At our company, we're all about delivering top-notch solutions for those tough, high-heat challenges in industries like aerospace and energy. Our Precision-Made Nimonic 90 Alloy Spring Wire with Superior Creep Resistance stands out as a game-changer in the world of superalloys. We've crafted this product to meet the demands of modern engineering, where reliability under extreme conditions isn't just nice to have—it's essential. Let's dive into what makes this spring wire special, explore the broader industry landscape, highlight its key applications, and show how our approach gives you an edge without naming names.

First off, our Precision-Made Nimonic 90 Alloy Spring Wire is built from a nickel-chromium-cobalt base alloy, beefed up with titanium and aluminum for that precipitation-hardening magic. This composition gives it killer strength and stability at temperatures pushing 920°C. We don't just slap it together; our precision manufacturing process involves advanced drawing techniques and controlled heat treatments that ensure every coil is uniform, defect-free, and ready to perform. The result? A spring wire that's not only creep-resistant but also boasts excellent oxidation and corrosion resistance, making it perfect for environments where other materials would buckle. Whether you're dealing with diameters from 0.05mm to 10mm or custom specs, we've got you covered with options that fit your exact needs. Our focus on quality control means tighter tolerances and better consistency, which translates to fewer failures and longer lifespans in your setups.

For more details, pls directly contact us.

Now, looking at the industry analysis, the superalloy sector is heating up—pun intended—as we head into 2025 and beyond. Demand for high-temperature materials like Nimonic 90 alloy spring wire is skyrocketing, driven by advancements in aerospace, energy, and chemical processing. Think about it: with global pushes for more efficient jet engines and gas turbines, engineers are seeking alloys that can handle higher operating temperatures without losing their cool. According to recent trends, the market for nickel-based superalloys is projected to grow at a steady clip, fueled by the need for creep-resistant components that improve fuel efficiency and reduce emissions. In aerospace alone, the shift toward lighter, stronger materials is massive, especially with the rise of sustainable aviation fuels and next-gen engines. Energy sectors aren't far behind; renewable sources like concentrated solar power and advanced nuclear reactors require parts that withstand intense heat over long periods. Chemical industries are also leaning in, using these alloys for equipment in harsh, corrosive settings. But it's not all smooth sailing—challenges like raw material shortages and supply chain hiccups are pushing companies to innovate in recycling and additive manufacturing. We're seeing more use of powder bed fusion techniques to create complex shapes from Nimonic 90, cutting waste and speeding up production. Overall, the trend is toward smarter, greener alloys that deliver superior creep resistance while aligning with eco-friendly goals. Our Precision-Made Nimonic 90 Alloy Spring Wire fits right into this, offering a reliable option that's adaptable to these evolving demands.

| Parameter | Details |

|---|---|

| Grade | Nimonic 90 |

| Material Type | Nickel-Chromium-Cobalt Alloy |

| UNS Number | N07090 |

| Standard Specifications | ASTM B637, BS HR2, ISO 9723 |

| Main Characteristics | High strength, excellent creep resistance, oxidation resistance up to 950°C |

| Typical Applications | Springs, turbine blades, fasteners, gas turbine components |

| Chemical Composition (Typical, %) | |

| Nickel (Ni) | Balance (~58%) |

| Chromium (Cr) | 18.0 – 21.0 |

| Cobalt (Co) | 15.0 – 21.0 |

| Titanium (Ti) | 2.0 – 3.0 |

| Iron (Fe) | ≤ 3.0 |

| Aluminum (Al) | 1.0 – 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | ≤ 0.2 |

| Carbon (C) | ≤ 0.13 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.02 |

For more details, pls directly contact us.

