High-temperature environments demand materials that can perform reliably without breaking down under stress. Among the top-performing resistance alloys in use today is Cr20Ni80 Nichrome Strip, an alloy known for its excellent stability, high resistivity, and outstanding oxidation resistance. At DLX, we manufacture and supply Cr20Ni80 Nichrome Strip for industries worldwide, focusing on custom solutions that meet the unique demands of high-temperature heating applications.

For more details, pls directly contact us.

Cr20Ni80 is a nickel–chromium alloy made up of approximately 80% nickel and 20% chromium. This high nickel content gives it superior oxidation resistance, mechanical strength, and excellent resistance to scaling at elevated temperatures. Chromium contributes further to oxidation protection and enhances durability in harsh conditions.

This balance of properties makes Cr20Ni80 one of the most reliable resistance alloys for long-term service in heating elements and thermal processing systems. Unlike alloys with lower nickel content, it maintains consistent resistivity even under prolonged high-temperature exposure.

|

Performance / material |

Cr10Ni90 |

Cr20Ni80 |

Cr20Ni35 |

||||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Cr20Ni80 Nichrome Strip is widely used in industries that depend on precision heating and reliable performance:

-

Heating Elements: Ideal for manufacturing custom heating elements in industrial furnaces, kilns, and ovens.

-

Chemical Processing: Applied in environments exposed to aggressive chemicals, ensuring both heat resistance and corrosion protection.

-

Aerospace and Defense: Used in systems that require high-temperature stability and oxidation resistance.

-

Electronics and Laboratory Equipment: Essential for controlled heating applications, such as resistors, thermal instruments, and analytical devices.

-

Energy and Environment: Utilized in renewable energy systems and emission control devices requiring stable high-temperature materials.

By offering Cr20Ni80 in strip form, DLX allows manufacturers to shape, cut, and weld the alloy into designs that fit their specific heating applications.

Industry Trends

The demand for high-performance nickel–chromium alloys is increasing globally, driven by several industry trends:

-

Customization in Manufacturing – More companies require heating systems tailored to unique processes. Cr20Ni80’s adaptability makes it the preferred choice for custom designs.

-

Higher Temperature Demands – As industries push toward faster, hotter processes, materials with stronger oxidation resistance are in greater demand.

-

Focus on Durability and Sustainability – Long service life reduces replacements, downtime, and resource consumption, aligning with global sustainability goals.

-

Expansion of High-Tech Sectors – Aerospace, advanced electronics, and energy industries are investing in materials that ensure performance reliability under extreme conditions.

DLX follows these trends closely and supports clients with innovative solutions that meet evolving requirements.

Why Cr20Ni80 Stands Out

Compared to other resistance alloys, Cr20Ni80 offers unique advantages:

-

Higher Service Temperature: It remains stable up to 1200°C, whereas many alloys degrade below this range.

-

Better Oxidation Resistance: With its high nickel and chromium content, it resists scaling and oxidation more effectively.

-

Stable Resistivity: It maintains electrical stability across thermal cycles, ensuring predictable heating performance.

-

Customizability: It can be manufactured into strips with precise thicknesses and widths, enabling optimized heating designs.

These properties make Cr20Ni80 an ideal material for demanding industries where consistent heating and long service life are critical.

Comparison Table

| Parameter | Cr20Ni80 Nichrome Strip | General Resistance Alloy |

|---|---|---|

| Nickel Content | ~80% | 20–60% |

| Chromium Content | ~20% | 10–25% |

| Max Operating Temperature | Up to 1200°C | 800–1100°C |

| Oxidation Resistance | Excellent | Moderate to Good |

| Electrical Resistivity | High, stable | Lower, less stable |

| Thermal Cycling Stability | Strong | Moderate |

| Customization Options | Wide range available | Limited |

| Service Life | Long-lasting | Shorter |

At DLX, we go beyond simply supplying materials. We focus on ensuring that our clients receive exactly what they need for their high-temperature applications. Our strengths include:

-

Precision Production: We manufacture strips with tight tolerances and consistent surface quality.

