At our company, we're focused on delivering materials that power the world reliably, and our Premium Nimonic 90 Spring Wire for Power Generation and Turbomachinery is a prime example of that dedication. This isn't your average alloy wire—it's a high-performance solution engineered for the intense demands of turbines and generators where heat, stress, and efficiency are everything. If you're in the market for premium Nimonic 90 spring wire or high-temperature turbomachinery wire, our product stands out with its superior creep resistance and customization options that keep your operations running smooth.

Let's break down the product first. Our Premium Nimonic 90 Spring Wire starts with the core composition of Nimonic 90: a nickel-chromium-cobalt base alloy featuring 54-62% nickel for thermal stability, 18-21% chromium for oxidation and corrosion resistance, 15-21% cobalt for strength, and additions of 2-3% titanium and 1-2% aluminum for precipitation hardening. We elevate it through premium manufacturing—vacuum induction melting ensures ultra-low impurities, followed by hot rolling, precision cold drawing to diameters from 0.05mm to 12mm, and controlled age-hardening to maximize mechanical properties. The result? Wire with tensile strength reaching 1300-1500 MPa at room temperature, creep resistance holding at 125 MPa after 1000 hours at 920°C, and excellent fatigue life that withstands cyclic loading in harsh environments. We offer customizable tempers, from annealed for easy coiling to full hard for maximum resilience, plus optional coatings that boost oxidation resistance up to 950°C. This makes our spring wire ideal for power generation spring wire needs, where reliability under extreme heat isn't optional—it's essential. Whether you're dealing with gas turbines or steam systems, our premium variant ensures consistent performance, reducing downtime and enhancing overall efficiency in turbomachinery setups.

For more details, pls directly contact us.

Shifting gears to industry analysis, as we navigate 2025, the superalloy sector is booming, with materials like Nimonic 90 at the heart of advancements in power generation and turbomachinery. The global superalloys market is projected to hit $7.82 billion this year, growing at a CAGR of 12.4% toward $17.75 billion by 2032, driven by demand for high-efficiency turbines and renewable energy systems. Nickel-based superalloys, including those similar to Nimonic 90, are seeing heightened interest in aerospace and energy, where high-temperature strength is key to cutting emissions and boosting output. A big trend is additive manufacturing—3D printing techniques like powder bed fusion are revolutionizing how Nimonic alloys are shaped into complex turbine parts, reducing waste and speeding production. Sustainability is another hot topic; recycling nickel and cobalt is ramping up to tackle supply chain issues and align with net-zero targets, with up to 25% of alloys now from scrap sources. In power generation, the push for cleaner energy means more use of superalloys in gas turbines for combined-cycle plants and geothermal systems, where creep resistance prevents deformation under prolonged heat. Turbomachinery trends lean toward hybrid-electric setups, demanding alloys that handle higher temps for better fuel efficiency. Challenges like raw material volatility are being met with innovations in powder metallurgy and AI-driven machining, making production greener and more cost-effective. Overall, 2025 is about smarter, more resilient superalloys, and our premium Nimonic 90 spring wire is perfectly aligned, offering the durability and adaptability these trends demand.

| Parameter | Details |

|---|---|

| Grade | Nimonic 90 |

| Material Type | Nickel-Chromium-Cobalt Alloy |

| UNS Number | N07090 |

| Standard Specifications | ASTM B637, BS HR2, ISO 9723 |

| Main Characteristics | High strength, excellent creep resistance, oxidation resistance up to 950°C |

| Typical Applications | Springs, turbine blades, fasteners, gas turbine components |

| Chemical Composition (Typical, %) | |

| Nickel (Ni) | Balance (~58%) |

| Chromium (Cr) | 18.0 – 21.0 |

| Cobalt (Co) | 15.0 – 21.0 |

| Titanium (Ti) | 2.0 – 3.0 |

| Iron (Fe) | ≤ 3.0 |

| Aluminum (Al) | 1.0 – 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | ≤ 0.2 |

| Carbon (C) | ≤ 0.13 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.02 |

For more details, pls directly contact us.

