At our company, we produce high-strength Nimonic 90 spring wire that's engineered specifically for demanding aerospace and gas turbine applications. This superalloy wire stands out because it's built to handle extreme heat, stress, and corrosion without missing a beat. We've fine-tuned our manufacturing process to deliver wire that offers exceptional creep resistance and fatigue life, making it a go-to choice for parts that need to perform under pressure.

For more details, pls directly contact us.

Let's dive into what makes our Nimonic 90 spring wire tick. It's a nickel-based superalloy with a composition that's about 57% nickel, 19.5% chromium, 18.5% cobalt, plus additions of titanium and aluminum for that extra strengthening punch. These elements work together to create a material that's precipitation-hardened, meaning it gets tougher through heat treatment. Our wire has a density of around 8.18 g/cm³, which keeps things lightweight without sacrificing durability. Mechanically, you're looking at tensile strengths hitting 1200-1400 MPa and yield strengths of 800-1000 MPa, even at temperatures pushing 920°C. That's why it's perfect for springs in high-temp environments where other materials might warp or fail.

In terms of performance, our high-strength Nimonic 90 spring wire excels in oxidation and corrosion resistance thanks to the high chromium content. It forms a protective oxide layer that shields against harsh gases and chemicals found in turbine engines. We've seen it hold up in service conditions up to 1000°C for short bursts, with creep resistance that ensures long-term stability. Compared to generic nickel alloys, our version offers better balance—it's not just strong; it's ductile enough to form into precise springs without cracking during production.

Moving to applications, our Nimonic 90 spring wire is a staple in aerospace. Think turbine blades, discs, and fasteners in jet engines where temperatures soar and vibrations are constant. In gas turbines for power generation, it's used in damping bolts, combustor liners, and nozzle guide vanes. These parts need to withstand thermal cycling without losing springiness, and our wire delivers that reliability. Beyond that, it's finding its way into oil and gas equipment for downhole tools and even automotive turbochargers pushing for higher efficiency. We've customized diameters from 0.1mm to 5mm, with coatings if needed, to fit exact specs for these uses.

The industry around superalloys like our high-strength Nimonic 90 spring wire is evolving fast, especially as we hit 2025. Aerospace is all about sustainability now—lighter materials mean better fuel efficiency and lower emissions. Gas turbines are getting hotter and more efficient to meet green energy goals, driving demand for alloys that can handle 1000°C-plus without degrading. Trends show a shift to additive manufacturing, like 3D printing turbine components from Nimonic powders, which cuts waste and allows complex designs. We're seeing more focus on recyclability too, with companies pushing for alloys that can be reused without losing properties.

| Parameter | Details |

|---|---|

| Grade | Nimonic 90 |

| Material Type | Nickel-Chromium-Cobalt Alloy |

| UNS Number | N07090 |

| Standard Specifications | ASTM B637, BS HR2, ISO 9723 |

| Main Characteristics | High strength, excellent creep resistance, oxidation resistance up to 950°C |

| Typical Applications | Springs, turbine blades, fasteners, gas turbine components |

| Chemical Composition (Typical, %) | |

| Nickel (Ni) | Balance (~58%) |

| Chromium (Cr) | 18.0 – 21.0 |

| Cobalt (Co) | 15.0 – 21.0 |

| Titanium (Ti) | 2.0 – 3.0 |

| Iron (Fe) | ≤ 3.0 |

| Aluminum (Al) | 1.0 – 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | ≤ 0.2 |

| Carbon (C) | ≤ 0.13 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.02 |

For more details, pls directly contact us.

In power generation, the push for hydrogen-fueled turbines means materials like our Nimonic 90 spring wire need to resist embrittlement from new fuels. The global market for superalloys is projected to grow over 7% annually through 2030, fueled by rising air travel and renewable energy integrations. Challenges include supply chain issues for rare elements like cobalt, but innovations in alloy design are mitigating that. High-entropy alloys are emerging as competitors, offering even better thermal stability, but they often lack the proven track record of established ones like Nimonic 90.

