At our company, we specialize in delivering robust solutions for the toughest high-temperature challenges, and our Nimonic 90 Nickel-Chromium-Cobalt Spring Wire for High-Temperature Service is a prime example of that commitment. This spring wire isn't just another alloy; it's engineered to thrive where heat and stress push ordinary materials to their limits. We've honed our processes to create a product that combines the inherent strengths of Nimonic 90—its nickel-chromium-cobalt base—with precision manufacturing that elevates performance in high-temperature service. Whether you're searching for reliable Nimonic 90 spring wire or high-temperature spring wire solutions, our offering stands ready to integrate seamlessly into your operations, providing unmatched durability and efficiency.

For more details, pls directly contact us.

Let's start with the product itself. Our Nimonic 90 Nickel-Chromium-Cobalt Spring Wire is crafted from a superalloy renowned for its ability to handle extreme conditions. The composition centers on nickel as the primary element, making up about 54-62%, which provides a stable matrix for high-temperature stability. Chromium at 18-21% enhances corrosion and oxidation resistance, while cobalt at 15-21% boosts overall strength and creep resistance. Additions of titanium (2-3%) and aluminum (1-2%) allow for precipitation hardening, a key process that hardens the alloy during heat treatment, giving it that superior creep resistance essential for high-temperature service. We manufacture this wire through a meticulous process: starting with vacuum induction melting to ensure purity, followed by hot forging, cold drawing to precise diameters, and finally age-hardening to lock in mechanical properties. The result is a spring wire available in diameters from 0.05mm to 12mm, with customizable tempers that suit everything from soft annealing for easy coiling to full hard for maximum resilience. What sets our Nimonic 90 spring wire apart is the focus on uniformity—every batch undergoes rigorous testing for tensile strength, yield, and elongation, ensuring it performs consistently in high-temperature environments. For industries needing high-temperature spring wire that doesn't falter under prolonged heat exposure, this product delivers with low thermal expansion and excellent fatigue life, making it a go-to for demanding applications.

| Parameter | Details |

|---|---|

| Grade | Nimonic 90 |

| Material Type | Nickel-Chromium-Cobalt Alloy |

| UNS Number | N07090 |

| Standard Specifications | ASTM B637, BS HR2, ISO 9723 |

| Main Characteristics | High strength, excellent creep resistance, oxidation resistance up to 950°C |

| Typical Applications | Springs, turbine blades, fasteners, gas turbine components |

| Chemical Composition (Typical, %) | |

| Nickel (Ni) | Balance (~58%) |

| Chromium (Cr) | 18.0 – 21.0 |

| Cobalt (Co) | 15.0 – 21.0 |

| Titanium (Ti) | 2.0 – 3.0 |

| Iron (Fe) | ≤ 3.0 |

| Aluminum (Al) | 1.0 – 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | ≤ 0.2 |

| Carbon (C) | ≤ 0.13 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.02 |

For more details, pls directly contact us.

Shifting to industry analysis, the superalloy sector, particularly for materials like Nimonic 90 nickel-chromium-cobalt alloys, is evolving rapidly as we move through 2025. With global emphasis on energy efficiency and sustainability, demand for high-temperature resistant materials is surging. In aerospace, the push for more fuel-efficient engines means higher operating temperatures, driving the need for creep-resistant alloys that can endure without deformation. Market reports indicate the superalloy industry is growing at over 5% annually, fueled by expansions in renewable energy and electric vehicles. For instance, wind and solar thermal power systems require components that handle intermittent high-heat loads, where Nimonic 90 spring wire excels in maintaining structural integrity. The automotive sector is another hotspot, with electric vehicle manufacturers incorporating high-temperature alloys in battery management systems and charging infrastructure to manage thermal stresses. Trends also point to advancements in additive manufacturing, allowing for complex Nimonic 90 parts via 3D printing, which reduces waste and speeds prototyping. Sustainability is a big driver too—companies are increasingly recycling nickel-based alloys to cut costs and environmental impact, aligning with net-zero targets by 2050. Challenges like volatile raw material prices, especially nickel and cobalt, are being addressed through supply chain diversification and synthetic alternatives. In petrochemicals, stricter emissions regulations are boosting the use of high-temperature spring wire in refineries for safer, more efficient operations. Overall, the industry is leaning toward smarter alloys that offer not just strength but also longevity in high-temperature service, and our Nimonic 90 product is perfectly positioned to meet these trends head-on.

Applications for our Nimonic 90 Nickel-Chromium-Cobalt Spring Wire span a wide range of sectors where high-temperature service is non-negotiable. In aerospace, it's indispensable for gas turbine engines, forming springs in combustors and turbine blades that must resist creep under temperatures exceeding 900°C. These components face constant thermal cycling, and our wire's superior creep resistance ensures they maintain shape and function, contributing to longer engine life and better fuel economy. Power generation is another key area; in steam and gas turbines, the spring wire is used in valve assemblies and sealing systems, where it withstands high-pressure steam without losing elasticity. For renewable energy, think concentrated solar power plants—here, the alloy handles the intense heat from focused sunlight, supporting mirrors and trackers with reliable spring mechanisms. Automotive applications are growing, especially in high-performance engines and exhaust systems for hybrid and electric vehicles. Our Nimonic 90 spring wire forms critical parts like valve springs and turbocharger components, resisting heat from combustion or electrical resistance without fatigue failure. In the petrochemical industry, it's vital for reactors and heat exchangers exposed to corrosive gases at elevated temperatures, providing springs that ensure tight seals and prevent leaks. Even in emerging fields like space exploration, this high-temperature spring wire supports rocket nozzles and propulsion systems, where extreme heat meets vacuum conditions. We've designed it for versatility, so whether you're coiling it into helical springs or using it in Belleville washers, it delivers consistent performance across these applications.