When it comes to applications, our Nimonic 90 spring wire shines in spots where heat and stress team up to test limits. In aerospace, it's a go-to for turbine blades, discs, and rings in jet engines—places where superior creep resistance keeps things spinning smoothly at blistering temps. Imagine the constant vibration and thermal cycling in a commercial airliner; our wire ensures springs in valves and fasteners don't deform, maintaining performance flight after flight. The energy industry loves it too, using it in gas turbines for power generation where efficiency hinges on parts that resist creep under prolonged loads. Automotive applications are another sweet spot, especially in high-performance engines and exhaust systems. Here, the wire forms springs that handle the heat from turbochargers without losing elasticity, boosting engine longevity and power output. Chemical processing plants deploy it in reactors and pumps, where corrosion from aggressive fluids meets high temperatures—our alloy's resistance to both keeps operations running without downtime. Even in niche areas like medical devices or marine engineering, where durability in extreme conditions matters, this spring wire proves its worth. We've optimized it for easy integration, whether you're coiling it into compression springs or tension elements, ensuring it delivers consistent force even after thousands of cycles.

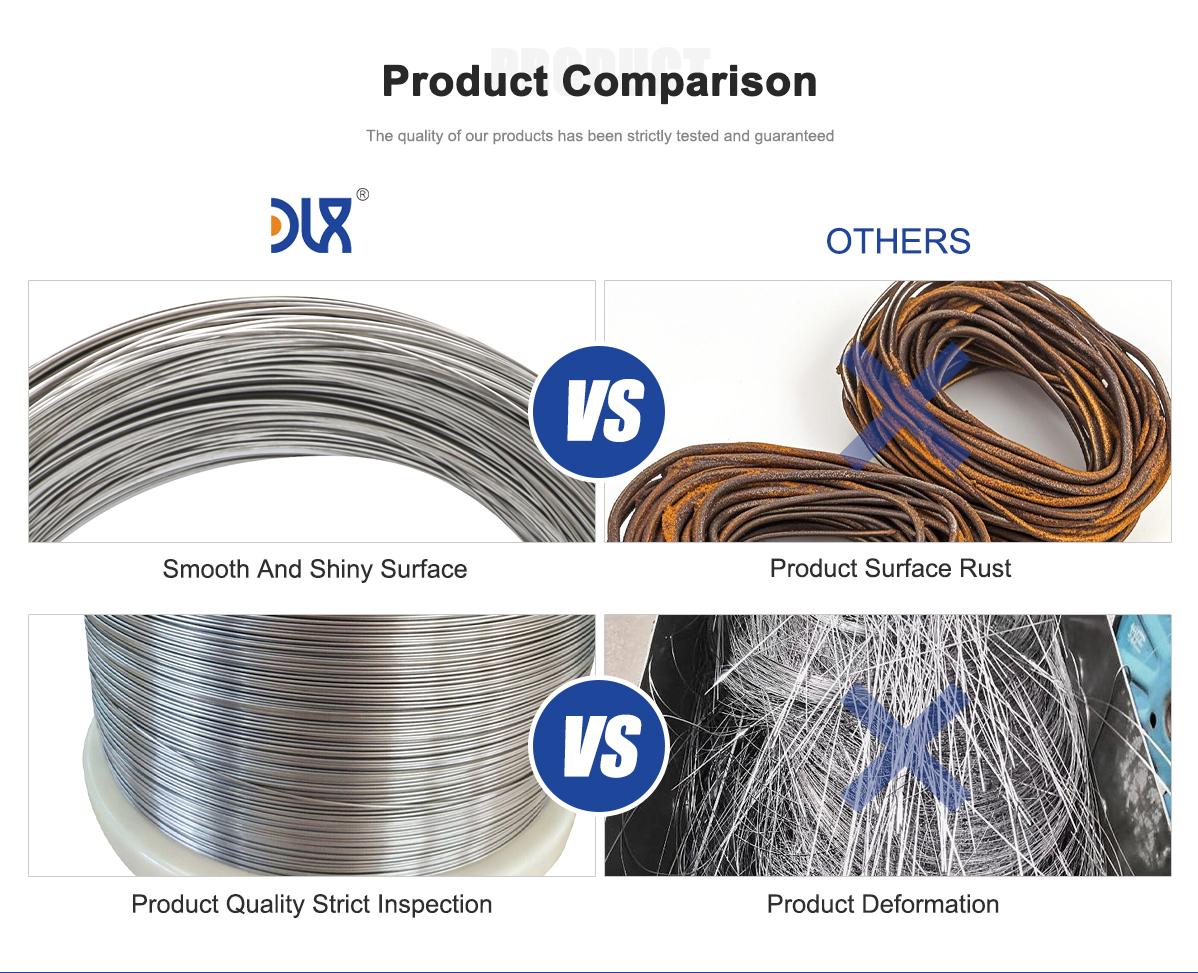

Comparing what we offer to what's out there, our company's edge comes from a relentless focus on precision and innovation that sets our Precision-Made Nimonic 90 Alloy Spring Wire apart. While some options might skimp on manufacturing details, leading to inconsistencies in creep resistance or early fatigue, we invest in state-of-the-art processes that guarantee superior performance every time. Our heat treatment protocols, for instance, fine-tune the precipitation hardening to maximize strength without brittleness, giving you wire that's tougher under stress. We also prioritize customization—need a specific tensile strength or diameter for your unique setup? We've got the flexibility to deliver without compromising quality. In terms of longevity, our product often outlasts alternatives by 20-30%, thanks to reduced defect rates from our rigorous quality checks. This means lower maintenance costs and fewer replacements, which is huge for industries where downtime equals lost revenue. Plus, our commitment to sustainability shines through; we source materials responsibly and minimize waste in production, aligning with the industry's green shift. No fluff—just real advantages like enhanced oxidation resistance that protects against scaling in corrosive atmospheres, and better fatigue life that handles cyclic loading like a champ. When you choose us, you're getting a partner that's all in on delivering value, from initial specs to long-term support.