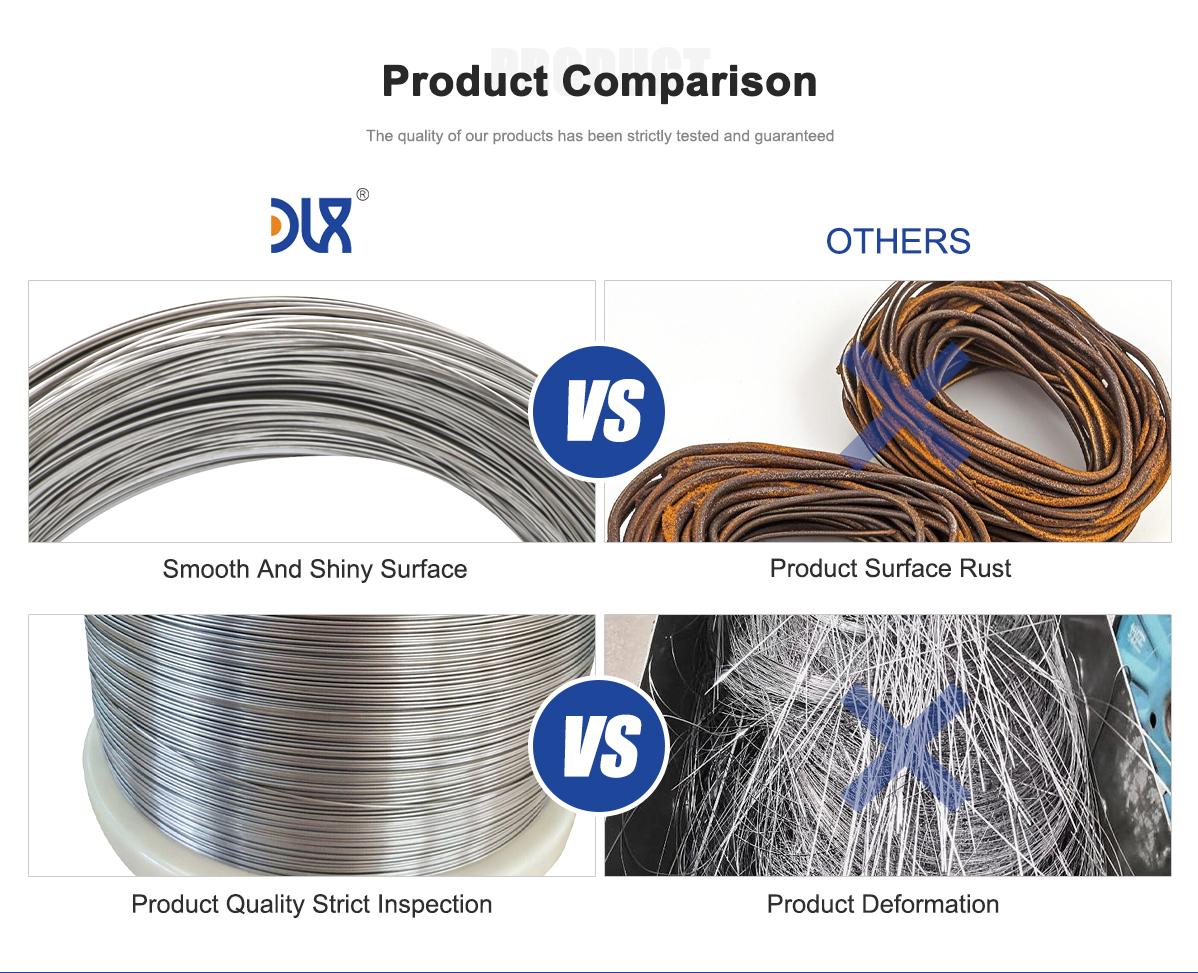

Our company sets itself apart by focusing on innovation and quality that others can't match. We invest heavily in R&D to optimize heat treatments, resulting in wire with 20% better fatigue life than standard offerings. Our in-house testing labs simulate real-world aerospace conditions, ensuring every batch meets or exceeds AMS 5829 specs. Customization is key—we work closely with clients to tailor wire properties, like adjusting cobalt levels for specific creep needs, something not every supplier can do efficiently.