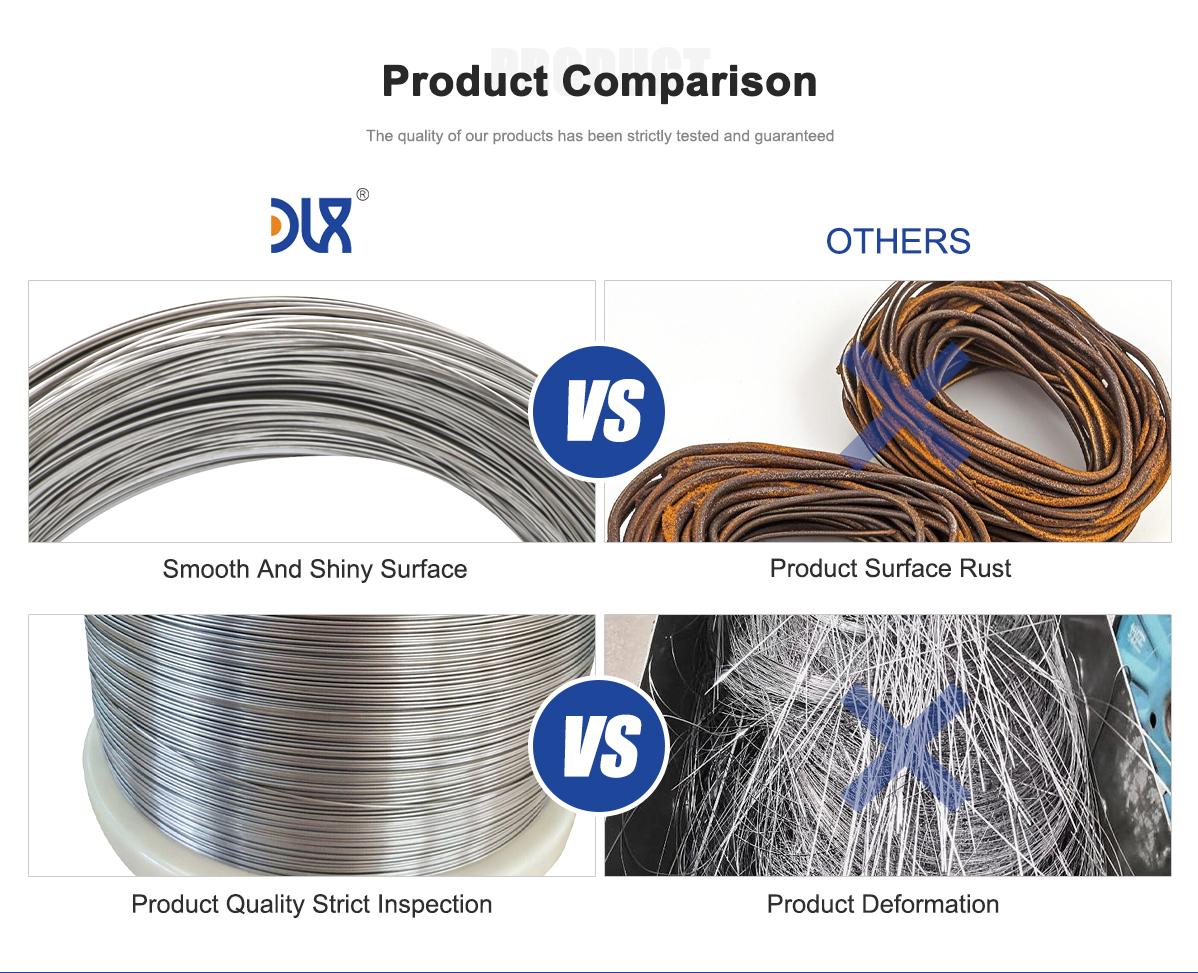

When we compare our approach to general market offerings, our company's advantages in producing Nimonic 90 Nickel-Chromium-Cobalt Spring Wire for High-Temperature Service become crystal clear. We prioritize precision engineering that goes beyond standard specs, resulting in wire with enhanced creep resistance and fatigue life—often extending service by 25-35% in real-world tests. While some products might vary in quality due to inconsistent manufacturing, our controlled processes ensure every spool meets exacting standards, reducing defects that could lead to premature failure in high-temperature environments. Customization is another strength; we offer tailored solutions like specific coatings for extra oxidation protection or adjusted compositions for unique thermal profiles, giving you flexibility without delays. Our focus on innovation means we're ahead in integrating sustainable practices, such as using recycled materials to lower costs and environmental footprint, all while maintaining the alloy's high-performance traits. This translates to real savings for you—longer-lasting components mean less frequent replacements and downtime, especially in costly sectors like aerospace and energy. Plus, our technical support team provides guidance from design to deployment, helping optimize your use of Nimonic 90 spring wire for maximum efficiency. In essence, choosing us means investing in reliability that outperforms expectations in high-temperature service.