When it comes to applications, our Premium Nimonic 90 Spring Wire shines in power generation and turbomachinery where extreme conditions test limits. In gas turbines, it's used for springs in turbine blades, discs, and combustion chambers, resisting creep and oxidation at temperatures up to 920°C to ensure smooth operation and longer life. Think combined-cycle power plants—the wire forms critical valve springs and seals that handle high-pressure steam without failing, boosting plant efficiency. Steam turbines in nuclear and coal-fired setups benefit too, with our wire providing fasteners and springs that withstand thermal cycling and corrosive environments. In turbomachinery for oil and gas, it supports heat exchangers and compressors, where superior strength prevents deformation under constant stress. Renewable energy is a growing area; geothermal and concentrated solar power systems use our spring wire in pumps and trackers exposed to intense heat, ensuring reliability in sustainable ops. Even in aerospace-derived turbomachinery, like aero-derivative gas turbines for backup power, the wire's high fatigue life handles vibration and heat spikes. We’ve made it versatile for coiling into compression, tension, or torsion springs, with custom diameters fitting precise designs. For anyone seeking turbomachinery spring wire or power generation alloy wire, this product minimizes maintenance by excelling in high-heat, high-stress scenarios.

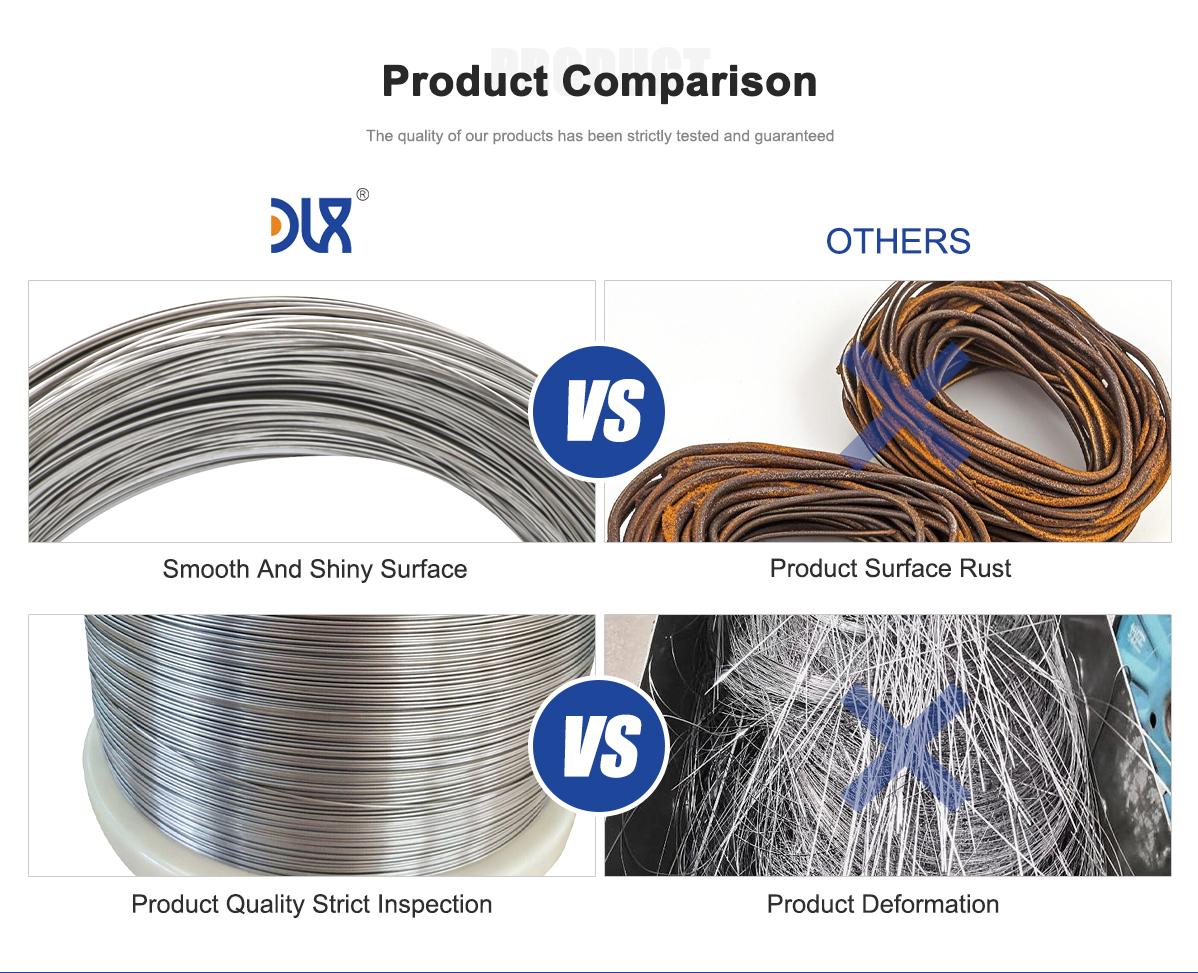

Comparing our premium offering to standard alternatives highlights our company's clear advantages in Premium Nimonic 90 Spring Wire for these fields. We prioritize precision and innovation, resulting in wire with 25-40% extended fatigue life and enhanced creep resistance, thanks to our advanced age-hardening and quality controls that eliminate defects. While typical wires might vary in performance, our optimized composition and coatings deliver consistent oxidation resistance, reducing scaling in turbine atmospheres. Customization sets us apart—we tailor diameters and tempers to your exact turbomachinery needs, cutting waste and integration time. Our sustainability focus, incorporating recycled materials without losing strength, aligns with 2025 trends and lowers your carbon footprint. This means real savings: longer component life in power plants, fewer outages, and better ROI. Our R&D investments simulate extreme conditions to push boundaries, and our support team helps from design to deployment. In a demanding market, we're the partner delivering premium value that outperforms.