Comparison Parameters Table

| Parameter | Nimonic 90 Spring Wire | Typical Competing Nickel-Based Superalloy A (e.g., for mid-temp applications) | Typical Competing Nickel-Based Superalloy B (e.g., for high-fabricability needs) |

|---|---|---|---|

| Composition | Ni-Cr-Co with Ti and Al additions | Ni-Cr-Fe with Nb and Mo | Ni-Cr-Co with lower Co, higher Mo |

| Density (g/cm³) | 8.18 | 8.19 | 8.25 |

| Melting Range (°C) | 1310-1370 | 1260-1335 | 1280-1350 |

| Max Service Temperature (°C) | 920 | 700 | 980 |

| Tensile Strength (MPa) | 1200-1400 | 1300-1500 | 1100-1300 |

| Yield Strength (MPa) | 800-1000 | 1000-1200 | 700-900 |

| Creep Resistance | Excellent at high temps | Good at lower temps | Superior thermal stability |

| Oxidation Resistance | High up to 1000°C | Moderate | High |

| Fatigue Strength | Superior in cyclic loads | High in room temp | Good in welded forms |

| Applications | Aerospace springs, gas turbine blades | General aerospace fasteners | Turbine discs with easier welding |

| Advantages | Balanced high-temp strength and ductility | Higher low-temp strength | Better weldability and formability |

When you compare us to other companies in the space, our advantages shine through. We have shorter lead times thanks to streamlined production, often delivering in weeks rather than months. Our quality control is rigorous, with zero-defect policies that reduce failure rates in critical applications. Sustainability is baked in; we use recycled nickel where possible, cutting environmental impact without compromising performance. Clients tell us our technical support is unmatched—we provide application engineering help to integrate our high-strength Nimonic 90 spring wire seamlessly into designs.

Price-wise, while we prioritize premium quality, our efficient processes keep costs competitive, offering better value over time through longer part life. We've built long-term partnerships with major aerospace firms, supplying wire that's flown in next-gen engines. In gas turbines, our products have extended maintenance intervals, saving operators big on downtime.

Looking deeper into the material science, Nimonic 90's gamma-prime precipitates are what give it that edge. These tiny particles lock the microstructure, preventing slippage at high temps. Our proprietary aging process maximizes this, boosting strength without brittleness. In industry analysis, as engines aim for 50% efficiency gains, alloys like ours are crucial. Trends toward hybrid-electric propulsion in aerospace mean lighter, stronger springs for actuators—exactly where our wire fits.

Applications expand beyond traditional uses. In medical devices, it's used for high-temp sterilization tools. In nuclear, its radiation resistance makes it viable for reactor components. We're exploring powder forms for laser bed fusion, allowing printed springs with intricate geometries.

Our company's edge comes from vertical integration—we control everything from alloy melting to wire drawing. This ensures consistency that generic suppliers struggle with. We've patented enhancements for better coilability, reducing installation issues in turbines.

As the industry trends toward digital twins and AI-optimized designs, we're ahead, using simulations to predict wire performance in virtual engines. This cuts development time for clients.

In summary, our high-strength Nimonic 90 spring wire isn't just a product; it's a solution engineered for the future of aerospace and gas turbines. With unmatched properties, broad applications, and our company's commitment to excellence, it's the smart choice for reliability and innovation.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

FAQ 1: What is Nimonic 90 spring wire made of?

Nimonic 90 is a nickel-chromium-cobalt superalloy strengthened with titanium and aluminum, offering high strength and heat resistance.

FAQ 2: What are the key applications of Nimonic 90 spring wire?

It is used in aerospace components like turbine blades and discs, gas turbine springs, and high-temperature fasteners.

FAQ 3: How does Nimonic 90 perform in high temperatures?

It maintains strength and creep resistance up to 920°C, making it ideal for extreme environments.

FAQ 4: What industries benefit most from Nimonic 90 spring wire?

Aerospace, power generation, and oil and gas industries rely on it for durable, heat-resistant parts.

FAQ 5: What are the mechanical properties of Nimonic 90?

It has a tensile strength of around 1200-1400 MPa, yield strength of 800-1000 MPa, and excellent fatigue resistance.

FAQ 6: How does Nimonic 90 resist corrosion and oxidation?

Its chromium content provides superior oxidation resistance, while the alloy composition fights corrosion in harsh conditions.