When it comes to demanding environments like chemical plants, furnaces, and high-temperature systems, the choice of material makes the difference between long service life and premature failure. One of the most reliable materials in this field is the Cr30Ni70 Nichrome Strip, an alloy designed to withstand heat, corrosion, and mechanical stress over time. At DLX, we focus on delivering this alloy in strip form with the highest precision, ensuring customers achieve efficiency and reliability in their equipment.

For more details, pls directly contact us.

Cr30Ni70 is a nickel–chromium alloy containing about 70% nickel and 30% chromium. This balance of elements gives it a unique set of properties: high resistivity, superior oxidation resistance, and outstanding stability in chemical processing environments. Unlike some alloys that break down under repetitive heating and cooling cycles, Cr30Ni70 maintains its structure and resistivity, which is why it is favored for long-lasting components.

|

Performance / material |

Cr10Ni90 |

Cr20Ni80 |

Cr30Ni70 |

Cr20Ni30 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

The versatility of Cr30Ni70 Nichrome Strip makes it a key material in several industries:

-

Chemical Processing Equipment: Used for reactors, heating elements, and corrosion-resistant linings, ensuring stable performance in acidic and alkaline environments.

-

Furnace Components: Applied in radiant tubes, muffles, and furnace belts that demand high strength and long life at elevated temperatures.

-

Electrical Heating Systems: A go-to material for resistive heating elements where stability and longevity are essential.

-

Thermal Processing: In kilns, dryers, and industrial ovens, it delivers consistent heating performance without degradation.

By offering Cr30Ni70 Nichrome Strip in customized sizes and surface finishes, DLX meets the specific needs of each industry segment.

Industry Trends

Global demand for nickel–chromium alloys is rising, especially in the energy, chemical, and environmental sectors. Several trends are driving this growth:

-

Sustainability in Manufacturing – Industries require alloys that last longer, reduce downtime, and minimize waste. Cr30Ni70 fits these demands perfectly.

-

Advanced Thermal Processing – As production equipment operates at higher temperatures, the need for alloys with strong oxidation resistance is increasing.

-

Chemical Industry Expansion – With continuous investment in chemical and petrochemical facilities, the demand for corrosion-resistant alloys is expected to remain strong.

-

Export Growth – Countries focusing on renewable energy and advanced manufacturing are investing heavily in materials like Cr30Ni70.

DLX is aligned with these trends by offering high-quality production and global export services, ensuring that clients stay ahead of market demands.

Why Cr30Ni70 Stands Out

Compared to general resistance alloys, Cr30Ni70 offers several distinct advantages. Its higher nickel content boosts strength and corrosion resistance, while chromium contributes to superior oxidation resistance. The result is an alloy that performs consistently even in the most aggressive environments. For customers in chemical processing, this means fewer replacements, less downtime, and reduced operating costs.

DLX Company Perspective

At DLX, we take pride in our expertise in producing Cr30Ni70 Nichrome Strip. Our advantage lies not just in supplying material but in ensuring clients receive tailored solutions:

-

Precision Manufacturing – We produce strips with tight tolerances in thickness, width, and surface finish, meeting exact industry specifications.