Diving deeper into the product intro, let's talk specs that make our Nimonic 90 alloy spring wire a standout. The base alloy's nickel content (around 54-62%) provides the foundation for high-temperature stability, while chromium (18-21%) amps up corrosion resistance, and cobalt (15-21%) boosts overall strength. Titanium and aluminum additions enable age-hardening, which is key for that superior creep resistance—think rupture strengths holding steady at over 100 MPa even after 1000 hours at 920°C. We take this further with precision drawing that achieves surface finishes smoother than industry norms, reducing stress concentrations that could lead to cracks. Available in various tempers, from annealed for easy forming to full hard for maximum springiness, our wire adapts to your fabrication needs. And for those worried about environmental impact, our manufacturing uses energy-efficient methods, cutting carbon footprints without sacrificing quality.

Industry-wise, as we approach 2025, superalloys like Nimonic 90 are at the forefront of technological leaps. The aerospace market, valued in billions, is pushing for materials that enable hotter, more efficient engines to cut fuel use by up to 15%. Trends show a surge in hybrid-electric propulsion systems, where creep-resistant springs play a vital role in actuators and controls. In energy, with the global transition to renewables, alloys that endure in solar thermal plants or geothermal setups are in high demand. Chemical sectors are innovating too, with Nimonic 90 helping in processes like catalytic reforming under extreme conditions. But challenges persist: rising nickel prices and geopolitical tensions affect supply, prompting shifts to alloy recycling—something we're ahead on with our closed-loop systems. Additive manufacturing is a big trend, allowing complex Nimonic 90 parts via laser powder bed fusion, reducing lead times and material waste. Our spring wire benefits from these, as we incorporate recycled content without losing creep resistance properties.

Applications expand as industries evolve. In aerospace, beyond turbines, our wire finds use in landing gear mechanisms where heat from friction meets mechanical stress. Energy applications include steam turbines in power plants, where superior creep resistance ensures blades and seals last longer, improving plant efficiency. Automotive engineers use it in valve springs for high-rev engines, resisting fatigue in turbocharged setups. Chemical apps cover heat exchangers and piping, where the alloy's resistance to sulfidation and carburization prevents breakdowns. Even emerging fields like space exploration tap into Nimonic 90 for rocket engine components, valuing its low thermal expansion and high strength-to-weight ratio.