-

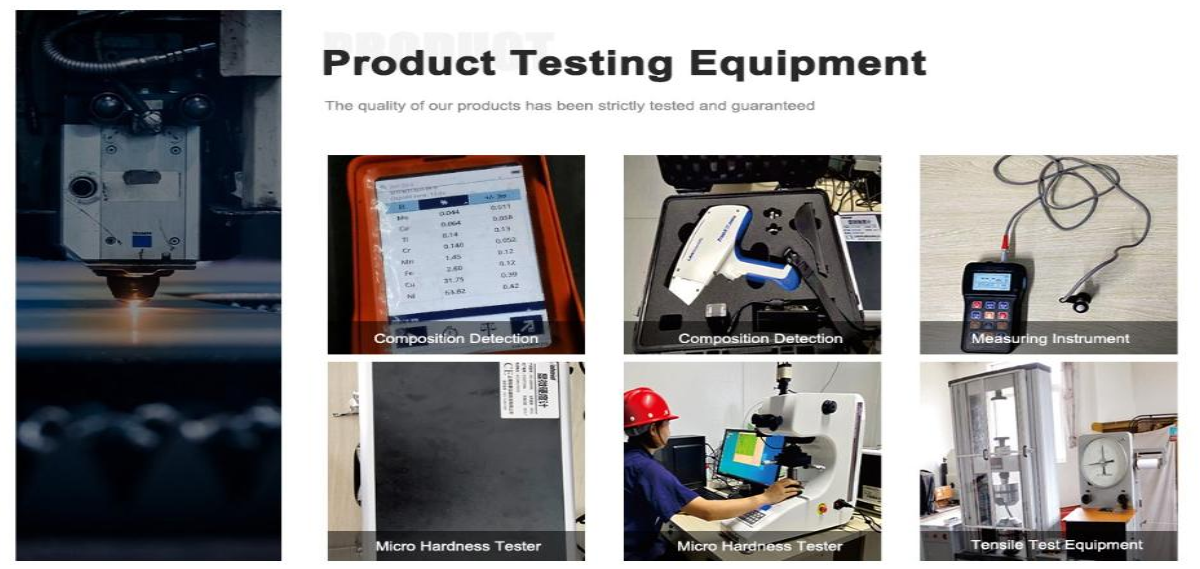

Quality Assurance: Each batch is tested for chemical composition, resistivity, and mechanical properties.

-

Flexible Customization: From small runs for prototypes to bulk production, we adjust to client requirements.

-

Global Delivery: With extensive experience in international trade, DLX ensures efficient logistics and reliable export service.

By combining technical expertise with a customer-first approach, we help clients implement Cr20Ni80 Nichrome Strip into their systems with confidence.

Applications in Real Equipment

The practical uses of Cr20Ni80 highlight its value:

-

In industrial furnaces, it provides long-lasting heating elements that resist scaling over thousands of cycles.

-

In chemical plants, it endures corrosive conditions while maintaining thermal stability.

-

In aerospace systems, it ensures reliability under fluctuating thermal loads.

-

In laboratory devices, it delivers consistent performance for precision experiments.

Each of these applications benefits from the strip form, which can be cut and formed to match custom designs.

The demand for Cr20Ni80 Nichrome Strip is set to increase as industries continue to evolve. Sectors such as aerospace, energy, and environmental engineering will rely even more on alloys that provide durability, thermal stability, and customization potential.

As clients seek suppliers who can combine material quality with expertise and dependable service, DLX is positioned to lead. We are investing in advanced production technologies and strengthening our export capabilities to meet the growing global demand.

Cr20Ni80 Nichrome Strip is a top-performing alloy for custom high-temperature heating designs. With its high nickel content, excellent oxidation resistance, and stability under thermal cycling, it outperforms many other resistance alloys. At DLX, we ensure that our customers receive this material with the highest level of precision, quality, and service. As industries push toward more advanced heating applications, Cr20Ni80 will continue to be the alloy of choice—and DLX will continue to be the partner that delivers it.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Q1: What is the composition of Cr20Ni80 Nichrome Strip?

A1: It contains about 80% nickel and 20% chromium.

Q2: What industries use Cr20Ni80 Nichrome Strip the most?

A2: It is commonly used in heating elements, chemical processing, aerospace, and laboratory equipment.

Q3: What is the maximum operating temperature of Cr20Ni80 Nichrome Strip?

A3: It can operate continuously up to around 1200°C.

Q4: Does Cr20Ni80 Nichrome Strip resist oxidation at high heat?

A4: Yes, it has excellent oxidation resistance and stability in air at elevated temperatures.

Q5: Can Cr20Ni80 Nichrome Strip be customized for different heating designs?

A5: Yes, it can be manufactured in various thicknesses, widths, and surface finishes.

Q6: How does Cr20Ni80 perform under thermal cycling?

A6: It shows strong stability and long service life under repeated heating and cooling cycles.

Q7: What are the main advantages of Cr20Ni80 compared to lower nickel alloys?

A7: It offers higher electrical resistivity, better oxidation resistance, and longer life at high temperatures.

Q8: Why choose DLX as a supplier of Cr20Ni80 Nichrome Strip?

A8: DLX provides strict quality control, precision customization, and global delivery solutions.