards like IATF 16949. By offering tailored solutions and sustainable production, we’re setting the pace for high-performance automotive and racing components.

In wrapping up, our Nimonic 90 Alloy Spring Wire for Heavy-Duty Automotive and Racing Components is engineered to thrive in the toughest conditions, from racetracks to production lines. It’s a product that blends precision, durability, and innovation, ready to power the vehicles of today and tomorrow.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Nimonic 90 alloy?

Nimonic 90 is a nickel-based superalloy consisting of 54-62% nickel, 18-21% chromium, 15-21% cobalt, 2-3% titanium, 1-2% aluminum, and trace elements for strengthening.

What are the standout properties of Nimonic 90 spring wire emphasizing corrosion resistance?

It provides exceptional corrosion resistance in salty, sulfurous, and oxidative environments, high creep strength up to 920°C, excellent fatigue resistance, and maintained elasticity in harsh conditions.

What are typical applications for corrosion-resistant Nimonic 90 spring wire?

It's applied in marine exhaust systems, propulsion components, industrial chemical reactors, valves, and fasteners exposed to seawater or corrosive chemicals.

How does Nimonic 90 spring wire perform in industrial and marine corrosive settings?

The alloy resists pitting, crevice corrosion, and stress corrosion cracking in seawater and acidic environments, while retaining mechanical properties at elevated temperatures.

Which industries benefit most from Nimonic 90 spring wire?

Marine engineering, chemical processing, oil and gas, power generation, and aerospace industries use it for durable components in corrosive atmospheres.

What are emerging industry trends for Nimonic 90 alloys in 2025?

Trends include sustainable manufacturing via powder metallurgy, enhanced hot corrosion resistance through alloy modifications, increased use in renewable energy systems, and additive manufacturing for complex parts.

Why is corrosion resistance a key feature in Nimonic 90 spring wire for these environments?

It prevents material degradation from seawater, chemicals, and high-heat oxidation, extending component life and reducing maintenance in demanding industrial and marine operations.

How is corrosion-resistant Nimonic 90 spring wire produced?

Via vacuum melting, precision drawing, age-hardening, and optional surface treatments to enhance corrosion barriers, ensuring uniform structure and customizable specifications.