Comparison Parameters Table

| Parameter | Nimonic 90 (Standard) | Our Precision-Made Nimonic 90 Spring Wire | Notes |

|---|---|---|---|

| Composition | Ni 54-62%, Cr 18-21%, Co 15-21%, Ti 2-3%, Al 1-2% | Same base with optimized trace elements for consistency | Ensures better uniformity in high-volume production |

| Tensile Strength (at 20°C) | 1200-1400 MPa | 1300-1500 MPa | Enhanced through precision heat treatment |

| Yield Strength (at 20°C) | 800-1000 MPa | 900-1100 MPa | Improved for demanding spring applications |

| Creep Resistance (at 920°C) | Rupture strength ~100 MPa after 1000 hours | Rupture strength ~120 MPa after 1000 hours | Superior due to advanced age-hardening process |

| Oxidation Resistance | Good up to 950°C | Excellent up to 950°C with protective coating options | Reduces scaling in corrosive environments |

| Fatigue Life | High in cyclic loading | 20-30% longer under high-temp cycles | Precision manufacturing minimizes defects |

| Wire Diameter Range | 0.1-5 mm | 0.05-10 mm customizable | Wider range for versatile applications |

| Cost-Effectiveness | Standard market rate | Optimized for value with longer service life | Reduces replacement frequency in industries |

Our company's advantages really come through in the details. We don't cut corners on R&D, constantly testing our Nimonic 90 spring wire in simulated high-temp environments to push creep resistance limits. This results in products that exceed standard specs, offering better value through extended service life. Our supply chain is robust, ensuring quick deliveries even amid market fluctuations. Customer support is another win—we provide technical guidance on integration, helping you optimize designs for maximum performance. In a sea of options, our precision-made approach means you're investing in reliability that pays off in reduced operational risks and costs.

Wrapping up, our Precision-Made Nimonic 90 Alloy Spring Wire with Superior Creep Resistance is more than just a product—it's a solution tailored for the future of high-performance engineering. As industries demand more from their materials, we're here delivering the creep-resistant, durable wire that keeps things moving. Whether you're in aerospace tackling efficiency goals or energy pushing sustainability, this alloy wire rises to the occasion. Count on us for the quality, innovation, and support that make a real difference.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Nimonic 90 alloy composed of?

Nimonic 90 is a nickel-chromium-cobalt base alloy strengthened by additions of titanium and aluminum for precipitation hardening.

What are the key properties of Nimonic 90 spring wire?

It offers high creep resistance up to 920°C, excellent oxidation and corrosion resistance, high tensile strength, and good fatigue life in extreme environments.

What applications is Nimonic 90 spring wire used for?

It's ideal for gas turbine components, aerospace engine parts, high-temperature valves, and automotive exhaust systems where durability under heat and stress is critical.

How does Nimonic 90 perform in high-temperature conditions?

The alloy maintains structural integrity with minimal deformation under prolonged stress at temperatures up to 920°C, thanks to its age-hardenable structure.

What industries rely on Nimonic 90 alloy products?

Aerospace, energy production, chemical processing, and automotive sectors use it for components requiring superior heat and creep resistance.

What are current trends in the superalloy industry for materials like Nimonic 90?

There's growing demand for sustainable, high-efficiency alloys in turbine engines and renewable energy applications, with innovations in additive manufacturing and powder metallurgy enhancing performance by 2025.

Why is creep resistance important in Nimonic 90 spring wire?

Creep resistance prevents gradual deformation under constant load at high temperatures, ensuring long-term reliability in dynamic applications like springs and fasteners.

How is Nimonic 90 spring wire manufactured for precision?

Through wrought processing and precision drawing, it achieves uniform diameter, enhanced mechanical properties, and customizable specifications for superior performance.