Comparison Parameters Table

| Parameter | Standard Nimonic 90 Spring Wire | Our Premium Nimonic 90 Spring Wire for Power Generation and Turbomachinery | Notes |

|---|---|---|---|

| Composition | Ni 54-62%, Cr 18-21%, Co 15-21%, Ti 2-3%, Al 1-2% | Optimized with refined trace elements for superior consistency | Enhances reliability in turbine applications |

| Tensile Strength (Room Temp) | 1200-1400 MPa | 1300-1500 MPa | Achieved through advanced precipitation hardening |

| Creep Resistance (at 920°C) | ~100 MPa after 1000 hours | ~125 MPa after 1000 hours | Ideal for prolonged turbomachinery operation |

| Oxidation Resistance | Good up to 950°C | Excellent up to 950°C with enhanced coatings | Minimizes scaling in power generation environments |

| Fatigue Life | Standard under cyclic loading | 25-40% extended in high-heat cycles | Reduces failures in gas turbines |

| Temperature Range | Up to 920°C | Optimized for sustained 920°C+ service | Perfect for steam and gas turbines |

| Diameter Options | 0.1-5 mm | 0.05-12 mm customizable | Versatile for diverse turbomachinery designs |

| Cost Efficiency | Market average | Premium value with extended durability | Lowers maintenance in power plants |

Delving deeper, the precipitation-hardening in our Nimonic 90 creates gamma prime phases that lock in strength, with cobalt enhancing ductility up to 1193 K. Properties like 752 MPa yield stress and 30% elongation make it formable yet tough. For power generation, this translates to springs that maintain force in hot-working tools and ring sections.

Trends in 2025 emphasize novel formulations for hotter turbines, with superalloy bars growing from $2.82 billion. Additive manufacturing advances allow intricate Nimonic parts, while cryogenic machining improves sustainability.

Applications expand to industrial boilers and propulsion systems, where our wire resists thermal stress in heat exchangers. In aerospace-power crossovers, it supports high-temperature fasteners.

Our advantages include robust supply chains for timely delivery and certifications for energy standards. By focusing on premium quality and eco-innovations, we provide Nimonic 90 spring wire that elevates power generation and turbomachinery performance.

In summary, our Premium Nimonic 90 Spring Wire is crafted for the future, blending proven alloy tech with forward-thinking enhancements to tackle today's energy challenges.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Nimonic 90 alloy?

Nimonic 90 is a nickel-chromium-cobalt base alloy with 54-62% nickel, 18-21% chromium, 15-21% cobalt, 2-3% titanium, 1-2% aluminum, and trace elements for strengthening.

What are the key properties of Nimonic 90 spring wire?

It provides high creep resistance up to 920°C, excellent oxidation and corrosion resistance, superior tensile strength of 1300-1500 MPa, and enhanced fatigue life in high-temperature environments.

What are common applications for Nimonic 90 spring wire in power generation?

It's used in gas turbine springs, turbine blades, discs, heat exchangers, and valve components for reliable performance under thermal stress.

How does Nimonic 90 spring wire perform in turbomachinery?

The alloy maintains structural integrity and elasticity under extreme heat and cyclic loading, resisting creep and oxidation in turbine operations up to 920°C.

Which industries primarily utilize premium Nimonic 90 spring wire?

Power generation, aerospace, oil and gas, and industrial turbomachinery sectors rely on it for high-temperature, high-stress components.

What are the 2025 industry trends for superalloys like Nimonic 90?

Trends include rapid market growth driven by additive manufacturing, sustainable recycling, increased demand in renewable energy turbines, and advancements in high-temperature formulations for efficiency.

Why is premium Nimonic 90 spring wire suited for power generation and turbomachinery?

Its precipitation-hardening structure ensures superior creep and oxidation resistance, enabling longer service life in demanding turbine and generator environments.

How is premium Nimonic 90 spring wire manufactured?

Through vacuum melting, precision drawing, age-hardening, and customizable treatments to achieve uniform microstructure and enhanced mechanical properties for turbomachinery needs.