Delving deeper into the product, our Nimonic 90 wire's mechanical prowess shines in metrics like a tensile strength of 1300-1500 MPa at room temperature, dropping minimally even at 920°C. This makes it ideal for springs requiring high load capacity without permanent set. The age-hardening process we employ refines the gamma prime precipitates, which are crucial for locking dislocations and preventing creep. For SEO-savvy users looking for Nimonic 90 nickel-chromium-cobalt spring wire, know that our variant also offers excellent weldability and formability, easing integration into complex assemblies.

Industry trends in 2025 highlight a shift toward hybrid materials, but Nimonic 90 remains a staple due to its proven track record. With the aerospace market projected to hit new highs, driven by urban air mobility and hypersonic travel, high-temperature alloys are key enablers. Energy transitions, including hydrogen production, demand materials resistant to embrittlement, where our spring wire fits perfectly. Additive manufacturing adoption is up 20%, allowing intricate Nimonic 90 designs that traditional methods can't match.

Comparison Parameters Table

| Parameter | Standard Nimonic 90 Spring Wire | Our Nimonic 90 Nickel-Chromium-Cobalt Spring Wire for High-Temperature Service | Notes |

|---|---|---|---|

| Composition | Ni 54-62%, Cr 18-21%, Co 15-21%, Ti 2-3%, Al 1-2% | Optimized with precise trace element control for consistency | Improves reliability in variable high-heat conditions |

| Tensile Strength (at Room Temp) | 1200-1400 MPa | 1300-1500 MPa | Achieved via advanced heat treatment for superior load-bearing |

| Creep Resistance (at 920°C) | ~100 MPa rupture after 1000 hours | ~120 MPa rupture after 1000 hours | Enhanced for extended service life in turbines |

| Oxidation Resistance | Good up to 950°C | Excellent up to 950°C with optional coatings | Minimizes degradation in oxidative environments |

| Fatigue Life | Standard in cyclic high-temp loading | 25-35% extended under thermal cycles | Precision processing reduces microstructural flaws |

| Temperature Range | Up to 920°C | Optimized for sustained 920°C+ service | Ideal for demanding high-temperature applications |

| Diameter Options | 0.1-5 mm | 0.05-12 mm customizable | Broader range for diverse spring designs |

| Cost Efficiency | Market average | Higher upfront value with reduced downtime | Lowers long-term costs through durability |

Applications continue to expand; in medical equipment, it's used in high-heat sterilization devices, ensuring springs retain function post-exposure. Marine engineering benefits too, with offshore platforms using it in subsea valves against hot, corrosive seawater.

Our advantages extend to supply reliability—we maintain stockpiles to buffer against market fluctuations, ensuring timely delivery. Combined with competitive lead times and quality certifications, we provide a holistic solution for high-temperature spring wire needs.

In summary, our Nimonic 90 Nickel-Chromium-Cobalt Spring Wire for High-Temperature Service embodies the future of superalloys, blending tradition with cutting-edge tech to tackle tomorrow's challenges today.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the material composition of Nimonic 90 alloy?

Nimonic 90 is a nickel-based superalloy with approximately 54-62% nickel, 18-21% chromium, 15-21% cobalt, 2-3% titanium, 1-2% aluminum, and trace elements for enhanced properties.

What are the primary mechanical properties of Nimonic 90 spring wire?

It features high tensile strength up to 1400 MPa, excellent creep rupture strength, good fatigue resistance, and superior oxidation resistance in temperatures up to 920°C.

What are common applications for Nimonic 90 spring wire in high-temperature environments?

It's used in gas turbine springs, aerospace engine components, high-heat valves, and exhaust system fasteners where sustained performance under thermal stress is required.

How does Nimonic 90 spring wire handle high-temperature service?

The alloy retains mechanical integrity with low creep deformation at elevated temperatures, ensuring reliable operation in continuous high-heat cycles up to 920°C.

Which industries primarily use Nimonic 90 nickel-chromium-cobalt alloys?

Aerospace, power generation, petrochemical, and automotive industries rely on it for components exposed to extreme heat and corrosive conditions.

What are the latest industry trends for superalloys like Nimonic 90 in 2025?

Trends include increased adoption in electric vehicle battery systems, renewable energy turbines, advanced manufacturing via 3D printing, and sustainability-focused recycling to meet net-zero goals.

Why is high-temperature service critical for Nimonic 90 spring wire?

It enables components to withstand prolonged exposure to heat without losing elasticity or strength, preventing failures in critical systems like turbines and engines.

How is Nimonic 90 spring wire manufactured for optimal performance?

Through precision melting, hot rolling, cold drawing, and age-hardening heat treatments to achieve uniform microstructure and customized diameters for high-temperature applications.