Materials matter when performance and safety are on the line. In marine environments where saltwater and moisture create relentless corrosion challenges, and in industrial systems that demand stability at high temperatures, the choice of alloy becomes critical. Among the best solutions available today is the Cr15Ni60 Nichrome Strip . At DLX, we manufacture and supply this alloy with precision, ensuring that our customers achieve dependable results in both marine and industrial applications.

For more details, pls directly contact us.

Cr15Ni60 is a nickel–chromium alloy with around 60% nickel and 15% chromium. This composition creates a powerful balance: nickel ensures toughness and corrosion resistance, while chromium provides oxidation resistance at high temperatures. Unlike standard stainless steels, Cr15Ni60 is engineered to handle both saline environments and elevated thermal conditions without losing mechanical or electrical stability.

Its electrical resistivity also makes it ideal for resistance heating applications, while its mechanical strength supports long-term durability in aggressive conditions. For industries that operate under demanding conditions, Cr15Ni60 is a material that performs consistently.

Performance / material | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | ||

Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

Resistivity at 20℃ (μΩ·m) | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

Specific heat (J/g.℃) | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

Thermal conductivity (KJ/m.h℃) | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

Coefficient of lines expansion a×10-6/(20~1000℃) | -- | 18 | 17 | 17 | 19 | 19 | |

Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

Magnetic properties | -- | Non-magnetic | Non-magnetic | Non-magnetic | Weak magnetic | Weak magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-40) |

For more details, pls directly contact us.

The versatility of Cr15Ni60 Nichrome Strip makes it an essential material across a wide range of sectors:

Marine Engineering: Used in ship components, offshore structures, and desalination plants where seawater resistance is critical.

Chemical Processing: Applied in equipment that handles corrosive chemicals, ensuring stability and long service life.

Electrical Heating Systems: Commonly used in resistive heating elements where stable performance under thermal cycling is vital.

Thermal Processing Equipment: Found in kilns, industrial ovens, and heat-treatment systems where durability at high temperatures is required.

Environmental Systems: Utilized in emission control devices and waste processing equipment, where oxidation and corrosion resistance are priorities.

This combination of marine-grade corrosion resistance and thermal stability sets Cr15Ni60 apart from general-purpose alloys.

Industry Trends

Several global trends are shaping the increasing demand for Cr15Ni60 Nichrome Strip:

Growth in Marine Infrastructure – With continued investment in offshore energy, shipping, and desalination, the need for marine-grade alloys is expanding.

High-Temperature Manufacturing – Industries that rely on furnaces, ovens, and kilns are pushing for alloys that can sustain longer life cycles under constant heat.

Sustainability Goals – Companies seek materials that reduce downtime, replacement frequency, and maintenance costs. Cr15Ni60 offers long-lasting performance, supporting these goals.

Global Energy Shift – As renewable energy and chemical industries expand, demand for resistant, stable alloys continues to rise.

By staying aligned with these developments, DLX is able to support customers worldwide with material solutions that meet both current and future challenges.

Why Cr15Ni60 Stands Out

Compared to stainless steels or lower nickel alloys, Cr15Ni60 provides distinct advantages. Its nickel-rich composition ensures superior resistance to chloride stress corrosion cracking, a common problem in marine settings. Its ability to maintain structural integrity at temperatures above 1000°C also makes it more reliable than many alternatives.

For customers, this translates into longer service life, less maintenance, and improved operational efficiency. Whether in a desalination plant exposed to seawater or a furnace operating at continuous high temperatures, Cr15Ni60 delivers reliable performance where it matters most.