-

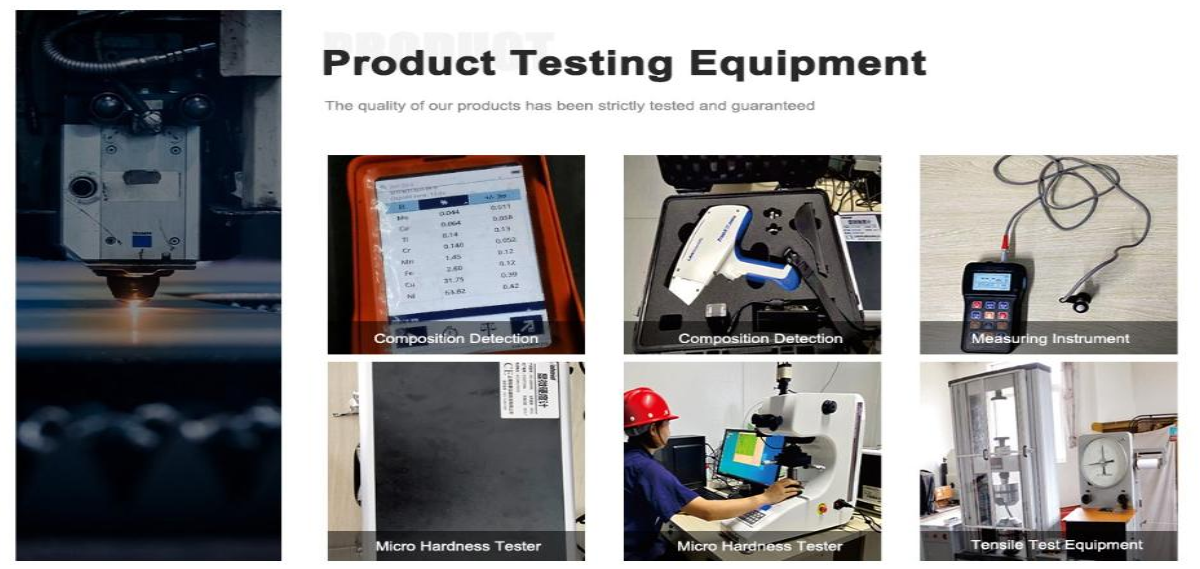

Strict Quality Control – Each batch undergoes rigorous inspection, including chemical composition analysis, mechanical testing, and surface quality checks.

-

Customization – From small prototype orders to large-scale production runs, we adapt our supply to meet client requirements.

-

Global Service – With years of experience in international trade, DLX ensures reliable logistics and export compliance.

These advantages translate into long-term trust from our customers worldwide, particularly in sectors where material performance is critical.

One of the strengths of Cr30Ni70 Nichrome Strip is how it integrates into equipment. For example, in chemical reactors exposed to acidic solutions, it prevents corrosion that would otherwise compromise safety and efficiency. In high-temperature furnaces, it maintains its structural integrity even after thousands of heating cycles. In resistive heating systems, it delivers stable performance without drift, ensuring predictable output.

By supplying strip material, DLX gives manufacturers the flexibility to shape, cut, or weld the alloy into whatever form their equipment requires.

Comparison Table

| Parameter | Cr30Ni70 Nichrome Strip | General Resistance Alloy |

|---|---|---|

| Nickel Content | ~70% | 20–60% |

| Chromium Content | ~30% | 10–25% |

| Maximum Operating Temp. | Up to 1200°C | 800–1100°C |

| Oxidation Resistance | Excellent | Moderate to Good |

| Corrosion Resistance | Strong in chemicals | Moderate |

| Electrical Resistivity | Stable under load | Less stable |

| Mechanical Strength | High, durable | Moderate |

| Service Life | Long-lasting | Shorter under stress |

The demand for Cr30Ni70 Nichrome Strip is expected to keep growing as industries focus on energy efficiency and durability. Customers are increasingly looking for suppliers who not only provide material but also technical expertise, fast delivery, and after-sales support. DLX is positioned to meet these expectations, with an expanding product portfolio and strong investment in advanced manufacturing.

Cr30Ni70 Nichrome Strip is a proven choice for long-lasting chemical processing equipment and high-temperature applications. Its unique combination of nickel and chromium provides strength, stability, and resistance that other alloys simply cannot match. At DLX, we continue to refine our processes to deliver the best possible material, helping clients achieve efficiency and reliability in their operations. With industry trends pointing toward greater reliance on high-performance alloys, Cr30Ni70 is set to play an even bigger role in the future—and DLX is ready to lead the way.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Q1: What is Cr30Ni70 Nichrome Strip made of?

A1: It is composed of approximately 30% chromium and 70% nickel.

Q2: What industries commonly use Cr30Ni70 Nichrome Strip?

A2: It is widely used in chemical processing, thermal equipment, furnace components, and electrical resistance applications.

Q3: Does Cr30Ni70 Nichrome Strip resist oxidation at high temperatures?

A3: Yes, it has excellent oxidation resistance even at elevated temperatures.

Q4: How durable is Cr30Ni70 Nichrome Strip in corrosive environments?

A4: It offers long-lasting performance due to its superior corrosion resistance in harsh chemical environments.

Q5: What forms are available for Cr30Ni70 Nichrome material?

A5: It can be supplied in strip, wire, rod, and tube forms depending on customer requirements.

Q6: Can Cr30Ni70 Nichrome Strip be welded easily?

A6: Yes, it has good weldability and can be fabricated with standard techniques.

Q7: What is the main advantage of Cr30Ni70 over other resistance alloys?

A7: It combines high strength, long service life, and resistance stability under thermal cycling.

Q8: Why choose DLX for Cr30Ni70 Nichrome Strip supply?

A8: DLX offers precise manufacturing, strict quality control, and global export service tailored to client needs.