DLX Company Perspective

At DLX, we understand that supplying material is only part of the job. Customers require more than just alloy strips; they need confidence in quality, consistency, and service. That’s where our strengths shine:

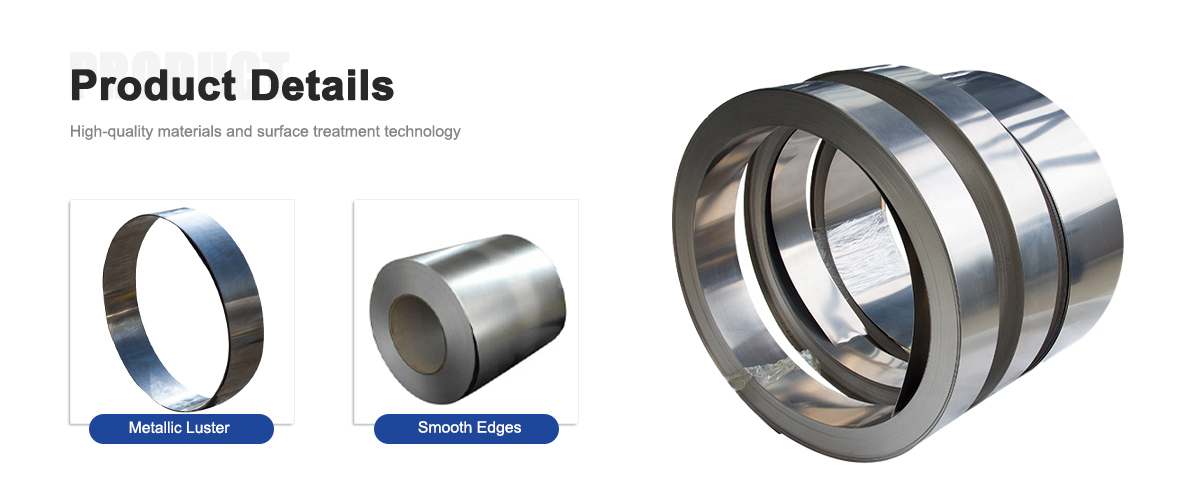

Precision Manufacturing: We control thickness, width, and surface finish to meet exacting industry standards.

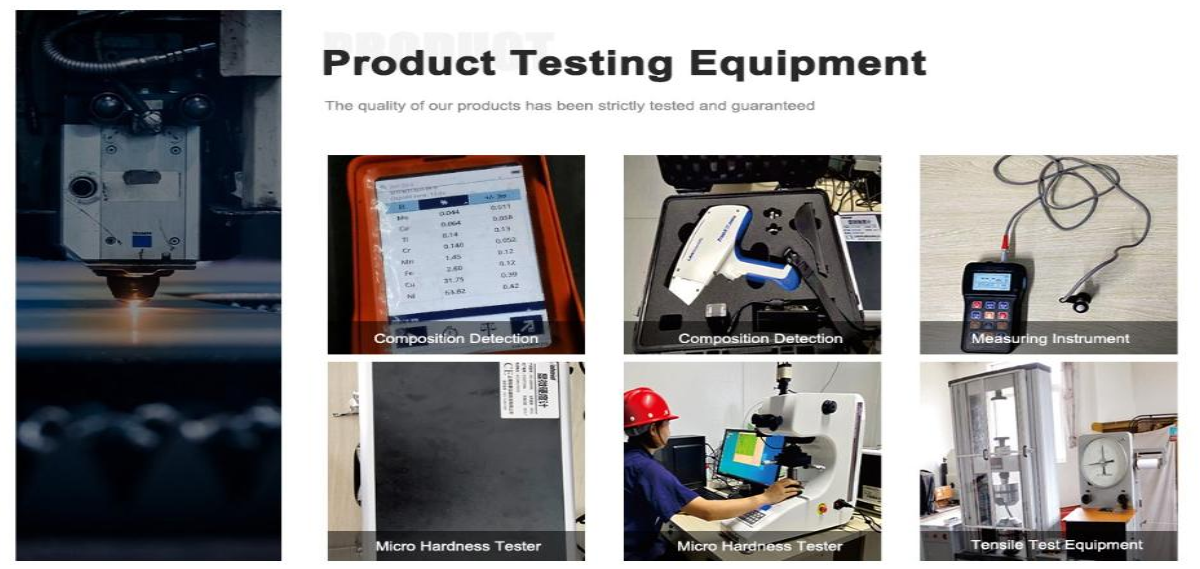

Strict Quality Assurance: Every production batch undergoes full chemical analysis, mechanical testing, and visual inspection.

Customization Options: From narrow precision strips to wider industrial formats, we adapt to client specifications.

Global Logistics Support: With years of export experience, DLX ensures that deliveries are secure, compliant, and on schedule.

Our goal is to provide customers with not just a material, but a complete solution that improves their long-term operations.

Comparison Table

| Parameter | Cr15Ni60 Nichrome Strip | General Stainless Steel Strip |

|---|---|---|

| Nickel Content | ~60% | 8–12% |

| Chromium Content | ~15% | 16–20% |

| Max Operating Temperature | Up to 1100°C | Up to 800°C |

| Oxidation Resistance | Excellent | Good |

| Marine Corrosion Resistance | High | Moderate |

| Electrical Resistivity | High, stable | Low, not stable |

| Thermal Stability | Strong under cycling | Moderate |

| Service Life | Long-lasting | Shorter under stress |

Consider how Cr15Ni60 Nichrome Strip is applied in practice. In marine desalination units, it withstands continuous exposure to high-salinity water without pitting or cracking. In offshore energy structures, it resists the combined effects of salt spray, humidity, and temperature fluctuations. In industrial heating elements, it operates for thousands of cycles without drift in resistance, ensuring consistent heat output.

By supplying strip form, DLX provides manufacturers with flexibility. Clients can cut, weld, and shape Cr15Ni60 into the specific components required for their systems, confident in the material’s reliability.

Looking forward, the importance of Cr15Ni60 Nichrome Strip is only set to grow. With the expansion of global shipping, marine renewable energy, and advanced processing industries, the demand for marine-grade alloys is increasing steadily. Customers will also continue to prioritize suppliers who can combine material quality with technical expertise and dependable logistics.

DLX is prepared to meet this demand. By investing in advanced production technologies and maintaining a strong customer-focused approach, we ensure that our Cr15Ni60 Nichrome Strip remains a trusted solution for clients worldwide.

Cr15Ni60 Nichrome Strip is more than just a resistance alloy; it is a high-performance material designed to thrive in some of the harshest conditions on earth. With its unique blend of corrosion resistance, oxidation stability, and durability, it is an ideal choice for marine applications and beyond. At DLX, we take pride in supplying this alloy with precision and reliability, helping industries achieve better performance and longer service life. As global industries move toward more demanding environments, Cr15Ni60 will remain a critical material—and DLX will continue to be a trusted partner in delivering it.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Q1: What is the chemical composition of Cr15Ni60 Nichrome Strip?

A1: It contains about 60% nickel and 15% chromium, with balance elements like iron.

Q2: What industries commonly use Cr15Ni60 Nichrome Strip?

A2: It is widely applied in marine equipment, chemical processing, heating systems, and electrical resistance applications.

Q3: Why is Cr15Ni60 Nichrome Strip considered marine-grade?

A3: Its chromium and nickel balance provides strong resistance against seawater and saline environments.

Q4: What is the maximum working temperature of Cr15Ni60 Nichrome Strip?

A4: It can operate effectively up to 1100°C under continuous service.

Q5: Can Cr15Ni60 Nichrome Strip be welded and fabricated easily?

A5: Yes, it offers good weldability and formability for different industrial uses.

Q6: How does Cr15Ni60 perform under corrosive conditions?

A6: It shows excellent resistance to oxidation, scaling, and chloride-induced corrosion.

Q7: What are the main advantages of Cr15Ni60 over general stainless steel strips?

A7: It has higher electrical resistivity, better thermal stability, and longer service life in harsh environments.

Q8: Why choose DLX as a supplier of Cr15Ni60 Nichrome Strip?

A8: DLX delivers consistent quality, customized production, and reliable export service for global industries.